Innovative Cable Cutting Solutions from a Leading Manufacturing Facility for Efficient Production Processes

The Evolution and Impact of Cable Slicer Factories

In today's rapidly advancing technological landscape, the demand for efficient and reliable cable management systems is more pressing than ever. One of the unsung heroes in this industry is the cable slicer, a device that plays a crucial role in the manufacturing and installation of cables. Cable slicer factories are essential to meet the increasing needs of various sectors, including telecommunications, construction, and automobile industries.

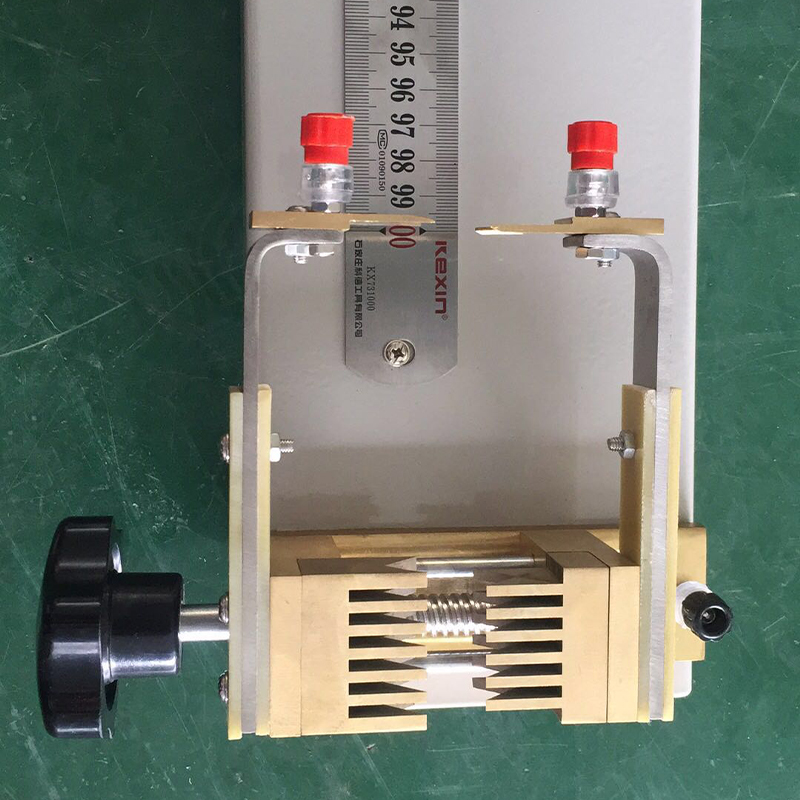

A cable slicer is a machine designed to cut cables to precise lengths while ensuring clean and accurate edges. The functionality of these machines extends beyond mere cutting; they can also strip insulation, blade cable wrappers, and even twist multiple wires together. This versatility makes cable slicers indispensable in the production process. In cable slicer factories, these machines are often the backbone of operations, facilitating a seamless workflow that enhances productivity.

The Evolution and Impact of Cable Slicer Factories

Moreover, the growth of the renewable energy sector has sparked a surge in demand for cables used in solar and wind energy systems. As these industries expand, cable slicer factories are adjusting their output to cater to these specific needs. For instance, specialty cables that require unique cutting techniques are becoming more prevalent, prompting manufacturers to invest in research and development to create advanced slicing solutions tailored for these applications.

cable slicer factory

Cable slicer factories are also committed to sustainability. With growing awareness of environmental issues, many manufacturers are seeking ways to minimize waste and energy consumption during production. Innovations such as blade slicing technology and efficient waste management systems are being implemented to reduce the environmental footprint of cable slicing. Factories are now adopting eco-friendly materials for their packaging and investing in energy-efficient machines that not only lower operational costs but also contribute to a greener planet.

In addition to operational efficiency, safety standards in cable slicer factories are paramount. With the use of high-speed machinery, the potential for workplace accidents is significant. Manufacturers are therefore prioritizing the safety of their employees by incorporating safety measures, such as protective guards and emergency stop functions, into their machines. Training workers on best safety practices is also a crucial aspect of factory operations.

Furthermore, the competitive landscape of cable production is pushing factories to innovate continuously. To remain relevant, cable slicer factories must not only enhance their product quality but also improve their customer service. This includes offering customized slicing solutions that meet client specifications and quick turnaround times that cater to urgent orders. Establishing strong relationships with clients leads to repeat business and a solid reputation in the marketplace.

In conclusion, cable slicer factories are vital contributors to the modern manufacturing ecosystem. Their role in streamlining cable production, adapting to new market demands, prioritizing sustainability, and ensuring workplace safety cannot be overstated. As technology continues to evolve, these factories will undoubtedly play an integral part in shaping the future of cable management solutions, paving the way for more efficient and innovative practices in the industry. The ongoing evolution of cable slicers and their manufacturing processes promises to uphold the quality and efficiency that modern industries require.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy