ژانویه . 09, 2025 13:45

Back to list

FY-NHZ Cable Fire Resistance Characteristics Test Equipment(Mass Flow Controller)

The wire and cable testing machine is a crucial component for ensuring the reliability and safety of electrical systems. As industries strive towards achieving higher standards, the demand for precise testing methodologies has surged. This article explores the critical role that wire and cable testing machines play, drawing from real-world experiences and expert perspectives to offer an authoritative insight into their functionality and impact.

Renowned certification bodies reinforce the trust placed in wire and cable testing machines by incorporating strict validation protocols before approving these devices for industrial use. This layer of verification adds an additional layer of trustworthiness, assuring end-users that the machines are fit for purpose. Manufacturers who prioritize these testing processes report increased customer satisfaction and fewer product recalls, translating to measurable business success. Investing in a robust testing regime is not merely a cost but a strategic initiative that fortifies brand reputation and positions companies as leaders in quality assurance. A common misperception is that wire and cable testing is a one-time process. However, continuous verification and recalibration of testing machines ensure ongoing accuracy and reliability. Industry experts advocate for routine maintenance schedules and periodic training sessions to keep testing equipment and personnel up to date with the latest practices. As we navigate an era of heightened accountability and technological advancements, the role of wire and cable testing machines remains indispensable. Their contribution to ensuring product reliability cannot be overstated, underpinning the ecosystems that drive modern innovation and infrastructure. In conclusion, wire and cable testing machines stand as paragons of experience, expertise, and trust within the industrial landscape. Their presence not only bolsters product safety but also enhances the credibility and reputation of manufacturers committed to delivering excellence. As technology evolves, so too will the capabilities of these machines, continuously paving the way toward safer and more reliable electrical systems worldwide.

Renowned certification bodies reinforce the trust placed in wire and cable testing machines by incorporating strict validation protocols before approving these devices for industrial use. This layer of verification adds an additional layer of trustworthiness, assuring end-users that the machines are fit for purpose. Manufacturers who prioritize these testing processes report increased customer satisfaction and fewer product recalls, translating to measurable business success. Investing in a robust testing regime is not merely a cost but a strategic initiative that fortifies brand reputation and positions companies as leaders in quality assurance. A common misperception is that wire and cable testing is a one-time process. However, continuous verification and recalibration of testing machines ensure ongoing accuracy and reliability. Industry experts advocate for routine maintenance schedules and periodic training sessions to keep testing equipment and personnel up to date with the latest practices. As we navigate an era of heightened accountability and technological advancements, the role of wire and cable testing machines remains indispensable. Their contribution to ensuring product reliability cannot be overstated, underpinning the ecosystems that drive modern innovation and infrastructure. In conclusion, wire and cable testing machines stand as paragons of experience, expertise, and trust within the industrial landscape. Their presence not only bolsters product safety but also enhances the credibility and reputation of manufacturers committed to delivering excellence. As technology evolves, so too will the capabilities of these machines, continuously paving the way toward safer and more reliable electrical systems worldwide.

Latest news

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

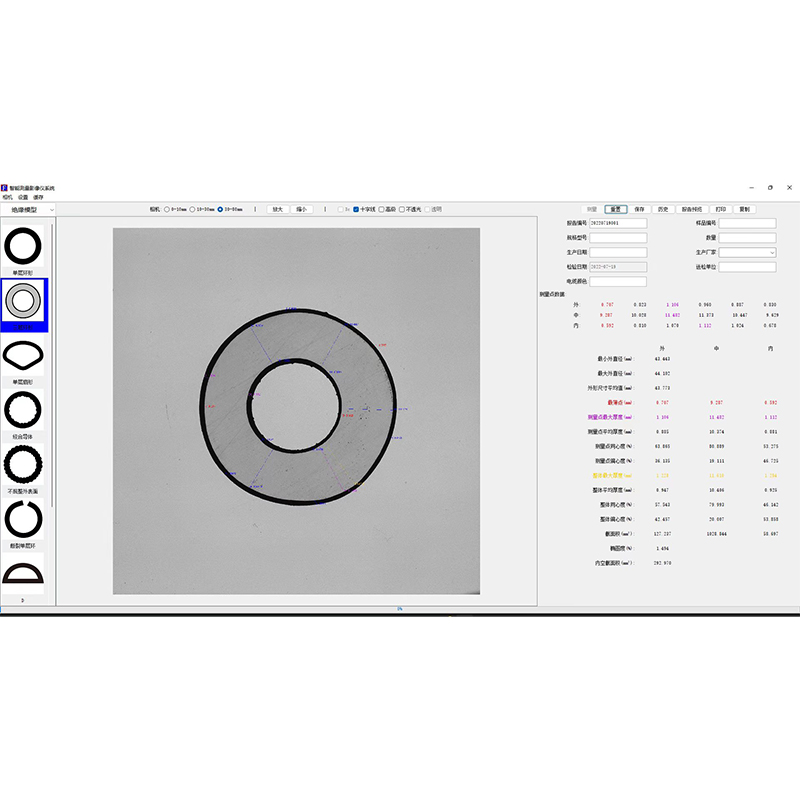

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy