tensile strength tester machine manufacturer

The Role of Tensile Strength Tester Machine Manufacturers in Material Quality Assurance

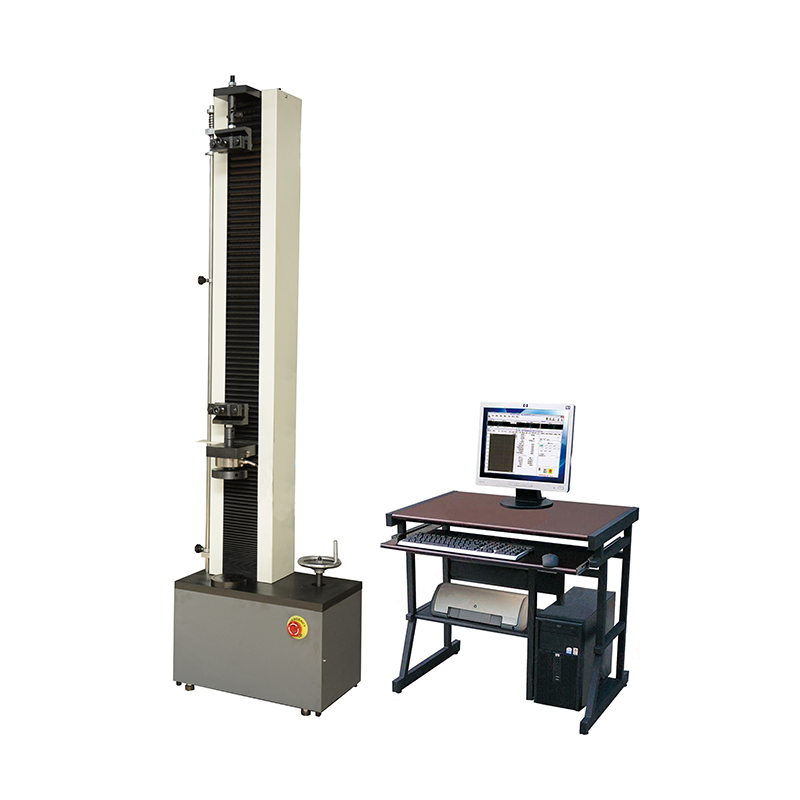

In today’s rapidly advancing industrial landscape, the demand for high-quality materials is more critical than ever. Manufacturers across various sectors, including aerospace, automotive, and construction, rely on robust quality assurance processes to ensure that their products meet safety and performance standards. One of the key components of this quality assurance is the tensile strength tester, a crucial tool used to measure the strength and ductility of materials. This article explores the importance of tensile strength tester machine manufacturers in ensuring the integrity of materials used in various applications.

Understanding Tensile Strength Testing

Tensile strength testing involves pulling a material specimen until it fails to determine its resistance to being pulled apart. The resulting data provides essential insights into several key properties, such as

1. Ultimate Tensile Strength (UTS) The maximum stress a material can withstand while being stretched before breaking. 2. Yield Strength The amount of stress a material can endure before it deforms permanently. 3. Elongation The measure of a material's ability to deform under tensile stress, indicating its ductility.

These properties are vital for engineers and designers, as they help predict how materials will behave under various conditions and loads.

The Role of Manufacturers

Tensile strength tester machine manufacturers play a pivotal role in the quality assurance process. They design and produce testing equipment that meets diverse industry standards, ensuring that materials can be accurately assessed for their applications. Here are some ways in which these manufacturers contribute to material testing

1. Innovative Design Modern tensile strength testing machines are equipped with advanced technology, providing features such as computerized data acquisition, real-time monitoring, and automatic calculations. Manufacturers invest in research and development to enhance the accuracy and user-friendliness of their machines, catering to the needs of various industries.

tensile strength tester machine manufacturer

2. Customization Every industry has unique requirements regarding material testing. Reputable manufacturers offer tailored solutions that address specific testing needs, whether it involves testing metals, polymers, or composites. Customization ensures that businesses can rely on precise and relevant data for their quality assurance processes.

3. Compliance with Standards Tensile strength tester machine manufacturers ensure their products comply with international standards such as ISO, ASTM, and DIN. Compliance not only guarantees the reliability of the testing results but also assures clients that their materials meet the necessary safety and regulatory requirements.

4. Technical Support and Training The relationship between manufacturers and their clients extends beyond the sale of equipment. Many manufacturers provide training and technical support to help customers effectively use the machines and interpret the results. This support is crucial in ensuring that companies can rely on the machines for accurate testing.

The Importance of Quality Assurance

Quality assurance is not merely an operational necessity; it is a critical element that can determine a company's success or failure. In industries where safety is paramount, such as aviation and automotive manufacturing, the failure of a material can lead to catastrophic consequences. By investing in reliable tensile strength testing, companies can mitigate risks associated with material failure, ensure compliance with safety regulations, and maintain their reputation for quality.

Moreover, a well-established quality assurance protocol can lead to significant cost savings. By identifying material weaknesses early through tensile strength testing, companies can avoid costly recall campaigns, improve product reliability, and enhance customer satisfaction.

Conclusion

Tensile strength tester machine manufacturers are integral to the quality assurance landscape. Their commitment to innovation, customization, and compliance with industry standards empowers manufacturers to ensure that their products meet the highest quality benchmarks. As industries continue to evolve and the demand for superior materials grows, the role of tensile strength testing, facilitated by dedicated manufacturers, will undoubtedly become more significant. For businesses aiming to thrive in competitive markets, partnering with reputable tensile strength tester machine manufacturers is not just an option, but a necessity.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy