jaan. . 11, 2025 10:40

Back to list

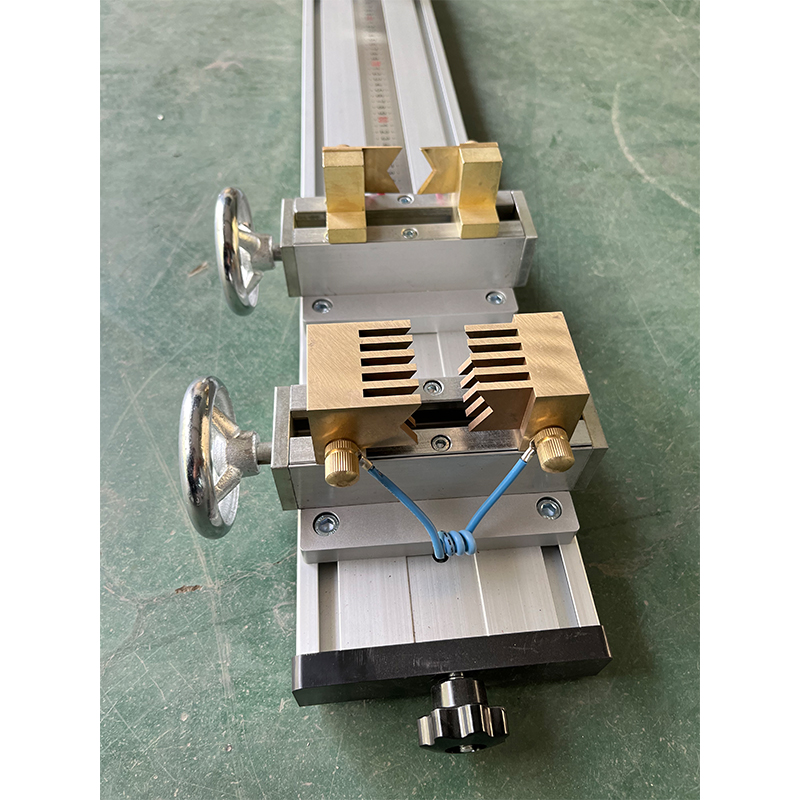

tensile tester

The realm of material testing is vast and nuanced, and at the heart of understanding a material's mechanical properties lies the tensile tester. As a pivotal instrument in the evaluation of tensile strength, it provides critical insights that translate into real-world applications across numerous industries including automotive, construction, aerospace, and consumer goods.

Moreover, trustworthiness in tensile testing is paramount. Calibration and maintenance are routinely conducted on our equipment to ensure accuracy. Every measurement taken can be traced back to standardized methods, reinforcing the reliability of the data. Clients rely on our results for substantial investment and design decisions, necessitating an unwavering commitment to precision and integrity. For anyone involved in product development or quality assurance, integrating tensile testers into your testing regimen is indispensable. The wealth of information derived from these tests not only optimizes material utilization but also enhances product durability and functionality, paving the way for innovations that stand the test of time. Understanding and leveraging the insights provided by tensile testers ensures that your materials meet stringent specifications and exceed expectations. As technology advances, so too does the sophistication of tensile testing, but at its core remains a fundamental commitment to uncovering the truths about material strength and endurance. Embrace the expertise and authority behind tensile testing, and empower your enterprise with data that drives innovation and assures quality beyond doubt.

Moreover, trustworthiness in tensile testing is paramount. Calibration and maintenance are routinely conducted on our equipment to ensure accuracy. Every measurement taken can be traced back to standardized methods, reinforcing the reliability of the data. Clients rely on our results for substantial investment and design decisions, necessitating an unwavering commitment to precision and integrity. For anyone involved in product development or quality assurance, integrating tensile testers into your testing regimen is indispensable. The wealth of information derived from these tests not only optimizes material utilization but also enhances product durability and functionality, paving the way for innovations that stand the test of time. Understanding and leveraging the insights provided by tensile testers ensures that your materials meet stringent specifications and exceed expectations. As technology advances, so too does the sophistication of tensile testing, but at its core remains a fundamental commitment to uncovering the truths about material strength and endurance. Embrace the expertise and authority behind tensile testing, and empower your enterprise with data that drives innovation and assures quality beyond doubt.

Latest news

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy