Reliable Cable Burn Testing Equipment from Leading Manufacturers for Optimal Performance and Safety

The Evolution of Cable Burning Testers A Manufacturer's Perspective

In the world of electrical engineering, safety and reliability are paramount. For manufacturers of cables and electrical components, ensuring that their products can withstand extreme conditions is an essential part of the production process. This is where cable burning testers come into play. Over the years, these devices have evolved significantly, and their importance in the testing and quality assurance of electrical materials cannot be overstated.

Understanding Cable Burning Testers

Cable burning testers are specialized instruments designed to assess the fire-resistance of various types of cables. They simulate extreme thermal conditions, determining how a cable reacts when exposed to high temperatures and flames. The primary goal of these tests is to evaluate a cable's ability to limit the spread of fire, minimize smoke production, and emit hazardous gases when burned. Such testing is crucial not only for compliance with safety standards but also for ensuring the longevity and reliability of electrical systems in real-world applications.

Importance of Quality Assurance

For manufacturers, investing in reliable cable burning testers is integral to quality assurance practices. Regulations and standards established by organizations such as the International Electrotechnical Commission (IEC) and Underwriters Laboratories (UL) mandate rigorous testing to ensure that electrical products meet safety requirements. Non-compliance can lead to catastrophic failures, resulting in significant financial losses, liability issues, and, worst of all, endangering lives.

Thus, cable burning testers are not merely tools; they are essential components of a comprehensive quality management system

. By investing in state-of-the-art testing equipment, manufacturers can better guarantee that their products are safe for consumer use.Advancements in Testing Technology

cable burning tester manufacturer

The evolution of cable burning testers reflects the overall advancements in technology. Older models often relied on manual operation and basic measurement techniques, which made the testing process time-consuming and prone to human error. However, the newer generation of cable burning testers features automated systems that can conduct tests with precision and efficiency. These modern devices come equipped with sophisticated monitoring systems that can offer real-time data, enabling manufacturers to make informed decisions quickly.

Additionally, advancements in materials and design have led to testers that can accommodate various cable types, from low-voltage communication wires to high-voltage power conductors. The versatility of modern cable burning testers allows manufacturers to conduct comprehensive testing on a range of products, thereby enhancing their research and development capabilities.

The Role of Manufacturers in Market Development

As a manufacturer of cable burning testers, it is essential to stay ahead of the curve by continuously innovating and updating product offerings. This involves investing in research and development to explore new testing methodologies and improve existing technologies. Collaborating with standard-setting organizations can also provide insights into emerging requirements and trends in the industry.

Manufacturers must also take feedback from customers into account, using it to refine their products and services. High-quality customer support is crucial, as it ensures that clients can maximize the potential of their testing equipment and achieve accurate, reliable results.

Conclusion

In conclusion, cable burning testers are indispensable tools for manufacturers involved in electrical cable production. They play a critical role in ensuring safety and compliance with industry standards. As technology advances, these testers continue to evolve, becoming more sophisticated and capable. Manufacturers who recognize the importance of these devices and invest in them strategically will not only enhance their product quality but also ensure the safety and satisfaction of their end-users. In the ever-competitive field of electrical engineering, having reliable testing equipment can make all the difference, safeguarding both lives and investments.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

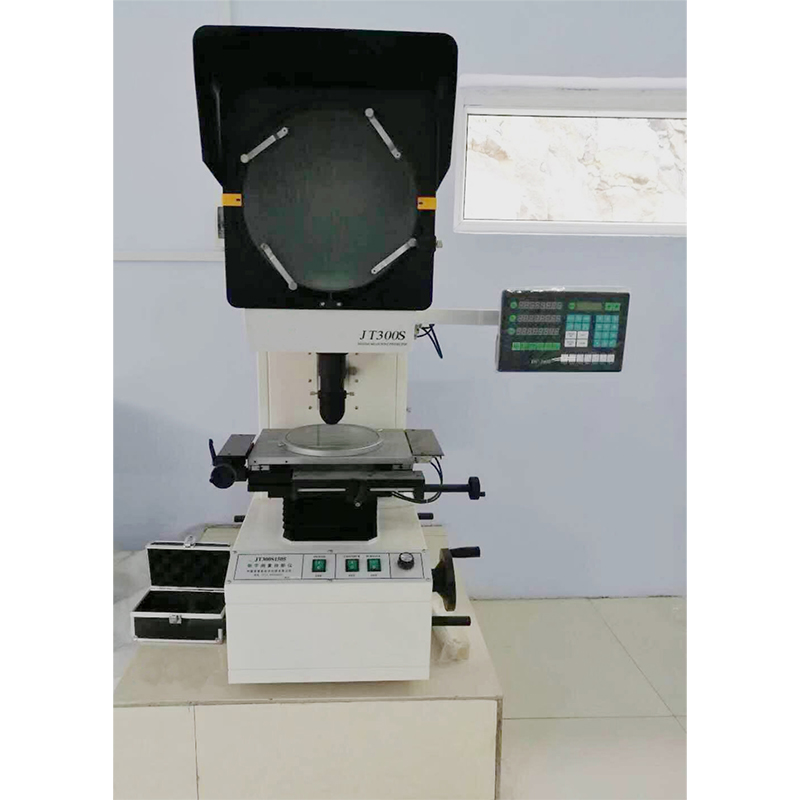

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy