Cable Burning Test Equipment Manufacturers for Safety and Performance Evaluation

Cable Combustion Testing Machine Manufacturers Ensuring Safety in Electrical Components

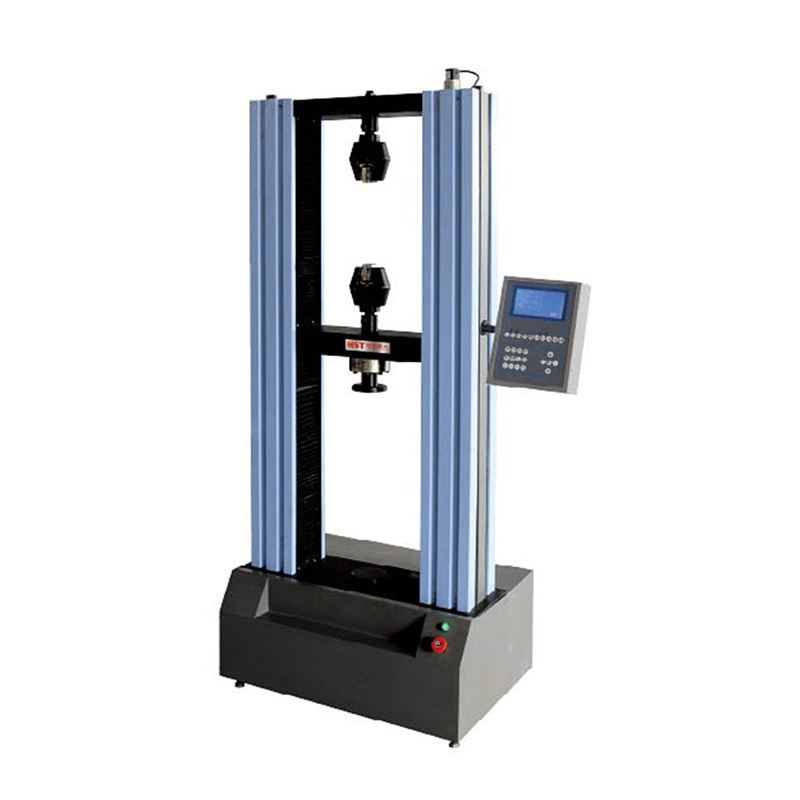

In an era where safety standards are paramount, the demand for reliable cable combustion testing machines has surged. These machines are essential for evaluating the flammability and combustion characteristics of cable materials, ensuring they meet industry regulations and standards. The role of cable combustion testing machine manufacturers is critical in this landscape, as they provide the tools necessary for testing the safety and durability of electrical cables.

Cable combustion testing machines are specifically designed to assess the burning behavior of various cable materials, including insulation and sheathing. By simulating real-life conditions that cables might face during a fire, these machines allow manufacturers to anticipate and mitigate potential hazards. The testing process involves exposing samples to controlled flames, observing burn rates, smoke production, and the release of harmful gases. This comprehensive analysis is vital for compliance with international standards such as UL, IEC, and BS, which dictate the safety requirements for electrical products.

Leading cable combustion testing machine manufacturers utilize advanced technology to ensure precision and reliability in their testing procedures. Features such as digital monitoring systems, programmable settings, and automated data recording are common in modern machines. These advancements streamline the testing process, reduce the risk of human error, and enhance repeatability, leading to more consistent results. Manufacturers also prioritize user-friendly interfaces, allowing technicians to operate the machines with ease while adhering to strict safety protocols.

cable combustion testing machine manufacturers

Furthermore, manufacturers place a strong emphasis on innovation and research. As new materials and manufacturing techniques emerge, the testing requirements evolve accordingly. Companies that invest in research and development can create more sophisticated testing solutions that address the changing needs of the industry. For instance, the rise of eco-friendly materials has prompted manufacturers to design testing machines capable of evaluating biopolymers and other sustainable materials, ensuring they also comply with safety standards.

In addition to providing state-of-the-art equipment, reputable manufacturers offer comprehensive support to their clients. This includes training on machine operation, guidance on conducting tests, and assistance with interpreting results. Such support is crucial for companies aiming to enhance their product safety and remain competitive in the market.

In conclusion, cable combustion testing machine manufacturers play a vital role in safeguarding the electrical industry. By providing advanced testing solutions, they help ensure that cables not only meet regulatory requirements but also protect consumers from potential fire hazards. As the industry continues to evolve, these manufacturers will remain at the forefront, driving innovation and promoting safety in electrical components worldwide.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy