digital profile projectors company

The Rise of Digital Profile Projectors Revolutionizing Precision Measurement

In the realm of engineering and manufacturing, precision measurement is paramount. As industries lean towards automation and sophisticated technology, digital profile projectors have emerged as indispensable tools for ensuring accuracy during the production process. This article explores the evolution, benefits, and applications of digital profile projectors, highlighting their pivotal role in modern manufacturing.

Understanding Digital Profile Projectors

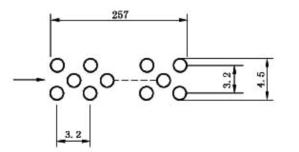

A digital profile projector, often referred to as an optical comparator, projects the silhouette of an object onto a screen. This projection allows operators to analyze and measure the dimensions, shapes, and features of the component with remarkable accuracy. Unlike traditional mechanical measuring tools, digital profile projectors utilize advanced optical systems and digital technology, making them more efficient and user-friendly.

The Evolution of Measuring Technology

The origins of profile projectors date back to the early 20th century when they were first introduced as optical measurement devices. However, it wasn't until the incorporation of digital technologies that these devices transformed into highly accurate and versatile machines. The inevitable integration of computer-aided design (CAD) systems and digital imaging further propelled the development of digital profile projectors, making them essential in various manufacturing processes.

Advantages of Digital Profile Projectors

The transition from traditional to digital profile projectors offers several notable advantages

1. Enhanced Accuracy Digital systems minimize human error in measurements, ensuring higher precision in the evaluation of parts.

2. User-Friendly Interfaces Modern digital profile projectors come with intuitive software and interfaces, allowing operators to perform complex measurements with just a few clicks.

digital profile projectors company

4. Versatility Digital profile projectors can be used across various industries, including automotive, aerospace, electronics, and medical device manufacturing.

5. Improved Efficiency The combination of fast data processing and automated measurement can significantly reduce inspection times, allowing for more rapid production cycles.

Applications Across Industries

Digital profile projectors have found their place in numerous sectors due to their remarkable adaptability. In manufacturing, they are used for

- Quality Control Ensuring that manufactured components meet the specified tolerances and dimensions, preventing defects before products reach customers.

- Tool and Die Making Assisting in the inspection and measurement of molds and tooling to maintain precision throughout the production process.

- Component Measurement Used extensively in industries where intricate parts are common, such as electronics and medical devices, to guarantee that every component meets stringent specifications.

- Research and Development Engineers and designers utilize these projectors during the prototyping phase to measure and refine designs for optimal performance.

Conclusion

As industries continue to evolve and demand higher precision and efficiency, digital profile projectors stand out as a critical component in manufacturing and quality assurance. Their technological advancements enable companies to maintain competitiveness in a rapidly changing market landscape. By embracing these innovative tools, businesses can streamline their operations, reduce costs, and ensure the delivery of superior products. With the ongoing advancements in optical technology and data processing, the future of digital profile projectors promises even greater capabilities, ensuring their role in precision measurement will only expand.

In summary, the digital profile projector is a testament to how technology can transform traditional processes into streamlined, high-accuracy operations. As the manufacturing landscape becomes increasingly complex, the demand for tools that offer both precision and efficiency will rise, making digital profile projectors an essential investment for any forward-thinking company.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy