automatic measuring imager

Automatic Measuring Imager Revolutionizing Measurement Techniques

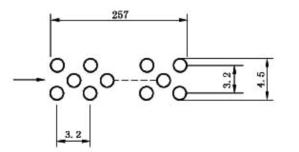

In recent years, the landscape of measurement technology has witnessed a significant transformation with the advent of automatic measuring imagers. These sophisticated devices seamlessly combine advanced imaging technology with automated measurement capabilities, thereby enhancing accuracy, efficiency, and versatility across various applications.

An automatic measuring imager is designed to capture images and extract data for precise measurements, often in real-time. Unlike traditional measurement techniques, which may rely heavily on manual input and interpretation, automatic imagers utilize advanced algorithms and artificial intelligence (AI) to process images and perform measurements with minimal human intervention. This not only speeds up the measurement process but also reduces the likelihood of human error, making it an invaluable tool in industries that demand high precision.

One of the primary advantages of automatic measuring imagers is their versatility. These instruments can be employed in various fields, ranging from manufacturing and construction to healthcare and agriculture. In manufacturing, for instance, automatic measuring imagers can inspect components for dimensional accuracy and surface defects, ensuring that products meet stringent quality standards. In healthcare, they play a crucial role in non-invasive diagnostics, where imaging technologies can measure physical attributes and anomalies without the need for invasive procedures.

The technology behind automatic measuring imagers typically involves high-resolution cameras coupled with sophisticated software that can interpret images and extract useful data. Many modern systems leverage machine learning techniques to improve their ability to discern between acceptable and unacceptable measurements over time. This adaptability means that as more data is collected, the system becomes increasingly effective at identifying patterns and anomalies.

automatic measuring imager

Moreover, automatic measuring imagers contribute significantly to the efficiency of workflow processes. By automating measurement tasks, organizations can allocate their human resources to other critical areas, thereby optimizing productivity. For example, in manufacturing, the time saved in measurement and inspection can lead to faster production cycles and reduced costs, giving companies a competitive edge in a fast-paced market.

Despite their numerous advantages, the implementation of automatic measuring imagers is not without challenges. The initial investment in technology can be substantial, and organizations must also consider the training required for staff to effectively operate and maintain these systems. Furthermore, integration with existing technologies and workflows can present hurdles that need to be addressed for seamless operation.

Looking ahead, the future of automatic measuring imagers appears promising. As technology continues to advance, we can expect further innovations in imaging capabilities, processing speed, and data analysis. With the integration of IoT (Internet of Things) technologies, automatic measuring imagers could soon facilitate remote monitoring and control, providing real-time data across different sites and applications.

In conclusion, automatic measuring imagers represent a significant leap forward in measurement technology. Their ability to deliver accurate, efficient, and versatile solutions positions them as indispensable tools in various industries. As technological advancements continue to shape their development, we can anticipate an even broader impact on how measurements are conducted in the future, leading to improved standards and practices across the board.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy