Ene . 26, 2025 03:54

Back to list

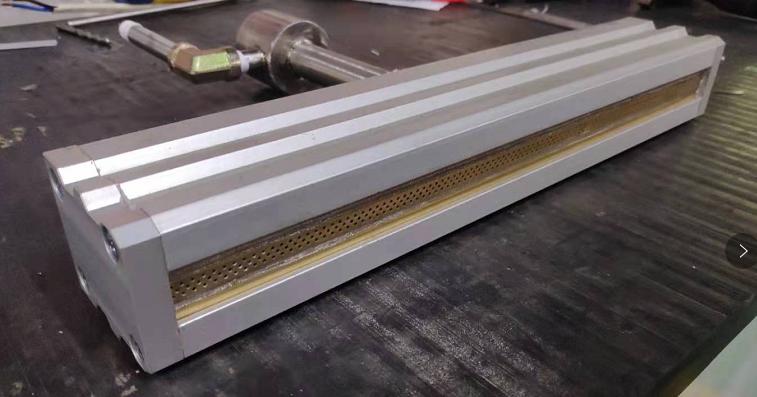

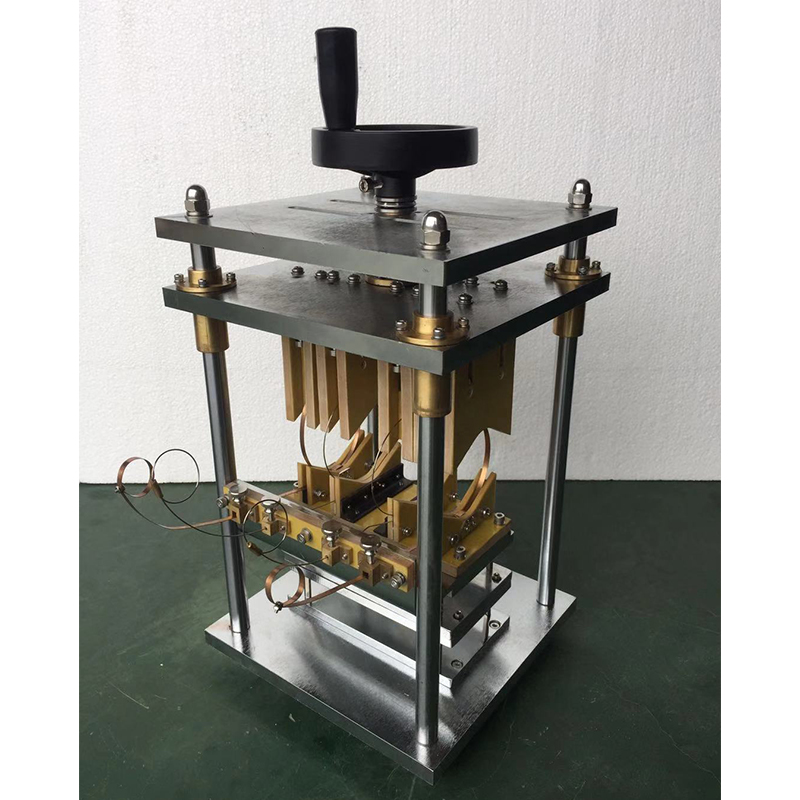

custom cable insulation slicing machine

Investing in a custom cable insulation slicing machine can mark a transformative step for any enterprise involved in cable manufacturing or processing. Here, we delve into the multifaceted benefits of these advanced machines, drawing from years of industry experience and understanding the expertise required in handling sophisticated equipment, ensuring top performance and reliability.

The authoritativeness of a custom cable insulation slicing machine is established through its advanced technological integration. Featuring state-of-the-art control systems, these machines offer real-time monitoring and adjustments, facilitating immediate corrections and maintaining process stability. This automation capability not only ensures a higher quality product but also frees up skilled technicians to focus on other critical areas of production, thus optimizing workflow and maximizing human resources. Trustworthiness in production is bolstered by the adoption of these machines, as they significantly reduce the likelihood of human error — a common pitfall in manual slicing techniques. In industries where safety and reliability are non-negotiable, ensuring the integrity of cable insulation through precise slicing methods is crucial. Custom machines, equipped with sensors and feedback systems, can automatically detect and correct deviations, thus maintaining the stringent standards expected by today's safety regulations. Moreover, the introduction of custom cable insulation slicing machines can enhance operational competitiveness. Businesses that leverage these machines can offer more diverse and innovative product lines due to the flexibility these machines provide. The ability to handle various insulation materials and sizes with ease allows companies to cater to a wider range of client needs, thus expanding market reach and driving growth. In conclusion, for businesses focused on quality, efficiency, and innovation in cable production, investing in custom cable insulation slicing machines represents a significant advancement. The blend of real-world application experience, technical expertise, authoritative technological capabilities, and an assured level of trustworthiness distinguishes these machines in the market. By ensuring consistently high-quality outcomes and reducing operational inefficiencies, they equip businesses with the tools necessary to thrive in an increasingly competitive landscape. When evaluating the long-term benefits, the decision to adopt such technology is not just a purchase—it is a strategic investment in the future of your company's manufacturing and production capabilities.

The authoritativeness of a custom cable insulation slicing machine is established through its advanced technological integration. Featuring state-of-the-art control systems, these machines offer real-time monitoring and adjustments, facilitating immediate corrections and maintaining process stability. This automation capability not only ensures a higher quality product but also frees up skilled technicians to focus on other critical areas of production, thus optimizing workflow and maximizing human resources. Trustworthiness in production is bolstered by the adoption of these machines, as they significantly reduce the likelihood of human error — a common pitfall in manual slicing techniques. In industries where safety and reliability are non-negotiable, ensuring the integrity of cable insulation through precise slicing methods is crucial. Custom machines, equipped with sensors and feedback systems, can automatically detect and correct deviations, thus maintaining the stringent standards expected by today's safety regulations. Moreover, the introduction of custom cable insulation slicing machines can enhance operational competitiveness. Businesses that leverage these machines can offer more diverse and innovative product lines due to the flexibility these machines provide. The ability to handle various insulation materials and sizes with ease allows companies to cater to a wider range of client needs, thus expanding market reach and driving growth. In conclusion, for businesses focused on quality, efficiency, and innovation in cable production, investing in custom cable insulation slicing machines represents a significant advancement. The blend of real-world application experience, technical expertise, authoritative technological capabilities, and an assured level of trustworthiness distinguishes these machines in the market. By ensuring consistently high-quality outcomes and reducing operational inefficiencies, they equip businesses with the tools necessary to thrive in an increasingly competitive landscape. When evaluating the long-term benefits, the decision to adopt such technology is not just a purchase—it is a strategic investment in the future of your company's manufacturing and production capabilities.

Latest news

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy