DC Insulation Resistance Tester Manufacturer for Reliable Electrical Testing Solutions

Understanding DC Insulation Resistance Testers A Comprehensive Overview of Manufacturing and Application

In the world of electrical engineering and maintenance, safety is of utmost importance. One of the critical aspects of ensuring safety in electrical systems is the insulation resistance testing. This is where DC insulation resistance testers come into play. These devices are essential tools used for measuring the resistance of insulation in various electrical systems, ensuring that they are safe and functioning efficiently. This article delves into the functionalities, significance, and manufacturing of DC insulation resistance testers.

What is a DC Insulation Resistance Tester?

DC insulation resistance testers are specialized instruments designed to apply a high DC voltage to electrical insulation to gauge its resistance. This resistance is crucial for determining the integrity of the insulation as it protects electrical components from current leakage and potential failure. Typically, the testers work by applying a voltage ranging from 50V to 2500V, depending on the specific requirements of the test and the insulation material being evaluated.

Why is Insulation Resistance Testing Important?

Insulation resistance testing serves multiple purposes

1. Preventing Electrical Failures Over time, insulation can degrade due to environmental factors, mechanical wear, or chemical exposure. Regular testing helps identify potential weaknesses before they lead to electrical failures.

2. Ensuring Safety Poor insulation can lead to leakage currents, posing serious risks, including electric shocks, fires, and damage to sensitive equipment. Testing insulation ensures that all electrical systems are operating within safe parameters.

3. Compliance with Standards Many industries are governed by strict regulations regarding electrical safety. Conducting insulation resistance tests ensures compliance with these regulations, which can vary from one jurisdiction to another.

4. Maintenance Scheduling Regular testing allows organizations to implement predictive maintenance strategies. By identifying insulation failures early, businesses can avoid costly downtimes and service interruptions.

Manufacturing of DC Insulation Resistance Testers

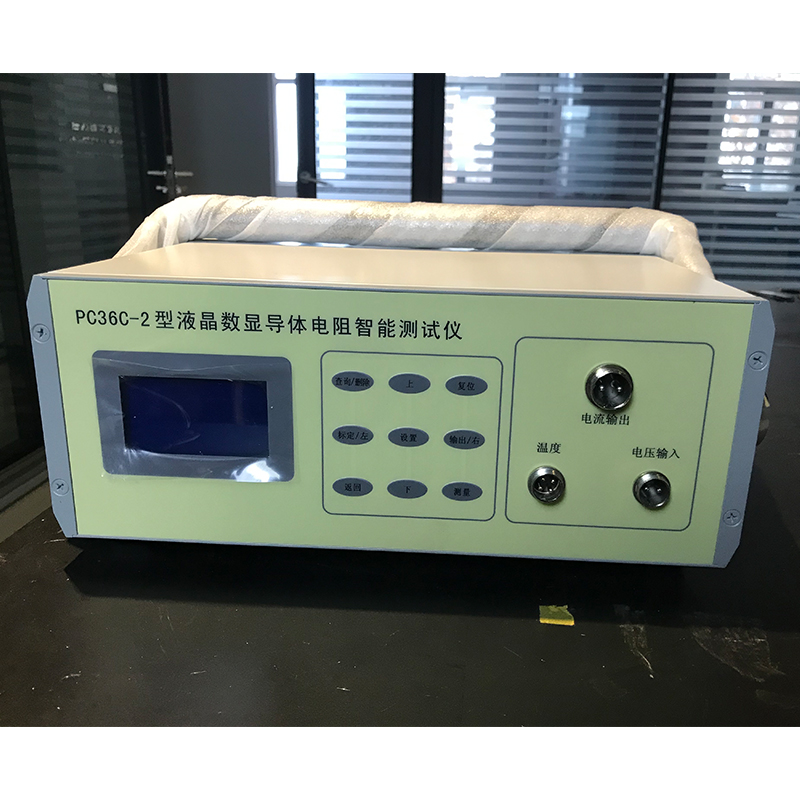

dc insulation resistance tester factory

The manufacturing process of DC insulation resistance testers is intricate and requires precision engineering

. Manufacturers typically follow these critical steps1. Design and Engineering Initially, the design of the tester must be developed, adhering to industry standards and regulations. Engineers select components based on durability, accuracy, and user-friendliness.

2. Component Sourcing Quality components, including high-voltage capacitors, resistors, and microcontrollers, are sourced. The reliability of these components is crucial, as they directly impact the tester's performance.

3. Assembly Once components are received, they are assembled by skilled technicians. This process often involves soldering and the integration of circuit boards into enclosures designed to withstand electrical stresses and environmental conditions.

4. Testing and Calibration Each unit undergoes rigorous quality control procedures, including testing under simulated conditions. Calibration ensures that the meters provide accurate readings across the entire range of measurement.

5. Packaging and Distribution After passing quality control, the testers are carefully packaged for distribution. Manufacturers often include detailed user manuals and certification documents, ensuring that users can operate the equipment safely and effectively.

The Future of DC Insulation Resistance Testing

As technology advances, the future of DC insulation resistance testers looks promising. Innovations such as digital displays, data logging capabilities, and smartphone integration are becoming more common. These features enhance usability and allow for easier data analysis, which can aid in decision-making processes.

Moreover, with the rise of renewable energy systems and electric vehicles, the demand for reliable insulation testing is expected to increase. Manufacturers will need to adapt their products to cater to these new sectors, ensuring that they meet the unique challenges posed by modern electrical systems.

Conclusion

DC insulation resistance testers play a pivotal role in maintaining electrical safety and equipment integrity. Understanding their importance, manufacturing processes, and future developments is essential for anyone involved in electrical engineering or maintenance. As industries continue to evolve, so too will these invaluable tools, ensuring that we remain safe in our increasingly electrified world.

-

Unleashing the Potential of Digital Profile Projectors

NewsMay.22,2025

-

Smoke Density Test Machines for Fire Safety Assessment

NewsMay.22,2025

-

Revolutionizing Testing with Electronic Tensile Tester

NewsMay.22,2025

-

Innovations in Resistance Test Equipment

NewsMay.22,2025

-

Exploring High Performance Cable Cross Linking Equipment

NewsMay.22,2025

-

Advancements in Conductor Resistance Test Equipment

NewsMay.22,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy