High Insulation Resistance Testing Solutions from Leading Manufacturers for Optimal Performance

High Insulation Resistance Test Importance, Methods, and Leading Manufacturers

In an increasingly electrified world, maintaining safe and reliable electrical systems has never been more critical. One of the key metrics that help ensure the safety and performance of electrical equipment is insulation resistance. High insulation resistance implies that current flows are confined within desired pathways, minimizing the likelihood of short circuits, equipment failure, or even dangerous electrical shocks. To ascertain the integrity of an electrical system, rigorous testing and analysis are essential, making high insulation resistance testing an integral part of maintenance and safety protocols.

What is Insulation Resistance?

Insulation resistance is the ability of an insulating material to resist electrical current. It is primarily measured in ohms (Ω) and reflects the quality of the insulation that surrounds electrical conductors. A higher insulation resistance value indicates better performance and safety of the electrical system, while lower values can signify potential issues such as insulation degradation, moisture ingress, or physical damage.

Importance of High Insulation Resistance Testing

The significance of high insulation resistance testing cannot be overstated. Regular tests are crucial for

1. Safety Regular testing helps identify weak points in insulation, reducing the risk of electric shocks and fires caused by short circuits.

2. Equipment Longevity High insulation resistance can indicate that equipment is functioning optimally. Prolonged usage of equipment with low insulation resistance can lead to extensive damage, resulting in increased maintenance costs or premature failure.

3. Regulatory Compliance Many industries are subject to strict safety regulations regarding electrical installations. High insulation resistance testing ensures compliance with standards and regulations, protecting organizations from potential penalties.

4. Operational Reliability By identifying insulation failures before they escalate, organizations can avoid unscheduled downtime, thus improving productivity and reliability in operations.

Testing Methods

There are several methods utilized in high insulation resistance testing

high insulation resistance test manufacturer

1. Megger Testing This method involves using a megohmmeter (commonly referred to as a megger) that applies a high voltage (typically 250V to 1000V) to the insulation. The resistance is then measured, and values are compared to industry standards or historical data.

2. Digital Insulation Resistance Testers These modern testers offer enhanced features, including digital displays and the ability to record and analyze data over time. Many come equipped with safety features to prevent overloading and ensure operator safety.

3. Thermal Imaging While not a direct method for measuring insulation resistance, thermal imaging can complement traditional testing methods. By identifying hot spots in electrical systems, it can signal potential insulation failures and facilitate further investigation.

Leading Manufacturers in High Insulation Resistance Testing

When it comes to selecting equipment for high insulation resistance testing, quality manufacturers play a crucial role. Several companies have established themselves as leaders in the field

1. Fluke Corporation Renowned for its reliable and advanced electrical testing equipment, Fluke offers a variety of insulation testers, known for their durability and accuracy. Their devices often come equipped with features like data logging and connectivity options for enhanced analysis.

2. Megger Group As the name suggests, Megger is synonymous with insulation testing. The company boasts a long history in the industry and offers a wide range of insulation resistance testers tailored for different applications, from handheld units to more complex systems.

3. Ametek A leading player in electronic instruments, Ametek offers high-quality insulation resistance testers. Their devices are designed for professionals demanding accuracy and reliability in measurement.

4. Gossen Metrawatt This German manufacturer specializes in electrical testing instruments, including insulation resistance testers that cater to various international safety standards and operational needs.

Conclusion

High insulation resistance testing is a non-negotiable aspect of electrical safety, performance, and compliance. With its importance underscored in increasing electrical application, selecting the appropriate testing methods and reliable manufacturers is essential for maintaining the integrity of electrical systems. Regular assessments can ultimately contribute to safer work environments, enhanced equipment longevity, and improved operational reliability. As technology continues to advance, the tools and methods for insulation resistance testing are poised to become even more sophisticated, ensuring that safety remains at the forefront of electrical engineering.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

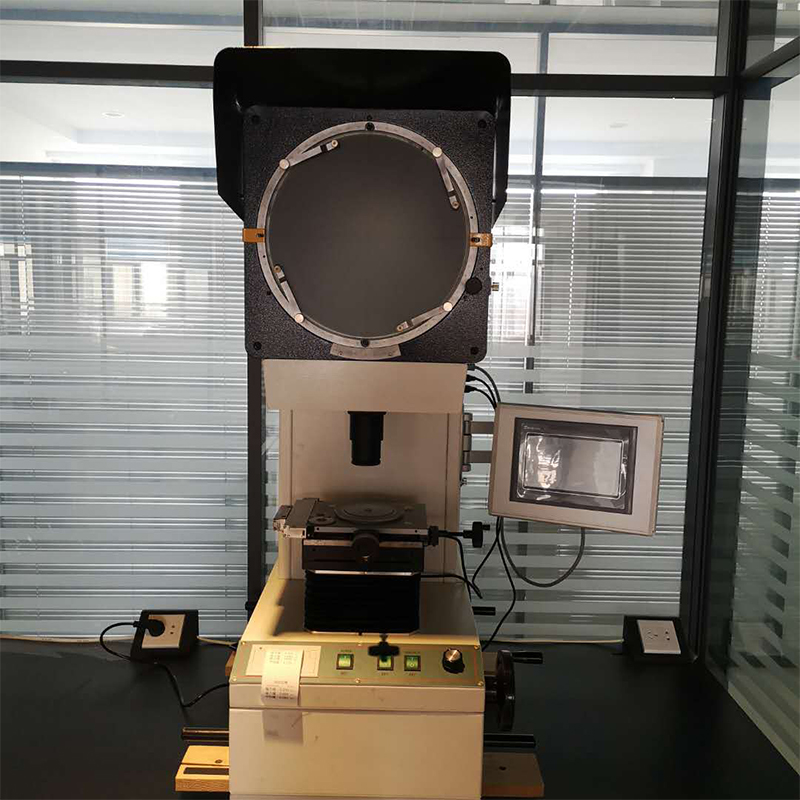

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy