Top Manufacturers of Cable Aging Ovens for Reliable Performance and Durability Testing in Industries

Cable Aging Oven Manufacturers An Overview of the Industry

As the demand for high-quality electrical components continues to grow, so does the importance of testing and ensuring the reliability of these components. One critical aspect of this testing is the aging process, which simulates the long-term effects of heat and environmental factors on materials used in cables and other electrical products. Cable aging ovens are essential tools in this process, and manufacturers of these ovens play a pivotal role in the electrical and electronics industry.

Understanding Cable Aging

Cable aging refers to the deterioration that occurs in cables and electrical components over time due to environmental factors like temperature, humidity, and ultraviolet (UV) exposure. This aging process can lead to failures, reducing the overall lifespan of electrical products. Therefore, manufacturers must rigorously test their products to ensure they meet safety and performance standards.

This is where cable aging ovens come into play. These specialized ovens provide controlled thermal environments to accelerate the aging process of cables, allowing manufacturers to evaluate their long-term durability efficiently. By exposing cables to elevated temperatures, moisture, and other controlled variables, manufacturers can predict how cables will perform under actual service conditions.

The Role of Cable Aging Oven Manufacturers

Cable aging oven manufacturers design and produce these crucial testing devices with various features to meet the specific needs of the industry. These manufacturers are constantly innovating, incorporating advanced technologies to enhance the efficiency and accuracy of their ovens. Some key features that distinguish high-quality cable aging ovens include

1. Temperature Control High-precision temperature regulation is vital for ensuring consistent results. Leading manufacturers employ cutting-edge heating elements and control systems that maintain stable temperatures throughout the aging process.

2. Humidity Control Many aging tests require specific humidity levels alongside temperature control. Manufacturers often include humidification systems that allow for precise adjustments to moisture levels, simulating various environmental conditions.

cable aging oven manufacturers

3. Safety Features Given the risks involved in high-temperature operations, safety is a paramount concern for aging oven manufacturers. Features such as automatic shut-off, over-temperature alarms, and robust construction materials are standard in high-quality ovens.

4. Customizability Different manufacturers and industries have unique requirements. The best cable aging oven manufacturers offer customizable solutions, allowing clients to tailor the equipment to their specific testing needs.

5. Data Logging Modern aging ovens often come equipped with data logging capabilities, enabling manufacturers to track performance over time. This data is invaluable for compliance with industry standards and for optimizing product design.

Market Trends and Future Directions

The market for cable aging ovens is influenced by several factors, including the rapid advancement of technology in the electrical sector, the growth of renewable energy, and increased regulatory standards. As new materials and technologies emerge, the need for rigorous testing methods becomes even more critical.

Manufacturers are increasingly focusing on automation and digitalization to streamline operations and enhance data management. The integration of IoT (Internet of Things) technologies allows real-time monitoring of aging tests, leading to more efficient quality control processes.

Moreover, as sustainability becomes a focus in manufacturing, environmentally friendly practices are gaining traction. Cable aging oven manufacturers are expected to adopt energy-efficient technologies and sustainable materials in their products to align with global sustainability goals.

Conclusion

Cable aging ovens are a critical element in the quality assurance processes for cable manufacturing. As manufacturers continue to innovate and adapt to changing industry demands, the role of cable aging oven manufacturers will remain significant. By providing advanced, reliable testing solutions, these manufacturers help ensure the safety, reliability, and longevity of cable products, ultimately contributing to the progression of the electrical and electronics industry.

-

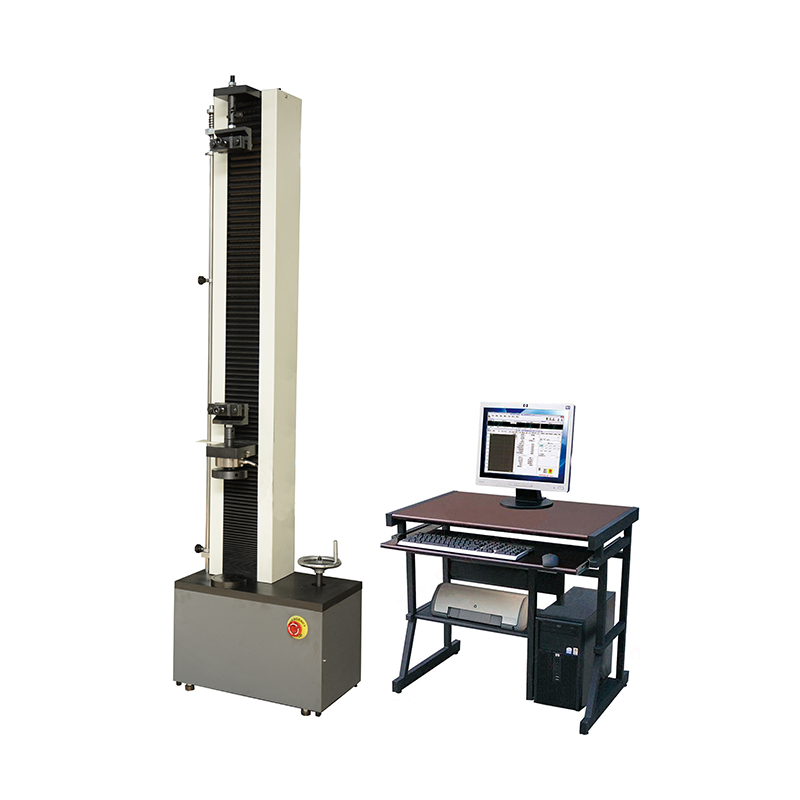

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy