Tensile Tester Clamps from Leading Manufacturers for Reliable Testing Solutions

Clamps for Tensile Testers An Overview and Importance in Material Testing

In the realm of materials testing, tensile testing stands out as one of the most essential processes used to determine the mechanical properties of a material. It provides critical data about a material's strength, ductility, and elasticity by measuring its behavior under tension. A vital component in performing these tests accurately is the clamps used to secure the material samples. This article aims to explore the significance of clamps for tensile testers, the various types available, and how manufacturers ensure precision and reliability in crafting these indispensable tools.

The Significance of Clamps in Tensile Testing

Tensile testers, also known as universal testing machines, require a reliable means of securing the test specimen to prevent slippage or damage during the test. The clamps' primary function is to hold the material firmly in place while applying a controlled force until the material breaks or yields. If the clamps do not hold the specimen securely, the test results can be inaccurate, leading to potential failures in practical applications. This makes the quality and design of clamps pivotal in tensile testing.

Types of Clamps

Clamps for tensile testers come in various types, each designed to suit specific material properties and testing requirements. The most common types include

1. Manual Clamps These are operated by hand and typically employ a screw mechanism to grip the specimen tightly. While they offer a degree of flexibility and are cost-effective, they require the user’s skill to ensure uniform application of force.

2. Hydraulic Clamps Utilizing hydraulic pressure, these clamps provide a consistent and strong grip on the specimen, greatly reducing the risk of slippage. They are particularly useful for heavy and larger samples where greater force is needed to secure them.

3. Pneumatic Clamps These are fast and efficient, often used in automated systems. They use compressed air to achieve a strong hold and are ideal for high-throughput testing environments.

clamps for tensile testers manufacturers

4. Wedge Clamps This type of clamp uses a wedging action to secure the specimen. They are particularly advantageous for round samples and can effectively minimize the risk of damage to the material.

5. Grip Pads Manufacturers often provide various grip pad materials that enhance the clamp’s efficacy. For instance, rubber or serrated pads can increase friction and provide superior hold on slick or fragile materials.

Manufacturer Considerations

For manufacturers of tensile testing clamps, precision engineering is paramount. Clamps must be designed and manufactured to exact specifications to ensure they perform effectively across various material types. Some critical considerations include

- Material Selection High-strength alloys and plastics are often chosen for durability and resistance to wear, ensuring that the clamps can withstand repeated use without degrading.

- Surface Finish A smooth finish is essential to prevent damage to the material being tested. Manufacturers implement precise machining and finishing processes to achieve the requisite surface quality.

- Testing Standards Compliance Clamps must adhere to various industry standards (such as ASTM and ISO) to ensure that testing results are reliable and reproducible. Manufacturers often go through rigorous testing and validation processes to confirm compliance.

Conclusion

The importance of clamps for tensile testers cannot be overstated. They play a crucial role in ensuring the accuracy and reliability of tensile testing results, which are foundational for material science and engineering. With advancements in technology, the designs and functionalities of these clamps continue to evolve, paving the way for improved testing procedures. As material testing becomes increasingly critical in various industries, from aerospace to construction, manufacturers of tensile tester clamps must remain at the forefront of innovation, ensuring their products meet the ever-changing demands of modern material testing.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

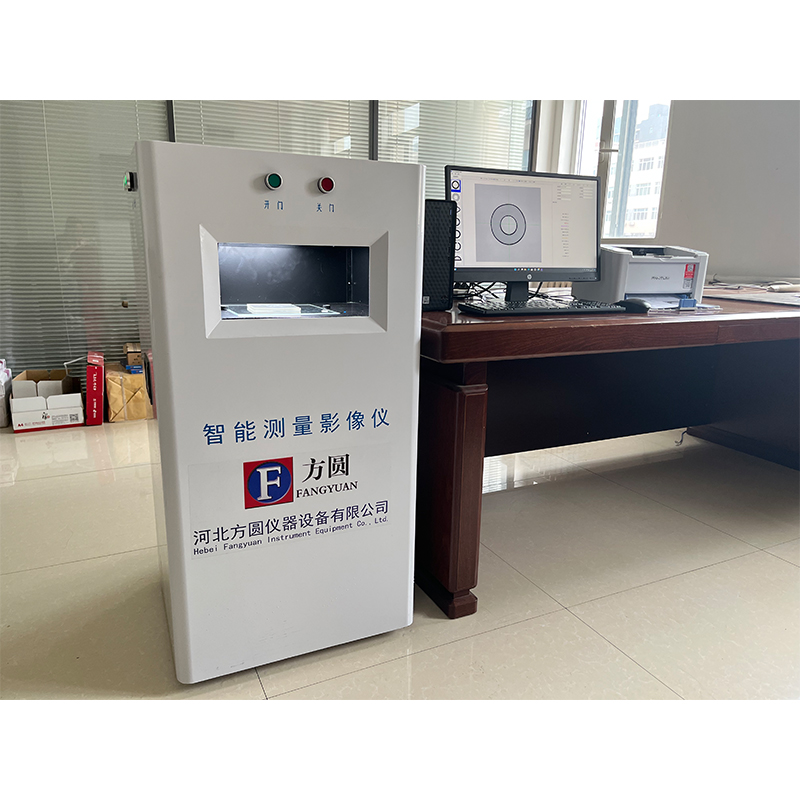

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy