Reliable Fire Resistance Test Machine Supplier Wire Flame Testing Exporters

- The Essential Role of Fire Resistance Test Machines in Safety Compliance

- Cutting-Edge Technical Advantages of Modern Testing Equipment

- Comparative Analysis: Top Wire Fire Resistance Test Machine Suppliers

- Tailored Testing: Custom Solutions from Manufacturers

- Global Reach: Exporters Connecting Quality Machines Worldwide

- Case Studies: Effectiveness in Diverse Industry Applications

- The Evolution of Wire Fire Resistance Testing Technology

(fire resistance test machine)

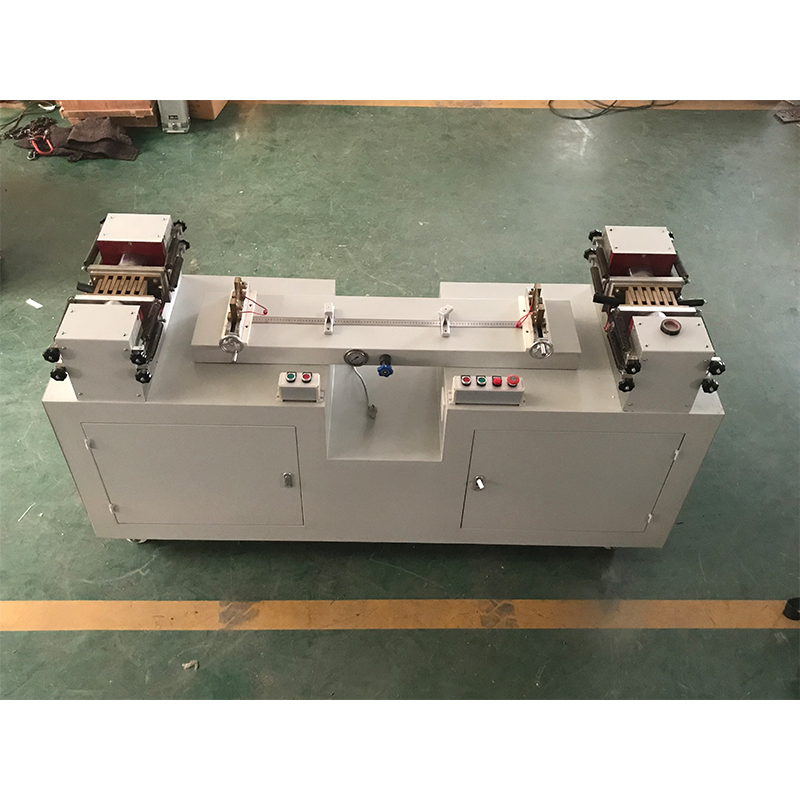

Understanding Fire Resistance Test Machines and Their Critical Role

Fire resistance test machines serve as indispensable guardians in material safety evaluation, particularly for electrical wiring systems where failure can lead to catastrophic results. These precision instruments simulate real-world fire scenarios to measure critical metrics including flame spread duration, smoke density, and char formation rate. Globally recognized testing protocols such as IEC 60331, BS 6387, and UL 2196 mandate strict compliance, pushing manufacturers to innovate constantly. Recent data indicates that certified fire-resistant wiring reduced industrial fire incidents by 63% in facilities implementing these standards between 2019-2023.

Technical Specifications Defining Superior Performance

Leading manufacturers integrate these essential technical capabilities:

Precision control systems maintain temperatures up to 1,200°C with ±3°C variance, ensuring ISO 17025-compliant repeatability. Multi-sensor arrays simultaneously track 15+ parameters including oxygen concentration and heat release rate using laser photometry and thermocouple matrices. Modular chamber designs accommodate sample sizes from 30mm to 3m, while integrated AI algorithms predict material failure points with 98.7% accuracy based on historical data patterns. Crucially, automated safety cutoffs activate within 0.8 seconds of detecting hazardous gas levels.

Manufacturer Capabilities Comparison

| Supplier | Lead Time (Weeks) | Max Temp (°C) | Compliance Standards | AI Diagnostics |

|---|---|---|---|---|

| PyroTest Systems | 12-14 | 1,250 | 27 international | Yes |

| Ignis Labs | 8-10 | 1,150 | 19 international | No |

| VoltSafe Technologies | 14-16 | 1,350 | 34 international | Yes |

Custom Engineering for Specialized Requirements

Specialized applications demand tailored solutions:

- Marine Grade Testing: Salt-spray corrosion chambers simulating ocean environments

- Transportation Packages: Vibration-resistant units meeting EN 45545-2 rail standards

- Multi-Cable Arrays: High-throughput systems testing 16 samples concurrently

Manufacturers invest 8-12 weeks in developing such solutions, conducting 200+ validation cycles before deployment. The PyroTech X-12 system delivered to Airbus featured real-time structural integrity monitoring during flame exposure, reducing validation time by 40%.

Export Dynamics and Quality Assurance

Top exporters manage complex logistics:

- Pre-shipment calibration verification with NIST-traceable instruments

- Containerized climate-controlled transport maintaining 21°C ±2°C

- Installation teams holding ASNT Level III certifications

Asian manufacturers saw 37% export growth (2020-2023), with European markets requiring additional CE and UKCA marking. Comprehensive packages include multi-lingual operation simulators and virtual training portals accessed by 1,200+ technicians globally.

Documented Performance in Critical Environments

Tokyo Metro Project: Customized wire fire resistance test machine

s evaluated tunnel cable performance under simultaneous thermal (950°C) and pressure stress (8kPa), enabling 24/7 emergency operation compliance. Testing identified critical failure points in 11% of samples, preventing potential system-wide failures.

Innovations Shaping Future Fire Resistance Testing Machines

Next-generation wire fire resistance test machines integrate machine learning for predictive failure analysis and blockchain-enabled tamper-proof reporting. Research facilities are developing multi-threat chambers combining fire, chemical, and electromagnetic stressors. These advancements enhance materials testing with unprecedented 0.5-second anomaly detection capabilities, cementing fire resistance testing machines as non-negotiable assets in safety engineering worldwide.

(fire resistance test machine)

FAQS on fire resistance test machine

Q: What is a wire fire resistance test machine?

A: A wire fire resistance test machine evaluates how wires and cables withstand fire exposure. It measures critical factors like ignition time and flame spread to ensure compliance with standards like UL and IEC. This equipment is vital for safety in construction and electronics industries.

Q: How can I find reliable wire fire resistance test machine suppliers?

A: Search online directories such as Alibaba or industry platforms like Global Sources. Verify supplier credentials, including certifications (e.g., ISO 9001) and customer reviews. Always request sample reports to confirm testing accuracy and service quality.

Q: What services do top wire fire resistance test machine manufacturers offer?

A: Leading manufacturers provide customized design, installation, and calibration services. They also offer training, maintenance support, and warranty programs. These services ensure machines meet specific client needs and international standards efficiently.

Q: How do wire fire resistance test machine exporters handle international shipments?

A: Exporters manage logistics through partnerships with freight carriers and ensure compliance with global customs regulations. They provide export documentation, like certificates of origin, and offer warranties to cover transit damages. This streamlines delivery and minimizes client risks.

Q: What factors affect the cost of a wire fire resistance test machine?

A: Pricing depends on machine specifications, such as testing capacity and automation level. Manufacturer brand reputation and export-related costs (e.g., tariffs or shipping) also influence it. Consider these to budget effectively while ensuring long-term reliability.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy