Vertical Profile Projector Manufacturing Solutions for Precision Measurement and Inspection

Vertical Profile Projector Factory A Comprehensive Overview

In the modern manufacturing landscape, precision and accuracy are paramount. One of the key instruments that meet these needs is the vertical profile projector. This sophisticated device enables manufacturers to translate complex profiles into precise measurements, making it an invaluable tool in quality control and machining processes. In this article, we will explore the significance of vertical profile projectors, the manufacturing process involved in creating these devices, and the implications of their use in various industries.

Understanding Vertical Profile Projectors

A vertical profile projector, also known as a shadow graph or optical comparator, leverages optics to magnify the profile of a part, casting its shadow onto a graduated screen. This allows operators to compare the actual shape of a component with its design specifications. The device typically consists of a light source, a lens system, and a projection screen, which work in tandem to deliver high levels of accuracy and visibility.

The main purpose of a vertical profile projector is to enable quality control inspectors to measure the dimensions of machined parts quickly and reliably. By projecting the silhouette of a part onto a scale, users can easily see any deviations from the desired profile, thereby ensuring that each component meets stringent quality standards.

The Manufacturing Process

Creating a vertical profile projector requires a combination of high-precision engineering and sophisticated manufacturing processes. The following steps outline the typical production cycle for these devices

1. Designing the Optical System The heart of any profile projector is its optical system. Engineers meticulously design the lenses and light sources to ensure optimal magnification and clarity. Advanced computer-aided design (CAD) software is employed to simulate how light will interact with different materials.

2. Fabrication of Components Once the design is finalized, manufacturing begins. Components such as the projector body, lens, and screen are fabricated using high-grade materials. Precision machining processes, including CNC milling and turning, are utilized to achieve the exact specifications required.

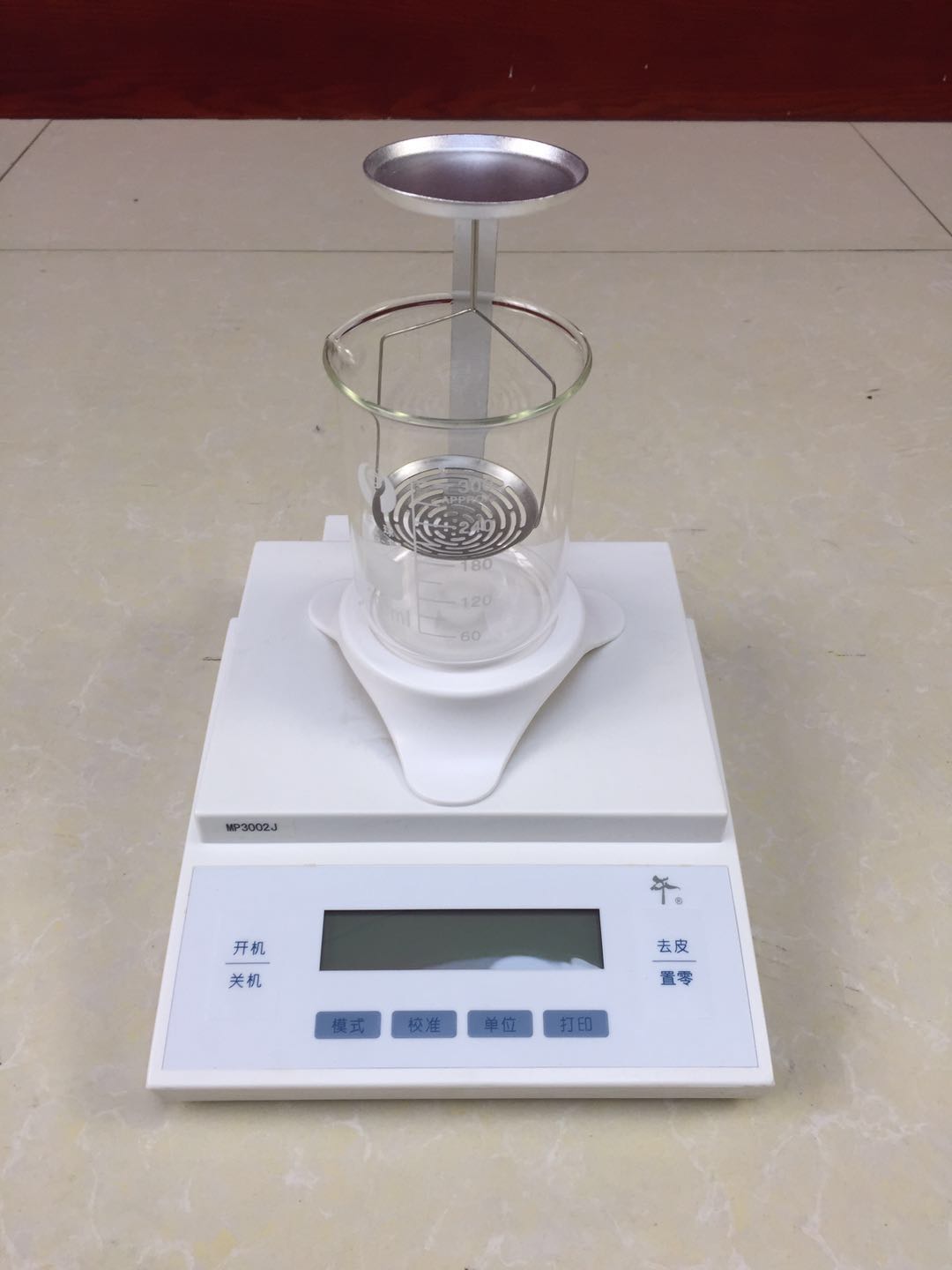

vertical profile projector factory

3. Assembly After individual components are produced, skilled technicians assemble them into a complete projector unit. This process requires meticulous attention to detail, as any misalignment can significantly affect the instrument's accuracy.

4. Calibration Calibration is crucial for ensuring that the vertical profile projector delivers precise measurements. This involves setting the projection system to industry standards and performing various tests to confirm accuracy. Frequent calibration sessions are vital to maintain the integrity of the device.

5. Quality Control Before leaving the factory, each vertical profile projector undergoes rigorous quality control checks. These inspections assess both the mechanical and optical performance of the device to ensure it meets the manufacturer's specifications.

Industry Applications

Vertical profile projectors are widely used across various industries. In manufacturing, they play a critical role in quality assurance processes, particularly in sectors like aerospace, automotive, and electronics, where precision is non-negotiable. They are essential for measuring gears, cams, and other intricate components, ensuring that they function correctly within larger assemblies.

In addition, these devices are invaluable in research and development settings, where engineers rely on them to visualize and refine complex shapes and profiles. The automotive industry, for example, uses profile projectors to analyze the geometric tolerances of parts before they are put into production.

Conclusion

The vertical profile projector represents a fusion of traditional craftsmanship and modern technology, embodying the precision required in today’s manufacturing environments. As industries continue to evolve, the reliance on such instruments for quality control and measurement will undoubtedly increase. Manufacturers invested in creating and maintaining high-quality vertical profile projectors will position themselves at the forefront of efficiency and accuracy, equipping them for the challenges of an ever-competitive landscape. As we look to the future, embracing innovation in measurement technologies will be critical for sustaining growth and delivering exceptional products.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy