cable hot set testing suppliers

Understanding Cable Hot Set Testing and the Suppliers Behind It

In the world of electrical engineering and manufacturing, ensuring that cables can withstand the rigors of heavy usage and extreme conditions is paramount. One of the essential tests performed on these cables is the Hot Set Test. This testing method assesses the heat resistance and durability of electrical cables when subjected to elevated temperatures. As industries depend on reliable cable suppliers, understanding the Hot Set Test and the suppliers who specialize in this arena is crucial for maintaining quality and safety standards.

What is Hot Set Testing?

Hot Set Testing is a method used to evaluate the thermal properties of polymeric materials used in electrical cables. The test involves exposing a sample cable to a high-temperature environment for a specified duration while applying a predetermined amount of tension. After the exposure, the cable is cooled, and its ability to return to its original shape is assessed. This test helps determine the cable's heat resistance, mechanical properties, and its ability to handle thermal expansion or contraction.

The importance of this test cannot be overstated. With the rise of renewable energy sources and advancements in technology, cables are being subjected to more extreme conditions than ever before. Without rigorous testing, the risk of failure increases, which can lead to significant safety hazards and costly downtime for industries reliant on these cables.

The Role of Suppliers in Hot Set Testing

Various suppliers specialize in providing testing equipment and materials for Hot Set Testing. These suppliers play a crucial role in ensuring that manufacturers can conduct accurate and efficient tests. They offer a range of products, including

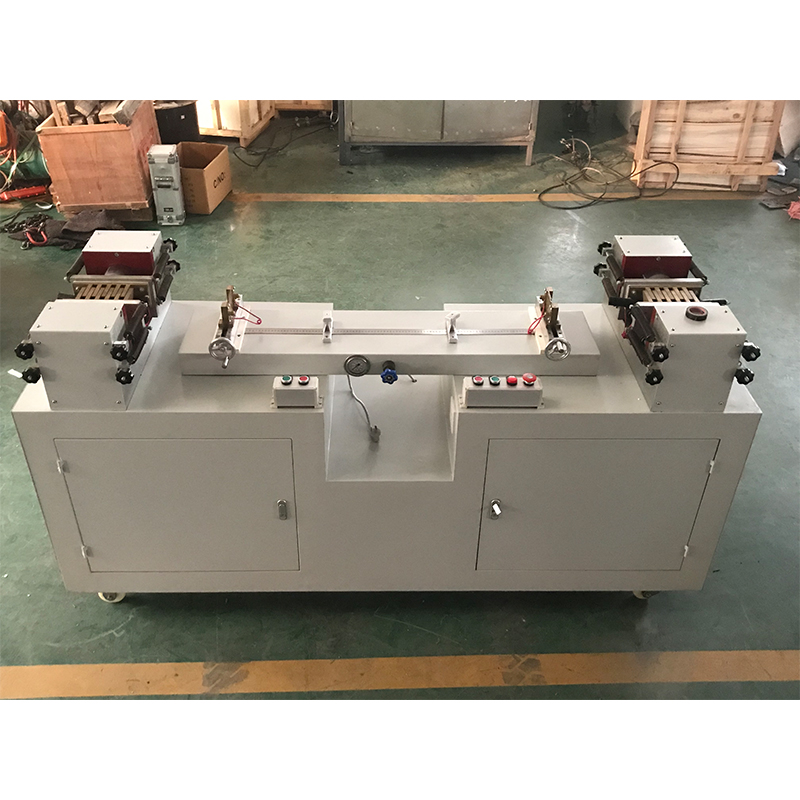

1. Testing Machines These machines are designed to maintain specific temperatures and apply consistent tension to the cable samples. High-quality testing machines provide precise control over conditions, ensuring reliable test results.

2. Calibration Services Suppliers often offer calibration services for testing machines to ensure they meet industry standards. Accurate calibration is vital to obtaining valid and reproducible results.

3. Training and Support Many suppliers provide training programs for manufacturers, educating them on proper testing procedures and the importance of maintaining equipment for consistent results.

cable hot set testing suppliers

4. Consultation Services Some suppliers offer expert consultation on testing parameters and can help manufacturers design custom testing regimes tailored to their cables' specific applications.

Choosing the Right Supplier

When selecting a supplier for cable Hot Set Testing, manufacturers should consider several factors

- Reputation and Experience Established suppliers with a proven track record in the industry often provide higher-quality equipment and support. Researching customer reviews and case studies can provide valuable insights.

- Certification and Compliance Ensure that the supplier adheres to industry standards and certifications. This compliance is crucial for maintaining quality assurance in testing procedures.

- Technical Support Suppliers who offer ongoing technical support and consultation can be invaluable, especially for manufacturers new to Hot Set Testing.

- Product Range A supplier that provides a broad range of testing equipment and accessories allows manufacturers to address all their testing needs in one place.

Conclusion

Cable Hot Set Testing is an indispensable process in the manufacture of reliable electrical cables. As industries continue to evolve and adapt, the demand for durable and efficient cables will only increase. By working with trusted suppliers who specialize in testing equipment and support, manufacturers can ensure their products meet safety and performance standards. Proper selection of these suppliers ultimately leads to increased confidence in product quality and a reduction in failures, benefiting both manufacturers and end-users alike. As we advance further into an electrified future, the role of effective Hot Set Testing and its suppliers will remain at the forefront of ensuring electrical safety and reliability.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy