Supplier of Power Frequency Spark Testing Machines for Quality Assurance Solutions

Understanding Power Frequency Spark Test Machines A Guide for Suppliers and Users

In the electrical testing industry, ensuring the reliability and safety of electrical equipment is paramount. Among the numerous testing methods employed, the power frequency spark test stands out as one of the most effective ways to assess the integrity of equipment insulation. This article will delve into the significance of power frequency spark test machines, the importance of selecting a reputable supplier, and key considerations for organizations looking to procure these essential testing devices.

What is Power Frequency Spark Testing?

Power frequency spark testing, also known as dielectric withstand testing or high-voltage testing, is a procedure used to evaluate the insulation quality of electrical components by applying a voltage that is significantly higher than the operating voltage. Typically set at the standard power frequency of 50 or 60 Hz, this test involves exposing electrical equipment to an alternating current (AC) voltage for a specific duration. The primary objective of this testing method is to identify any potential insulation failures that could lead to electrical breakdown, ultimately ensuring the safety and longevity of the apparatus.

The Significance of Power Frequency Spark Test Machines

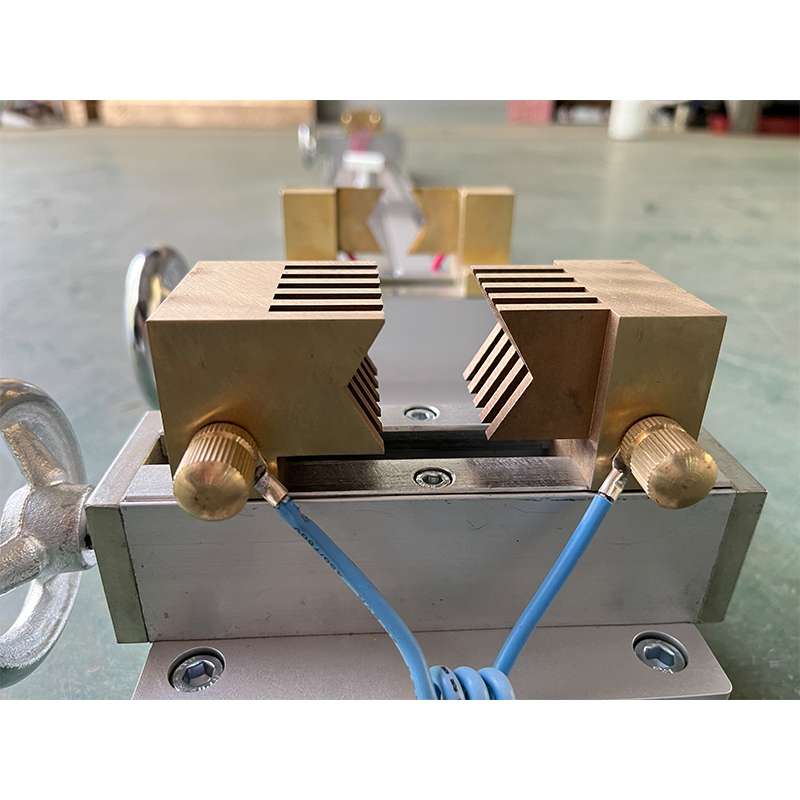

Power frequency spark test machines play a crucial role in various industries, including manufacturing, utilities, and construction. These machines are vital in testing electrical equipment such as transformers, switchgear, cables, and motors. By simulating extreme conditions that equipment may encounter in real-world operations, power frequency testing helps manufacturers detect weak insulation, contamination, moisture, or manufacturing defects before the products are deployed.

The successful execution of power frequency spark tests results in various tangible benefits. Firstly, it enhances safety by identifying vulnerabilities that could lead to electrical failures or fires. Secondly, it aids compliance with international safety standards and regulations, which is often a prerequisite for market access in different regions. Lastly, by ensuring that only high-quality products reach the market, manufacturers can build strong reputations and customer trust.

Selecting a Reliable Supplier

power frequency spark test machine supplier

When searching for a supplier of power frequency spark test machines, several factors should be taken into account

1. Experience and Reputation Choose suppliers that have a proven track record in the industry. Look for those who have been in the business for several years, as their experience often correlates with product quality and customer service.

2. Product Range A reputable supplier should offer a wide selection of test machines, catering to various needs and specifications. The ability to customize testing solutions according to specific requirements is a crucial factor that separates the best suppliers from the rest.

3. Technical Support and Service Consider suppliers that provide comprehensive technical support, including installation, maintenance, and training services. This support is vital in ensuring that operators can effectively use the testing machines and obtain accurate results.

4. Quality Standards Ensure the equipment provided meets international quality standards, such as ISO certifications. These certifications indicate that the products have undergone stringent testing and quality control processes.

5. User Reviews and Testimonials Research user experiences with potential suppliers. Honest feedback can provide insights into the reliability and performance of the machines, as well as the level of customer service provided.

Conclusion

In conclusion, power frequency spark test machines are essential tools in maintaining safety and quality standards in electrical equipment. Their capability to detect insulation weaknesses makes them invaluable across multiple sectors. When selecting a supplier for these machines, prioritize experience, product diversity, quality assurance, and robust support services. By making informed decisions, organizations can ensure they invest in high-quality testing solutions that protect both their interests and the safety of their end-users. Ultimately, a solid partnership with a reliable supplier will contribute to the success and reputation of any company operating in the electrical equipment sector.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy