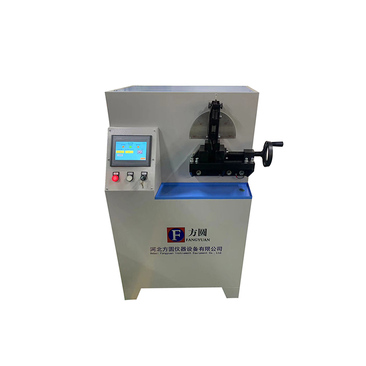

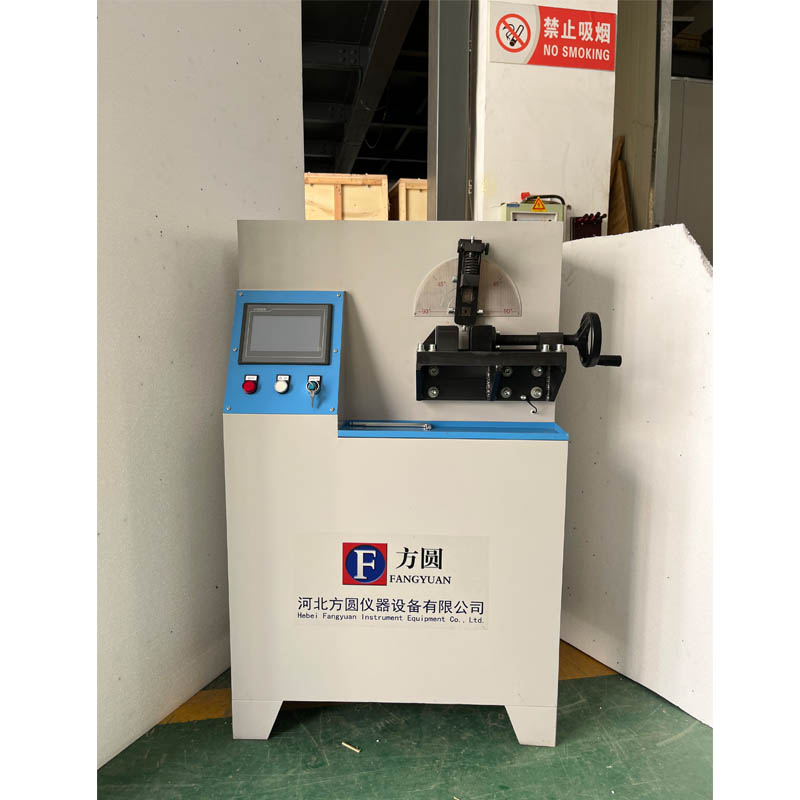

JWJ-10 Metal Wire Repeated Bending Test Machine

توضیحات محصول

This testing machine is mainly used for the reverse bending test of metal wire, thin plate and thin strip, in order to check the performance of metal materials to withstand plastic deformation and obvious defects in reverse bending.

Testing principle: the sample of certain specification is clamped in two jaw of specified size through the guide sleeve, and the machine is started. The sample is bent at 90° left and right. After the sample breaks, the machine stops automatically and the bending times are recorded.

Applicable standards

GB/T 238-2013 “Metallic materials wire rod bending test method”

GB/T4909.5-2009 “Test methods for bare wires Part 5: Bending test - Reverse bending”

TB/T2809-2005 “Copper and copper alloy contact wire for electrified railway”

GB/T235-2013 “Test method for reverse bending of sheet and strip of metallic materials with thickness equal to or less than 3 mm”

امکانات

1. Replacing clamping jaws with different specifications allows for bending tests of various specifications of materials;

2. PLC programming, frequency converter control motor, touch screen operation, and adjustable bending speed.

3. Stable performance, compact structure, reliable quality, suitable for long-term work;

4. Quick tensioning device, easy to operate

پارامتر فنی

|

Applicable materials |

Metal wire |

|

Max. bending diameter |

1 ~ 10mm |

|

طول نمونه |

300 ~ 400mm |

|

Bending angle |

90 ° left and right each |

|

Circular cross section wire rod |

≤Φ6mm |

|

Numbers of bending jaws for circular cross section wire rod |

One pair of r1.25, 1.75, 2.5, 3.75, 5.0, 7.5, 10 and 15, R20 and R25 are optional |

|

Irregular section wire rod |

≤Φ8mm |

|

Numbers of bending jaws for irregular section wire rod |

One pair of r1.25, 1.75, 2.5, 3.75, 5.0, 7.5, 10,15,20 and R25 is optional |

|

Bending speed |

10 ~ 75 times / min adjustable |

|

Motor Power |

Vertical three-phase 1.5kw |

|

Overall dimensions(mm) |

760(L) x 550(W) x 1210(H) |

|

منبع تغذیه |

Three-phase four-wire system 220 / 380V / 50Hz |

Specification For Application Of Wire

|

Nominal diameter of wire rod |

Jaw support radius(r) |

Range(h) |

Guide sleeve hole diameter(d)(g) |

|

0.3≤d<0.5 |

1.25±0.05 |

15 |

2.0 |

|

0.5≤d<0.7 |

1.75±0.05 |

15 |

2.0 |

|

0.7≤d<1.0 |

2.5±0.1 |

15 |

2.0 |

|

1.0≤d<1.5 |

3.75±0.1 |

20 |

2.0 |

|

1.5≤d<2.0 |

5.0±0.1 |

20 |

2.0 and 2.5 |

|

2.0≤d<3.0 |

7.5±0.1 |

25 |

2.5 and 3.5 |

|

3.0≤d<4.0 |

10±0.1 |

35 |

3.5 and 4.5 |

|

4.0≤d<6.0 |

15±0.1 |

50 |

4.5 and 7.0 |

|

6.0≤d<8.0 |

20±0.1 |

75 |

7.0 and 9.0 |

|

8.0≤d<10.0 |

25±0.1 |

100 |

9.0 and 11.0 |