Customized Electromechanical Universal Tensile Testing Machine for Material Strength Assessment

Custom Electromechanical Universal Tensile Tester An Essential Tool for Material Testing

In the realm of materials science and engineering, the demand for precision and reliability in testing methods is paramount. One essential tool that meets these requirements is the custom electromechanical universal tensile tester. This versatile equipment is crucial for conducting a wide range of mechanical tests on materials, providing valuable insights into their strength, ductility, and overall performance.

Understanding the Electromechanical Universal Tensile Tester

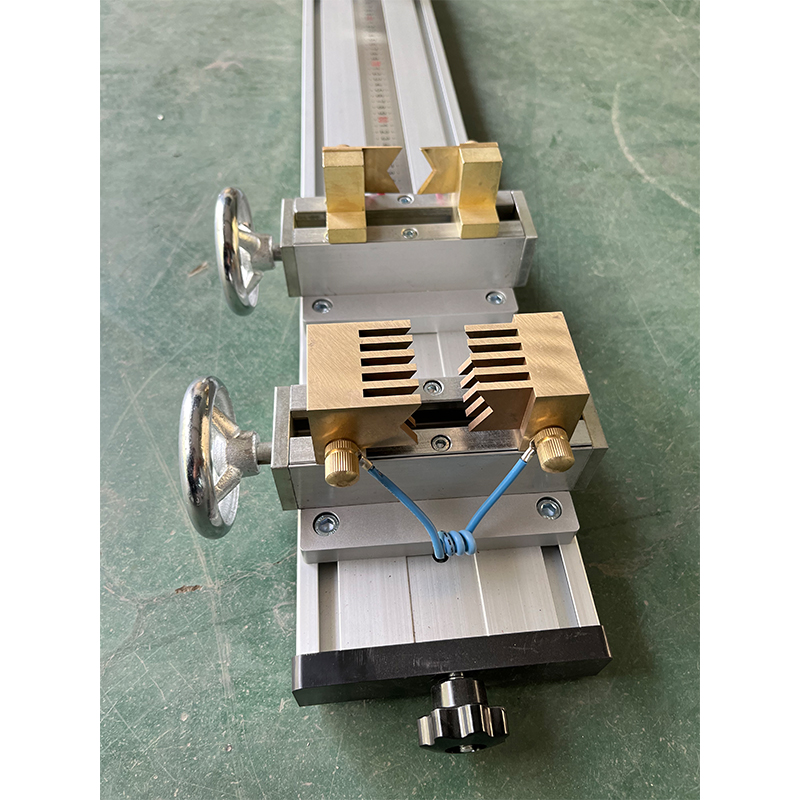

At its core, an electromechanical universal tensile tester is designed to apply tension to materials to determine their mechanical properties. It utilizes advanced electromechanical systems to control the testing process, ensuring accurate and repeatable results. The key components of a typical tensile tester include a load cell, gripping fixtures, a crosshead for applying force, and a data acquisition system to capture and analyze the results.

The versatility of these testers allows them to accommodate various testing standards, including ASTM, ISO, and other industry-specific guidelines, making them suitable for various applications across different sectors, including automotive, aerospace, plastics, textiles, and metals.

Customization for Specific Needs

One of the significant advantages of using a custom electromechanical universal tensile tester is the ability to tailor the machine to meet specific testing needs. Manufacturers can design these testers to suit unique material properties and testing requirements. This customization may involve adjusting the load capacity, altering the testing speed, or equipping the tester with specialized grips and fixtures that cater to particular materials or test geometries.

For instance, companies focusing on the petroleum or chemical industries might require testers that can assess the tensile strength of polymer blends under various environmental conditions

. Customizing the electromechanical tensile tester ensures that it can effectively simulate real-world conditions, providing more accurate results that are crucial for material selection and quality assurance.Enhanced Features for Improved Testing

Modern electromechanical universal tensile testers come equipped with advanced features that significantly enhance testing capabilities. These may include

custom electromechanical universal tensile tester

1. Computer-Controlled Systems Many testers employ sophisticated software that allows for precise control over testing parameters, enabling users to program specific testing protocols and automatically calculate various material properties, such as tensile strength, elongation, and modulus of elasticity.

2. Real-Time Data Monitoring The integration of real-time data monitoring systems allows operators to observe the testing process as it happens. Users can visualize stress-strain curves on the fly, facilitating immediate analysis and decision-making.

3. Multiple Testing Modes Custom tensile testers can be configured to perform various types of mechanical tests, including tensile, compression, bend, and shear tests, making them multifunctional and efficient.

4. User-Friendly Interfaces Advanced graphical user interfaces (GUIs) simplify operation, allowing even novice users to navigate through the testing process efficiently.

Applications Across Industries

Custom electromechanical universal tensile testers find applications in a multitude of industries. In the automotive sector, they are crucial for evaluating the performance of components subjected to various stresses. In the textile industry, they help assess the durability and strength of fabrics. Even in the electronics realm, tensile testers are employed to ensure the reliability of connectors and cables.

Moreover, research institutions utilize these testers to perform extensive studies on new materials, pushing the boundaries of innovation. As new materials, such as composites or advanced alloys, emerge, the demand for accurate and if possible, customized testing solutions will only grow.

Conclusion

The custom electromechanical universal tensile tester stands as a pillar in the field of material testing. Its ability to be tailored to specific needs combined with its advanced features ensures that professionals across various industries can conduct reliable and precise mechanical tests. As technology advances and material properties continue to evolve, the importance of having a customizable, versatile tensile tester becomes increasingly vital in ensuring product integrity and enhancing material performance. By investing in such essential testing equipment, companies and researchers can make informed decisions that lead to superior materials and ultimately, better products.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy