China Cable Thermal Elongation Testing Methods and Standards Overview

Thermal Elongation Testing of Cables in China Significance and Methodology

Cable technology plays a critical role in a wide range of industries, from construction and infrastructure to telecommunications and transportation. A vital aspect of cable performance is its behavior under varying temperature conditions. In this regard, the thermal elongation test is a crucial procedure used to evaluate how cables respond to thermal stress. This article delves into the significance, methodologies, and implications of thermal elongation testing of cables in China.

Understanding Thermal Elongation

Thermal elongation refers to the expansion of materials when exposed to heat. Different materials expand at different rates, and understanding this behavior is crucial for applications where cables face significant temperature fluctuations. For cables, excessive thermal elongation can lead to several issues, including mechanical stress, insulation damage, and electrical conduction problems, potentially leading to system failures. Therefore, the thermal elongation test provides essential data on a cable's performance and durability under thermal stress.

Why Thermal Elongation Testing Matters

In China, the rapid pace of industrialization and urbanization has increased the demand for reliable and efficient cable systems. High-performance cables are essential in industries such as energy, telecommunications, and public infrastructure. The consequences of cable failure due to thermal elongation can be severe, causing not only economic losses but also safety hazards.

Furthermore, with China's diverse climate, cables must endure a wide range of temperatures, making thermal elongation testing even more pertinent. Conducting these tests ensures that cables maintain their integrity and function effectively under both extreme heat and cold conditions. Regulatory standards in China increasingly require manufacturers to conduct such testing to ensure compliance and reliability.

Methodology of Thermal Elongation Testing

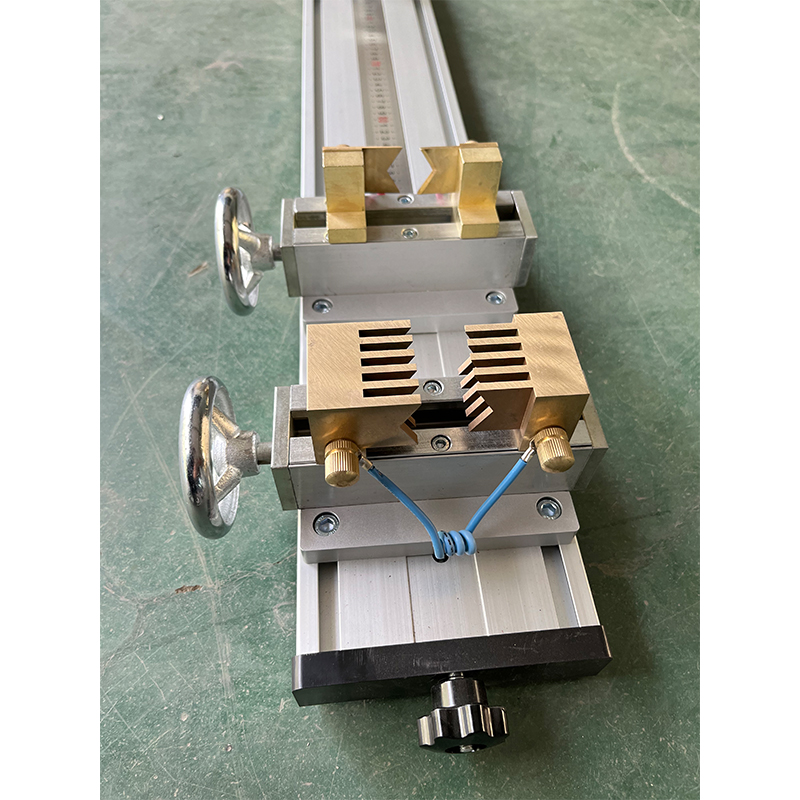

china cable thermal elongation test

The thermal elongation test involves several steps to accurately assess the elongation properties of cable materials. The following sections outline the typical components of the testing process

1. Sample Preparation The first step involves selecting representative samples of cable materials, including insulation and conductor components. Samples should be cut to a standard length for uniform testing.

2. Temperature Control The test requires precise temperature control. The samples are usually placed in an environmental chamber, which can simulate various temperature conditions. Testing typically occurs over a range of temperatures, often from -40°C to +90°C, depending on the specific application of the cables.

3. Monitoring Elongation As the temperature is altered, the elongation of the cable samples is measured. Digital extensometers or advanced imaging technology can be used to monitor the degree of elongation accurately over time. Measurements are taken at predetermined temperature intervals to create a comprehensive data set.

4. Analysis of Data After testing, the collected data is analyzed to determine the thermal elongation coefficients and other relevant metrics. This analysis helps in understanding how much the material expands per degree of temperature change and whether the values fall within acceptable limits.

5. Report Generation Finally, a detailed report of the findings is prepared, which often includes comparisons against industry standards and recommendations for use in specific applications. This documentation assists manufacturers in product development and quality assurance processes.

Conclusion

As China continues to advance technologically and economically, the need for robust and resilient cable systems becomes increasingly vital. The thermal elongation test enables manufacturers to ensure that their cables can withstand the thermal stresses encountered in various environments. By adhering to rigorous testing standards, companies can improve the safety and reliability of their products while contributing to the overall stability of essential infrastructure. As this sector evolves, ongoing research and development in cable materials will likely lead to even more sophisticated testing methodologies, furthering the goal of creating safer and more efficient electrical systems.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy