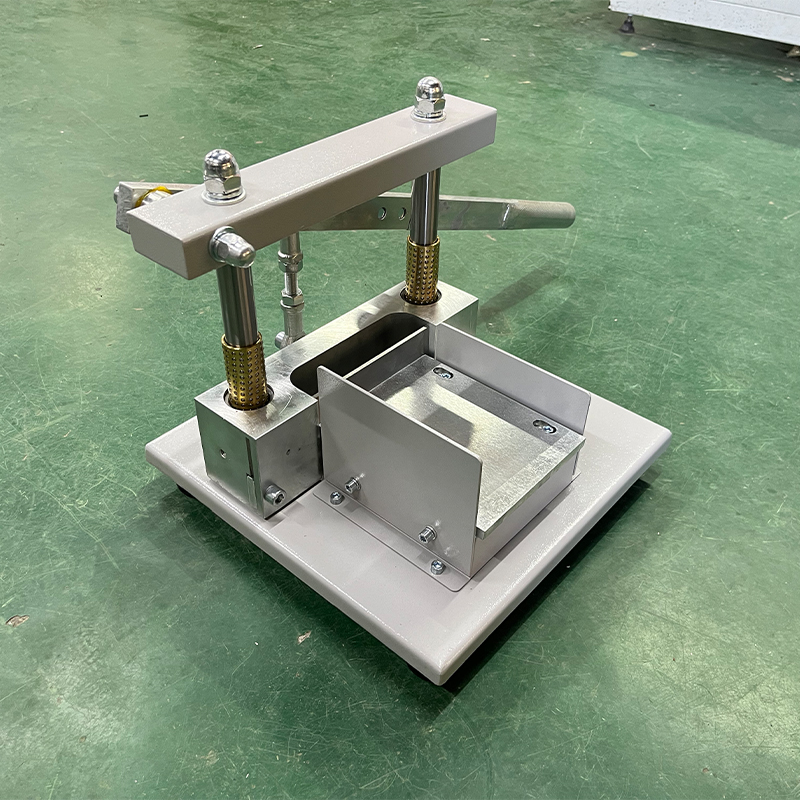

wire and cable testing machine

In the intricate world of electronics and electrical infrastructure, the importance of reliable wire and cable systems cannot be overstated. These systems are the backbone of modern technology, ensuring that electrical currents and data transmissions occur seamlessly. Yet, behind every dependable wire and cable is a robust testing process, overseen by cutting-edge wire and cable testing machines. These devices ensure that products meet both safety standards and performance expectations, elevating the end-user experience through superior quality assurance.

Wire and cable testing machines have evolved into sophisticated devices capable of assessing various essential parameters. Their functions range from measuring electrical properties such as conductivity and resistance, to physical characteristics like tensile strength and insulation integrity. This diversity in testing capabilities highlights the expertise embedded in modern manufacturing processes. The design and functionality of these machines are based on extensive research and development conducted by industry leaders who possess a deep understanding of the complexities of wire and cable performance.

Trustworthiness in wire and cable testing begins with transparency in the testing methodology. Competent testing laboratories provide detailed reports outlining each test conducted, accompanied by standardized metrics. These reports offer manufacturers and consumers reassurance that the products have been tested rigorously and meet prescribed international or regional standards. The credibility of these tests is often fortified by third-party certifications, which add an extra layer of authoritativeness to the machine's results.

Additionally, the user experience offered by modern wire and cable testing machines has been significantly enhanced through intuitive interfaces and automation. With the advent of user-friendly software and real-time data analysis, operators with varying expertise levels can efficiently perform complex testing procedures. This automation reduces human error, ensuring precision and reliability in test results, thus delivering a credible promise of product safety and performance.

From a professional perspective, these machines represent both innovation and responsibility. Manufacturers and quality control specialists rely on their expertise to interpret results accurately and make informed decisions about product quality. Continuous training and certification ensure that operators maintain a high level of competence, further contributing to the machines' authoritative role in the wire and cable industry.

wire and cable testing machine

Moreover, authority in this sector is often established through longstanding relationships with industry bodies and adherence to evolving standards. Producers of wire and cable testing machines frequently collaborate with professional organizations to stay at the forefront of technological advancements and regulatory changes. These partnerships help in crafting testing methodologies that are not just compliant but also predictive of future industry trends.

Experience is another pillar that underpins the reliability of these testing systems. Many machines are born out of decades of hands-on experience, leading to refined technologies that address specific industry challenges. Lessons learned from field applications influence the design and functionality of new models, ensuring that they meet practical needs while also pushing the boundaries of what's technically possible.

Furthermore, feedback loops from end-users contribute significantly to the machines' evolution. By listening to those who use these machines daily, manufacturers gain insights that drive enhancements and innovation, aligning machine capabilities with real-world testing scenarios. This user-centric development approach results in machines that not only deliver precise testing outcomes but also adapt to the changing landscape of wire and cable technology.

In summary, wire and cable testing machines are integral to the assurance of product quality and safety in the electrical and electronics industries. They embody a blend of experience, expertise, authority, and trustworthiness, ensuring that every product reaching the end-user is both safe and reliable. As technology continues to evolve, these machines will remain at the heart of quality assurance, adapting and advancing to meet new demands and standards.

-

reliable-performance-testing-with-advanced-aging-chamber-solutions

NewsAug.23,2025

-

advancing-precision-with-profile-projector-technology

NewsAug.23,2025

-

uv-led-ultraviolet-crosslinking-technology-innovation-and-prospects

NewsAug.23,2025

-

ensuring-safety-and-compliance

NewsAug.23,2025

-

electrical-properties-testing-in-modern-applications

NewsAug.23,2025

-

universal-tensile-testing-machine-applications-in-modern-electrical-and-material-testing

NewsAug.23,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy