Tailored Electronic Tensile Testing Equipment for Precise Material Strength Evaluation

Custom Electronic Tensile Testing Machines An Essential Tool for Material Testing

In the realm of materials science and engineering, understanding the mechanical properties of materials is fundamental. Tensile testing, in particular, serves as a crucial method for evaluating strength, ductility, and elasticity of materials. A custom electronic tensile testing machine provides researchers, engineers, and manufacturers with the precision and versatility needed to obtain accurate material properties tailored to specific requirements.

What is a Tensile Testing Machine?

A tensile testing machine, often known as a universal testing machine (UTM), is designed to test the tensile strength of materials by applying a uniaxial force until failure occurs. The machine gradually pulls the sample until it breaks, measuring the force applied and the elongation of the material. This data is critical as it helps determine key properties such as yield strength, ultimate tensile strength, and elongation at break.

Advantages of Customization

One of the significant advantages of custom electronic tensile testing machines lies in their ability to be tailored to meet specific testing applications. Standard machines might not always address unique material characteristics or testing standards required for specialized industries. Customization can include variations in load cell capacity, frame size, grips, and clamps designed to accommodate different geometries and material types.

For example, in research settings, scientists may need to test advanced materials like composites, lightweight alloys, or polymers that require specific loading techniques and conditions. A custom machine can be engineered to meet those unique requirements, ensuring that the data collected is both accurate and relevant.

Integration of Electronic Components

Modern tensile testing machines integrate highly advanced electronic components to enhance their performance. The incorporation of digital displays, software for monitoring data in real-time, and automated control systems allows for precise adjustments and documentation. Users can easily set parameters such as load rate, extension limits, and other testing conditions through user-friendly interfaces.

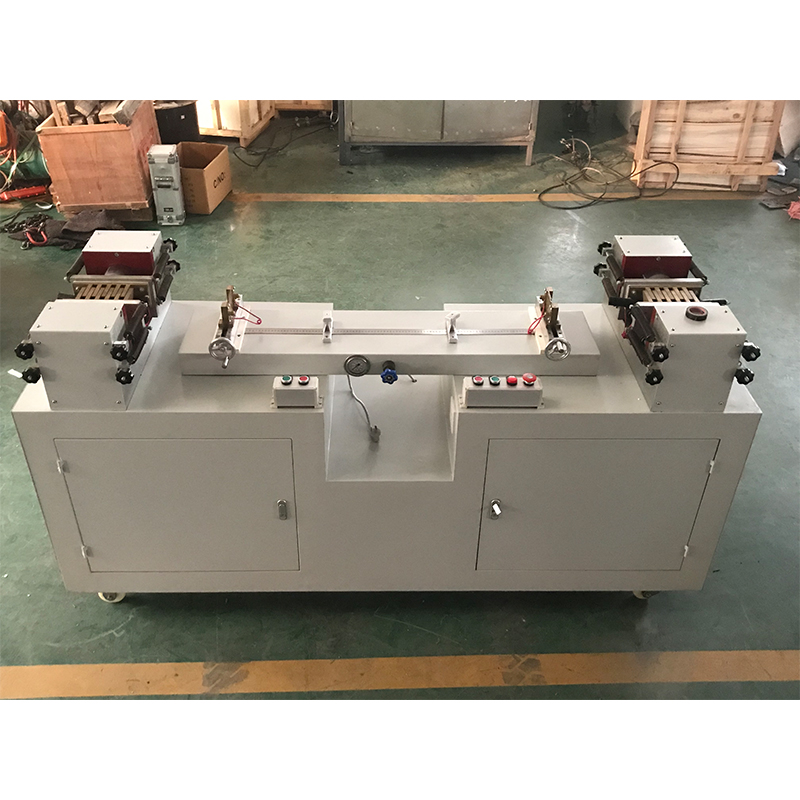

custom electronic tensile testing machine

Moreover, data acquisition systems collect vast amounts of data during testing, allowing for real-time analysis. This has opened the door for sophisticated analysis techniques, including stress-strain curves and other graphical data representation, providing deeper insights into material behavior under stress.

Applications in Various Industries

Custom electronic tensile testing machines find applications across numerous industries.

1. Aerospace and Automotive Stringent weight and safety standards necessitate materials that can withstand extreme stress. Tensile testing machines are employed to ensure that components meet these standards, guaranteeing both performance and safety.

2. Construction In the construction sector, materials such as steel, concrete, and various composites are tested to confirm their structural integrity and performance under different loads.

3. Biomaterials In the field of biomedical engineering, tensile testing is crucial for assessing the properties of biomaterials used in implants and prosthetics, ensuring that they mimic the properties of natural tissues.

4. Textiles The textile industry relies heavily on tensile testing to evaluate the strength and elasticity of fabrics, ensuring durability in products ranging from clothing to industrial textiles.

Conclusion

In conclusion, custom electronic tensile testing machines are invaluable assets in various fields of research and industry. Their ability to be tailored for specific applications ensures that they meet the rigorous demands of material characterization. As technology advances, these machines will continue to evolve, incorporating innovative features that enhance accuracy, usability, and data analysis capabilities. For businesses and researchers alike, investing in a tailored tensile testing solution can significantly impact the quality and performance of materials, translating into safer, more reliable products for end-users. As industries continue to innovate and develop new materials, the role of custom electronic tensile testing machines will become even more critical in ensuring their integrity and performance.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy