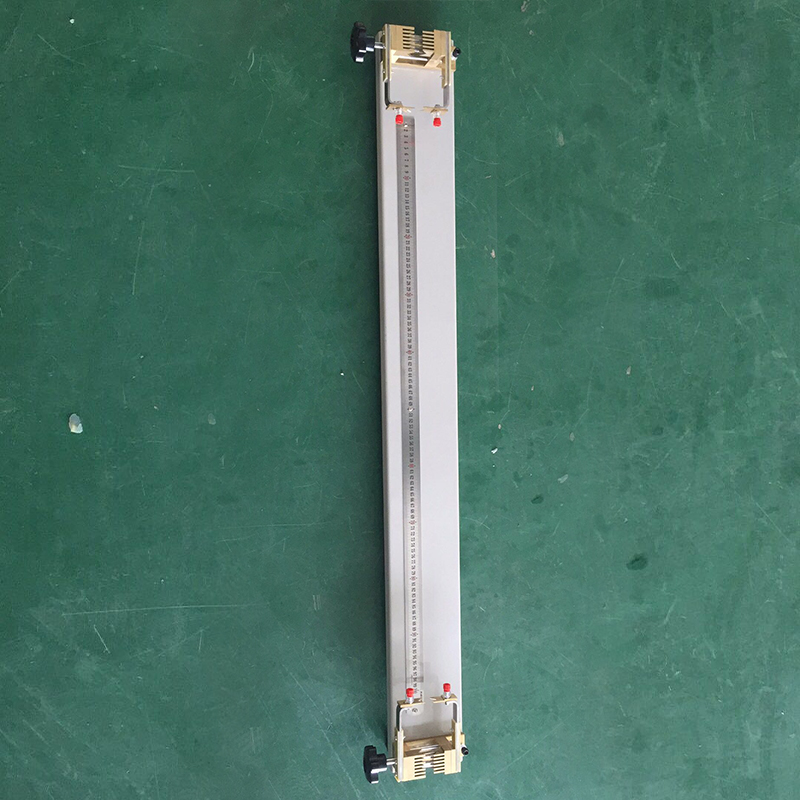

custom low resistance tester

Custom Low Resistance Tester The Key to Precision in Electrical Measurements

In today's fast-paced technological environment, precision and reliability in electrical measurements have become paramount for various industries. Among the essential tools used for this purpose is the low resistance tester. Custom low resistance testers offer tailored solutions, enhancing the efficiency and accuracy of resistance measurements. This article will explore the significance, applications, and features of custom low resistance testers.

Understanding Low Resistance Testing

Low resistance testing is crucial in electrical and electronic applications where the resistance values are typically very low, often measured in micro-ohms. These measurements are critical in determining the quality and performance of electrical connections, such as those found in circuit breakers, bus bars, and connectors. High resistance in connections can lead to overheating, increased energy consumption, and ultimately, equipment failure. Thus, accurate measurement of low resistance is essential for ensuring efficient operation and safety.

The Need for Customization

While standard low resistance testers are effective, they may not meet the specific requirements of every application. Custom low resistance testers are designed to cater to unique client specifications, incorporating specialized features that address particular measurement needs. Customization can include adjustments in test current, measurement range, precision levels, and user interfaces. This adaptability ensures that industries such as manufacturing, automotive, aerospace, and telecommunications can achieve accurate and reliable results that align with their operational requirements.

Key Features of Custom Low Resistance Testers

1. Tailored Measurement Ranges Custom testers can offer a broader range of resistance measurements, allowing users to select the most appropriate scale for their applications. This flexibility is crucial in industries where different components require varying levels of precision.

2. Adjustable Test Currents Depending on the material and application, the test current can be calibrated to prevent damage to sensitive components. Custom testers provide the ability to adjust the test current to match the specific resistance measurement requirements.

3. Enhanced Accuracy and Precision Many industrial applications demand precise measurements to avoid false readings that can result in costly downtime or equipment failure. Custom low resistance testers can feature advanced measurement technology, such as four-wire sensing, to enhance accuracy and eliminate errors caused by lead and contact resistances.

custom low resistance tester

4. User-Friendly Interfaces With varying levels of technical expertise in different industries, custom testers can be designed with intuitive displays and controls. This ease of use reduces the learning curve and increases efficiency during testing procedures.

5. Robust Build Quality Custom low resistance testers can be built to endure harsh industrial environments. Rugged casings, dust-proof, and water-resistant features ensure longevity and reliability in diverse settings.

6. Data Logging and Connectivity In an era of digital transformation, the ability to log data and connect to other devices is invaluable. Custom low resistance testers can be equipped with data recording capabilities and interfaces for integration with computer software for further analysis and reporting.

Applications of Custom Low Resistance Testers

- Manufacturing In the manufacturing sector, ensuring the integrity of joints and connections can prevent product defects and recalls. Custom testers allow for in-line testing during production processes.

- Telecommunications For telecommunications infrastructure, low resistance measurements are critical for ensuring signal integrity and preventing interference in communications.

- Automotive Industry In automotive manufacturing, the electrical systems must operate without faults. Custom testers can ensure that components like battery terminals and connectors maintain optimal performance.

- Aerospace The aerospace industry demands the highest standards of safety and reliability. Custom testers help ensure that all electrical connections meet stringent regulatory requirements.

Conclusion

Custom low resistance testers play a vital role in ensuring the efficiency, reliability, and safety of electrical systems across various industries. By providing tailored solutions that meet the specific needs of different applications, these testers contribute significantly to the advancement of technology and the reliability of electrical connections. Adopting custom low resistance testing equipment is a proactive step toward enhancing quality control and operational efficiency in any organization handling electrical components.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy