Top Manufacturers of Semi-Conductive Test Fixtures for Enhanced Performance and Accuracy

The Rise of Semi-Conductive Test Fixture Manufacturers Ensuring Quality and Precision in Electronics Testing

In today’s rapidly evolving technological landscape, the need for reliable and precise electronic components has never been greater. Among the critical components in the testing and manufacturing of these devices are semi-conductive test fixtures. These fixtures serve as essential tools that ensure the accuracy and efficiency of electronic tests. As the electronics industry continues to expand, the role of semi-conductive test fixture manufacturers has become increasingly pivotal.

Understanding Semi-Conductive Test Fixtures

Semi-conductive test fixtures are specialized equipment designed to hold, support, and connect semiconductor devices during testing processes. They facilitate a range of tests, including electrical, thermal, and mechanical evaluations. The primary purpose of these fixtures is to create a secure interface between the testing equipment and the semiconductor device, ensuring consistent and repeatable results.

Typically made from materials that can withstand various temperatures and provide adequate insulation, these fixtures come in various designs tailored to the specific needs of different devices. As the demand for compact and efficient electronic devices grows, so does the complexity of test fixtures, pushing manufacturers to innovate continuously.

The Importance of Quality and Precision

In the realm of electronics, any error in testing can lead to significant consequences, including device failures, financial losses, and reputational damage. Thus, the quality and precision of semi-conductive test fixtures are paramount. Manufacturers are increasingly investing in advanced technologies such as automated assembly systems, CNC machining, and 3D printing to enhance the accuracy and durability of their products.

Moreover, the need for stringent compliance with industry standards cannot be overstated. Regulatory authorities often mandate specific testing protocols that companies must adhere to, and semi-conductive test fixture manufacturers must ensure that their products meet these exacting requirements. This commitment to quality not only enhances the reliability of the testing process but also fosters trust between manufacturers and their clients.

Market Trends and Innovations

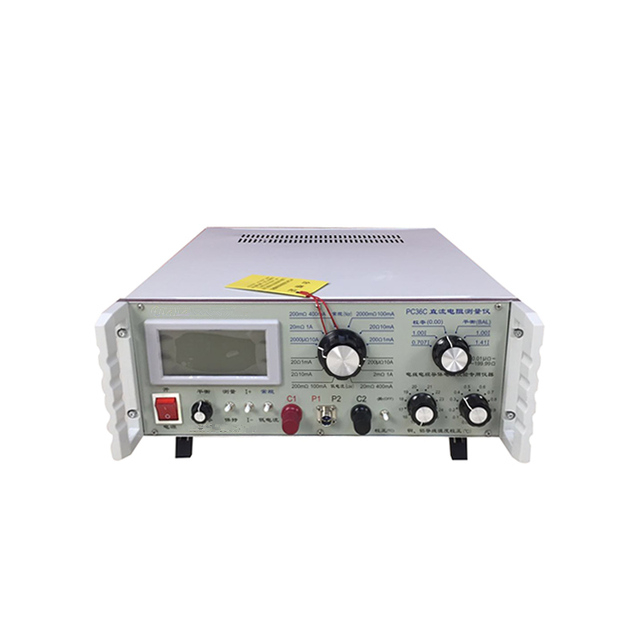

semi-conductive test fixture manufacturers

The market for semi-conductive test fixture manufacturers is experiencing steady growth, driven by the proliferation of smart devices, automotive electronics, and IoT applications. As these sectors expand, manufacturers are challenged to create fixtures that accommodate an increasingly diverse range of semiconductor devices.

One notable trend is the integration of smart technologies into test fixtures. Manufacturers are now developing fixtures equipped with IoT capabilities, enabling real-time data collection and analysis during tests. This innovation allows for immediate feedback and adjustments, significantly improving the testing process's efficiency and effectiveness.

Additionally, there is a growing emphasis on modular test fixtures, which offer flexibility in testing different devices. Modular designs allow manufacturers to adapt and reconfigure fixtures easily, reducing the time and cost associated with developing new testing setups.

Challenges Facing Manufacturers

Despite the promising market trends, semi-conductive test fixture manufacturers face several challenges. The rapid pace of technological advancement requires these manufacturers to stay ahead of the curve, continuously updating their designs and methodologies. Moreover, the increasing complexity of semiconductor devices necessitates bespoke solutions, which can drive up production costs and lead times.

Supply chain disruptions, as highlighted during recent global events, also pose a significant challenge. Manufacturers must navigate fluctuating material costs and availability, often impacting the final price and delivery of their products. Building resilient supply chains and fostering strong relationships with suppliers are essential strategies to mitigate these risks.

Conclusion

Semi-conductive test fixture manufacturers play a crucial role in the electronics industry, ensuring the quality and reliability of semiconductor devices. As technology continues to advance, these manufacturers are poised to innovate and adapt to meet the evolving needs of the market. By prioritizing quality, embracing new technologies, and overcoming industry challenges, they will not only contribute to the success of their clients but also drive the future of electronics testing forward. As the industry progresses, the partnership between manufacturers and their clients will be more vital than ever in fostering a new era of precision and efficiency in electronic testing.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy