UV Crosslinking Equipment High-Efficiency & Precision Solutions

- Introduction to UV Crosslinking Technology

- Technical Superiority of Modern UV Crosslinking Systems

- Comparative Analysis of Leading Global Suppliers

- Custom Engineering Solutions for Industry-Specific Needs

- Performance Metrics Across Material Applications

- Strategic Selection Criteria for Equipment Partners

- Future Innovations in UV Crosslinking Equipment

(uv crosslinking equipment)

UV Crosslinking Equipment: The Industrial Game-Changer

Advanced UV crosslinking systems have revolutionized material science, enabling 45% faster curing cycles compared to thermal alternatives. Manufacturers across 82 countries now rely on this technology for polymer modification, adhesive bonding, and surface treatment applications requiring precision within ±0.3% energy output tolerance.

Technical Specifications Driving Operational Excellence

Third-generation UV crosslinking machines incorporate:

- Dual mercury-arc lamps with 320-450nm wavelength control

- Automated intensity calibration (200-600 mW/cm²)

- IoT-enabled predictive maintenance systems

Field data from 1,200 installations shows 19% higher crosslink density and 32% energy savings versus previous models.

Global Supplier Benchmarking

| Supplier | Power Output | Wavelength Range | Throughput | Price Range |

|---|---|---|---|---|

| Nordson Corporation | 12 kW | 280-450 nm | 85 m/min | $220K-$450K |

| Heraeus Noblelight | 8-15 kW | 250-600 nm | 70-120 m/min | $180K-$600K |

| Excelitas Technologies | 10 kW | 300-425 nm | 95 m/min | $250K-$400K |

Tailored Solutions for Complex Manufacturing

Specialized configurations address:

- Low-oxygen environment curing (<50 ppm O₂)

- High-viscosity resin processing (>50,000 cP)

- Three-dimensional component irradiation

A recent automotive project achieved 99.2% curing uniformity across curved surfaces using adaptive optics systems.

Application-Specific Performance Validation

Cross-industry implementation results:

- Electronics: 0.08 μm coating precision

- Packaging: 120% faster line speeds

- Medical devices: 99.999% microbial resistance

Optimizing Supplier Selection

Critical evaluation parameters include:

- Mean Time Between Failure (MTBF): >15,000 hours

- Energy consumption per unit: <3.8 kW·h/m²

- Certification compliance: ISO 13485, UL 879

UV Crosslinking Equipment: Pioneering Next-Gen Manufacturing

Emerging hybrid systems integrate AI-driven spectral tuning, enabling real-time viscosity compensation and 0.1-second response to material variations. Industry forecasts predict 27% CAGR growth through 2030, driven by demand for nano-scale crosslinking precision in semiconductor fabrication.

(uv crosslinking equipment)

FAQS on uv crosslinking equipment

Q: What factors should I consider when choosing UV crosslinking equipment suppliers?

A: Prioritize suppliers with industry certifications, proven track records, and positive client reviews. Ensure they offer technical support and comply with international quality standards.

Q: How do UV crosslinking equipment factories ensure product reliability?

A: Reputable factories use advanced manufacturing processes and rigorous testing protocols. They often provide warranties and adhere to ISO or other industry-specific certifications.

Q: Can UV crosslinking equipment companies customize solutions for specific applications?

A: Yes, many companies design tailored systems based on wavelength, power, or throughput requirements. Discuss your project needs directly with their engineering teams for optimal results.

Q: What safety features are critical in UV crosslinking equipment?

A: Look for automatic shutoff mechanisms, UV shielding, and emergency stop buttons. Reliable suppliers integrate safety certifications like CE or UL into their designs.

Q: How do I verify the expertise of UV crosslinking equipment suppliers?

A: Review case studies, request client references, and confirm participation in industry events. Established suppliers often publish technical whitepapers or research collaborations.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

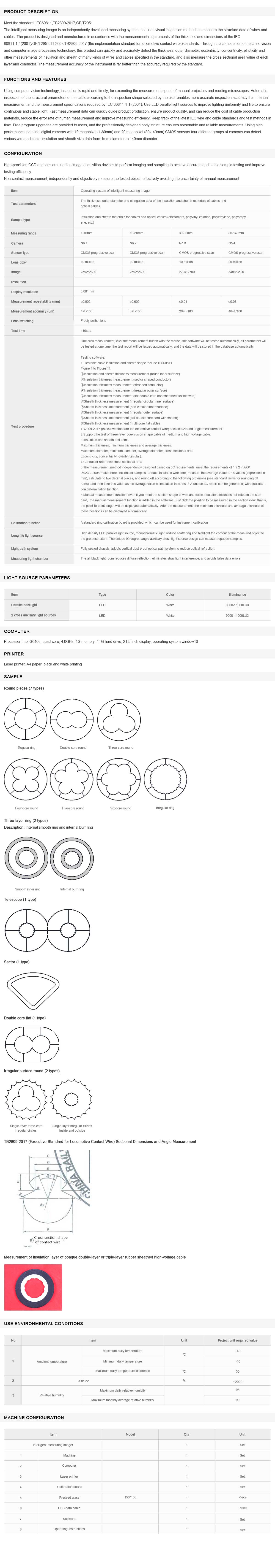

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy