Supplier of Winding and Torsion Testing Equipment for Quality Assurance and Testing Solutions

Understanding Winding and Torsion Testing Machines Key Suppliers and Their Importance

In the realms of manufacturing and materials testing, the functionality and reliability of products are paramount. This is where winding and torsion testing machines come into play. These specialized machines are essential for evaluating the strength and durability of materials and components subjected to torsional loads and winding stress during their operational life. As industries seek precise and efficient testing solutions, the demand for high-quality machines and reliable suppliers rises.

What Are Winding and Torsion Testing Machines?

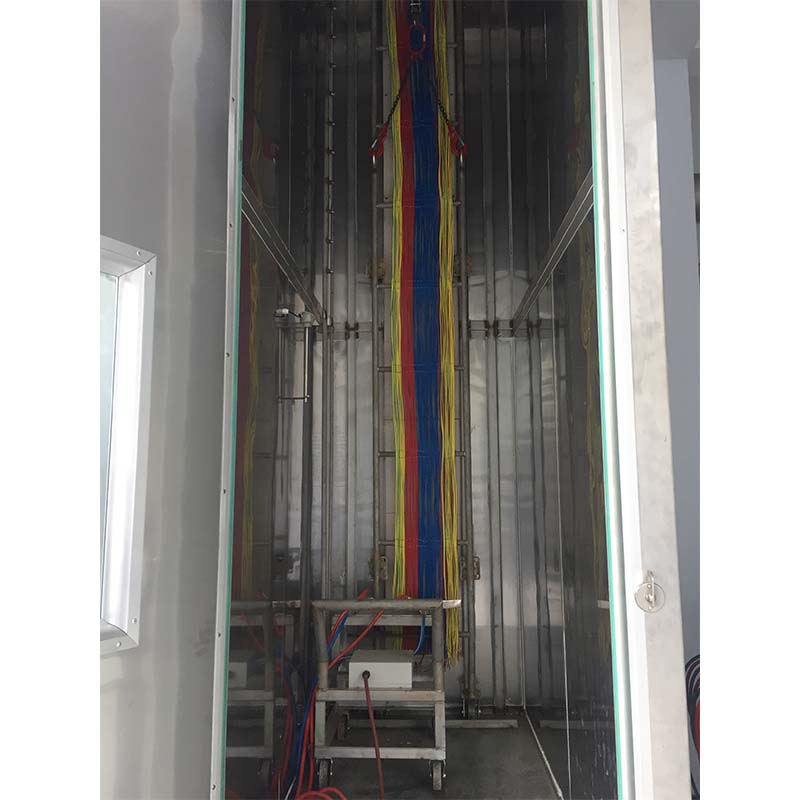

Winding testing machines are designed to test the performance of materials under various winding conditions. This includes assessing how materials behave when they are subjected to winding processes typically found in textile, wire, and cable industries. Torsion testing machines, on the other hand, evaluate the behavior of materials when twisted. These tests are crucial for materials intended for applications where torque or twisting forces are expected, such as in automotive and aerospace components.

The results from these tests help engineers and manufacturers identify potential weaknesses in materials and designs, ensuring that only reliable and robust products reach the market. Consequently, investing in advanced testing equipment is essential for maintaining product quality and adherence to industry standards.

Importance of Choosing the Right Supplier

Choosing a reputable supplier for winding and torsion testing machines is critical. The supplier's experience, the quality of machinery they provide, and their after-sales support can significantly affect the testing process and outcomes. Here are several key factors to consider when selecting a supplier

1. Quality of Machines The durability and precision of testing machines can vary significantly between manufacturers. It is crucial to select a supplier that offers high-quality machines, ensuring consistent and accurate test results.

2. Customization Options Different industries have unique testing requirements. A good supplier should provide customization options to tailor machines to specific testing needs, enhancing flexibility and usability.

winding and torsion testing machine supplier

3. Technical Support and Training Adequate support and training are essential for operating complex machinery. Suppliers that offer comprehensive training programs and responsive technical support instill confidence in their customers.

4. Reputation and Experience Suppliers with a solid reputation and years of experience in the industry often deliver products that have been tested and validated by other customers. Looking into customer testimonials and case studies can offer insight into a supplier’s reliability.

5. Compliance with Standards It is vital that the machines comply with relevant industry standards and regulations to ensure that all testing is credible and accepted globally. A supplier that prioritizes these compliance measures can be more advantageous in the long run.

Leading Suppliers in the Market

Several suppliers stand out in the market for winding and torsion testing machines. Companies like Instron, ZwickRoell, and MTS Systems are recognized for their cutting-edge technology and reliable machines. These suppliers not only provide high-quality testing machines but also offer ongoing support and resources to help clients maximize their investments.

Additionally, emerging companies with innovative solutions are making their mark by supplying cost-effective and versatile testing equipment. These suppliers are often more agile and can provide customized solutions faster than larger corporations.

Conclusion

The application of winding and torsion testing machines is critical across various industries, from manufacturing to research and development. These machines provide essential data that helps in enhancing product reliability and performance. Selecting a reputable supplier is equally important to ensure that businesses are equipped with the best technology for their testing needs. By focusing on quality, customization, support, and compliance with industry standards, organizations can make informed decisions that will ultimately lead to successful outcomes. In this ever-evolving landscape, investing in the right testing machines from reliable suppliers is not just a choice but a necessity for staying competitive and ensuring product integrity.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy