resistance test equipment manufacturer

The Importance of Resistance Test Equipment Manufacturers in Electrical Safety

In today's world, electrical safety is a paramount concern across various industries, from manufacturing to utilities and even construction. Ensuring that electrical installations are safe and compliant with regulatory standards is crucial. One of the significant players in guaranteeing electrical safety is resistance test equipment manufacturers. Their contributions to the field cannot be overstated.

Understanding Resistance Testing

Resistance testing is a vital process used to evaluate the integrity and functionality of electrical systems. It helps in identifying issues such as insulation failures, grounding problems, and the overall performance of electrical circuits. The core principle behind resistance testing is Ohm’s law, which states that the resistance (R) is equal to the voltage (V) divided by the current (I). This fundamental principle enables technicians to assess how well an electrical system is functioning.

One of the most common types of resistance testing is insulation resistance testing. This test measures the resistance between the conductors and the earth to ensure that the electrical insulation is intact. Low insulation resistance can lead to short circuits or electrical leakage, which can have disastrous consequences.

Role of Resistance Test Equipment Manufacturers

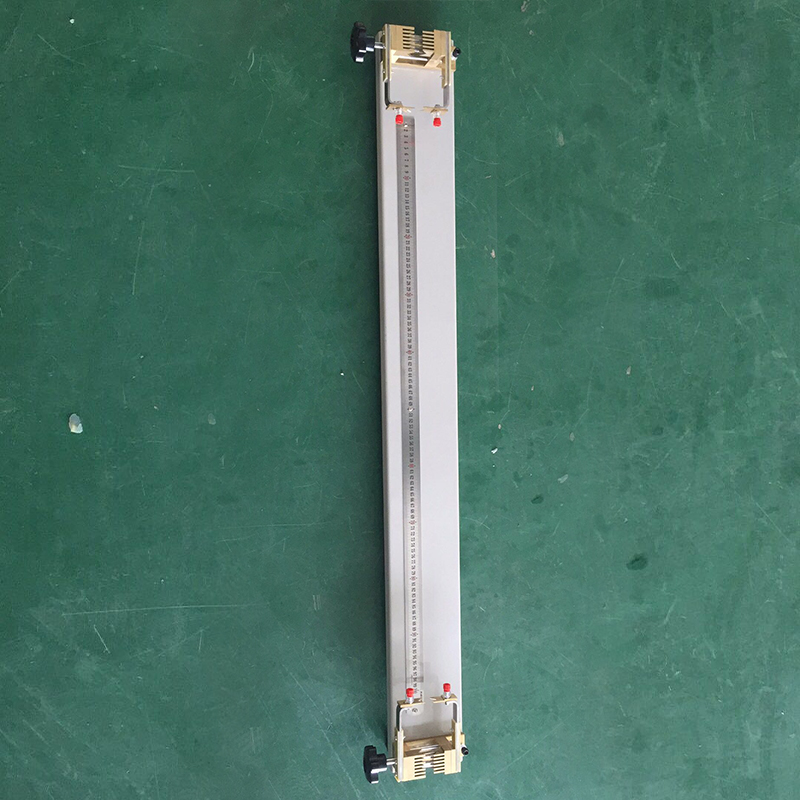

Resistance test equipment manufacturers play a crucial role in developing and refining the tools necessary for these evaluations. They produce a variety of testing devices tailored for specific applications, such as insulation resistance testers, earth resistance testers, and bonding testers. Each of these tools helps technicians effectively assess electrical safety and compliance.

resistance test equipment manufacturer

1. Innovation and Technology One of the significant contributions of resistance test equipment manufacturers is their commitment to innovation. In recent years, there have been significant advances in technology that have enhanced the functionality and accuracy of testing equipment. Modern resistance testers are equipped with digital displays, automatic ranging, and built-in memory for storing test results. This technology not only improves accuracy but also makes it easier for technicians to conduct tests quickly and efficiently.

2. Compliance with Standards Electrical safety standards are continually evolving, and resistance test equipment manufacturers are crucial in ensuring their products meet these standards. For instance, the International Electrotechnical Commission (IEC) and the National Electrical Manufacturers Association (NEMA) set rigorous guidelines for electrical testing tools. Manufacturers must ensure their products are compliant, making adherence to these standards easier for end users.

3. Training and Support Beyond just manufacturing equipment, many resistance test equipment manufacturers offer training and support services. Proper training is essential for technicians to expertly use the tools and accurately interpret the results. Manufacturers often provide workshops, online tutorials, and customer support to guide users effectively.

4. Customized Solutions Different industries have different testing needs. Resistance test equipment manufacturers often offer customized solutions tailored to specific requirements. Whether it’s a high-voltage environment or specialized equipment for mining, manufacturers can produce bespoke tools that meet niche applications.

Conclusion

The importance of resistance test equipment manufacturers in ensuring electrical safety cannot be overlooked. They provide not only the tools necessary for effective testing but also the innovation, training, and support to ensure these tools are used correctly. As electrical systems become more complex and the demand for safety and efficiency increases, the role of these manufacturers will only continue to grow. With their commitment to quality and compliance, they help pave the way for safer electrical installations across all sectors.

Investing in reliable resistance testing equipment is crucial for any organization involved in electrical work. In doing so, businesses protect their employees, infrastructure, and reputation while contributing to a safer work environment for all.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy