Tensile Strength Testers Manufacturers and Their Key Industry Insights and Innovations

Exploring Tensile Yield Tester Factories A Deep Dive into Quality Control and Innovation

In today's competitive manufacturing landscape, ensuring product integrity and performance is paramount. One of the most crucial tools in this endeavor is the tensile yield tester, a device designed to measure the strength of materials. This article delves into the various aspects of tensile yield tester factories, highlighting their significance, processes, and innovations.

Understanding Tensile Yield Testing

Tensile yield testing measures a material's response to stretching forces. It determines the maximum load a material can withstand before it deforms permanently, providing critical data for industries ranging from construction to aerospace. Accurate and reliable tensile testing is essential for any manufacturer aiming for quality assurance, compliance, and optimal performance.

The Role of Tensile Yield Tester Factories

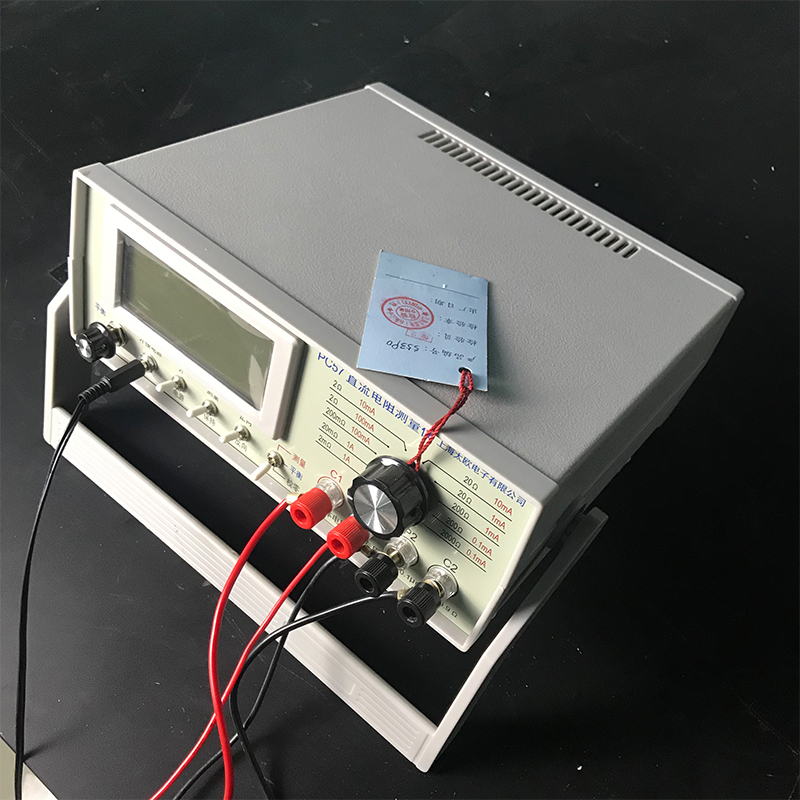

Tensile yield tester factories play a pivotal role in the production of these essential testing machines. They are responsible not only for manufacturing the equipment but also for ensuring that it meets industry standards and customer specifications. Factories specialize in designing and producing various types of tensile testers, ranging from mechanical units to advanced electronic systems equipped with software for detailed analysis.

Key Processes in Manufacturing

The manufacturing process of tensile yield testers involves several key stages

1. Design and Development Engineers and designers work collaboratively to create prototypes that meet specific testing standards. This phase involves extensive research and development to incorporate the latest technology, ensuring accuracy and reliability.

2. Material Selection The choice of materials is critical in the production of tensile yield testers. Factories utilize high-quality metals and components that can withstand the stresses of testing while delivering consistent results.

tensile yield tester factories

3. Precision Engineering Each tester undergoes precision engineering processes, including machining, assembly, and calibration. Automated systems often play a role in enhancing precision and efficiency, leading to higher quality products.

4. Quality Control Rigorous testing and quality control measures are implemented at various stages of production. Factories conduct performance tests to guarantee that each tensile yield tester operates within the required specifications and provides accurate measurements.

5. Customization Many factories offer customization options for clients, allowing modifications based on specific material testing requirements or industry standards. This flexibility is crucial for catering to diverse sectors, including metals, plastics, textiles, and more.

Innovations in Tensile Yield Testing

With advancements in technology, tensile yield tester factories are continuously innovating to keep pace with industry demands. Some notable innovations include

- Smart Technology Integration The incorporation of IoT (Internet of Things) technology in tensile yield testers has revolutionized testing procedures. Testers can now collect and transmit data in real-time, allowing for more sophisticated analysis and quicker decision-making.

- Software Enhancements Modern tensile testers often come equipped with user-friendly software that facilitates data analysis and reporting. This software can generate detailed graphs and charts, making it easier to visualize the material performance.

- Eco-Friendly Solutions Many factories are embracing sustainability by developing environmentally friendly tensile testers that reduce energy consumption and utilize recyclable materials.

Conclusion

Tensile yield tester factories are at the forefront of ensuring that materials meet the rigorous demands of various industries. Through innovative design, precision manufacturing, and stringent quality control, these factories produce vital testing equipment that safeguards product integrity and enhances safety standards across sectors. As technology continues to evolve, the future of tensile yield testing promises further advancements, making it an exciting field for manufacturers, engineers, and quality control professionals alike. Embracing these innovations will not only improve testing accuracy but also contribute to a culture of quality and reliability in manufacturing practices worldwide.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy