coaxial cable slicer factory

Coaxial Cable Slicer Factory Precision and Efficiency in Cable Manufacturing

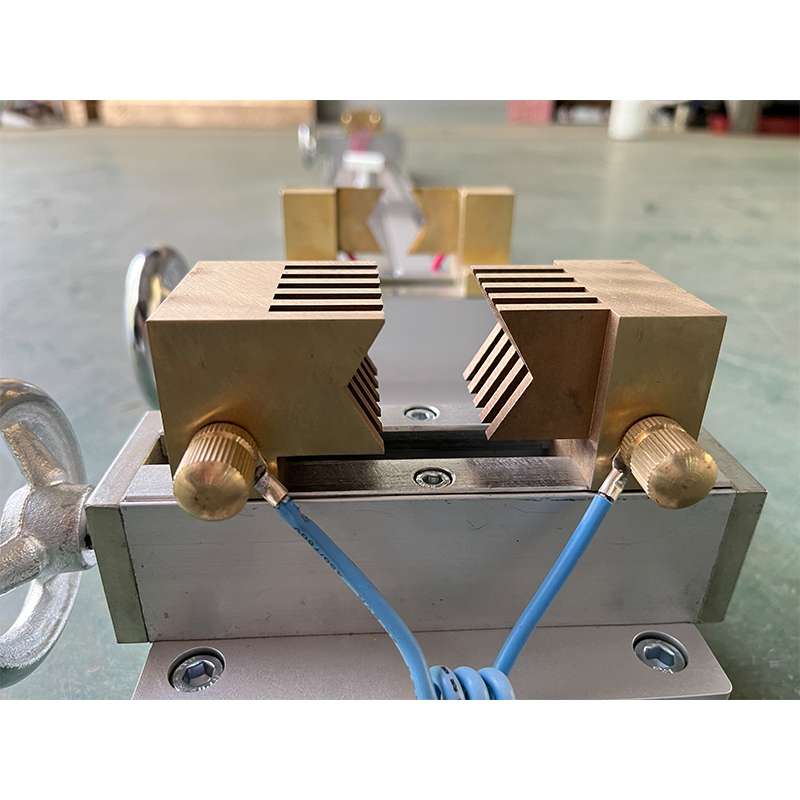

In the ever-evolving world of telecommunications and information technology, coaxial cables play a pivotal role in ensuring efficient data transfer and signal integrity. The production and processing of these cables require precision tools, and one of the most essential among them is the coaxial cable slicer. A coaxial cable slicer factory specializes in the design, manufacture, and distribution of these cutting-edge slicing devices, catering to various industries that rely heavily on coaxial cables.

The coaxial cable slicer is engineered to handle specific requirements, offering the precision and reliability necessary for cutting cables to exact dimensions. In a factory setting, skilled technicians and engineers work together to innovate and improve the functionality of these slicers, ensuring that they meet industry standards. A well-designed coaxial cable slicer can drastically increase productivity by reducing waste and minimizing the time required for manual cutting.

The manufacturing process within a coaxial cable slicer factory begins with the selection of high-quality materials. The durability and strength of the slicers depend largely on the raw materials used. For example, stainless steel components are often employed to ensure longevity and resistance to wear and tear. The factory also invests in advanced technology and machinery to enhance precision during the production process.

Safety is a significant concern in any factory environment. The coaxial cable slicer factory prioritizes creating tools that are not only effective but also safe for operators. Ergonomic designs are built into the slicers, allowing users to work comfortably while minimizing the risk of injury. Safety features, such as automatic shut-off systems and protective casing, are also integrated into the design to keep operators secure during use.

coaxial cable slicer factory

Quality control is another critical aspect of operations in a coaxial cable slicer factory. Each slicer undergoes rigorous testing to ensure it meets the required performance standards before being shipped to clients. This includes testing for cutting accuracy, durability, and user-friendliness. By maintaining high-quality standards, the factory ensures customer satisfaction and builds a robust reputation in the industry.

Furthermore, a coaxial cable slicer factory often engages in continuous improvement practices. Feedback from clients is actively sought to refine existing products and develop new ones that respond to emerging technological trends. For example, as coaxial cable technology evolves, the slicers need to adapt accordingly to handle new cable types and sizes. This commitment to innovation not only solidifies the factory’s market position but also helps in maintaining a competitive edge.

Ultimately, the coaxial cable slicer factory plays a crucial role in supporting the telecommunications industry. By providing high-quality, reliable, and efficient slicing tools, the factory empowers businesses to maintain their operations while ensuring the integrity of their coaxial cable systems. As technology continues to advance and the demand for faster, more reliable data transmission grows, the significance of skilled manufacturers of coaxial cable slicers only increases.

In conclusion, the coaxial cable slicer factory stands as a beacon of precision engineering and quality production. Through its commitment to innovation, rigorous quality control, and emphasis on safety, the factory not only meets the demands of today’s cable manufacturers but also fuels the future of telecommunications. As we move further into an interconnected world, the importance of these specialized tools and the factories that produce them cannot be overstated.

-

Unleashing the Potential of Digital Profile Projectors

NewsMay.22,2025

-

Smoke Density Test Machines for Fire Safety Assessment

NewsMay.22,2025

-

Revolutionizing Testing with Electronic Tensile Tester

NewsMay.22,2025

-

Innovations in Resistance Test Equipment

NewsMay.22,2025

-

Exploring High Performance Cable Cross Linking Equipment

NewsMay.22,2025

-

Advancements in Conductor Resistance Test Equipment

NewsMay.22,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy