Jan . 10, 2025 09:17

Back to list

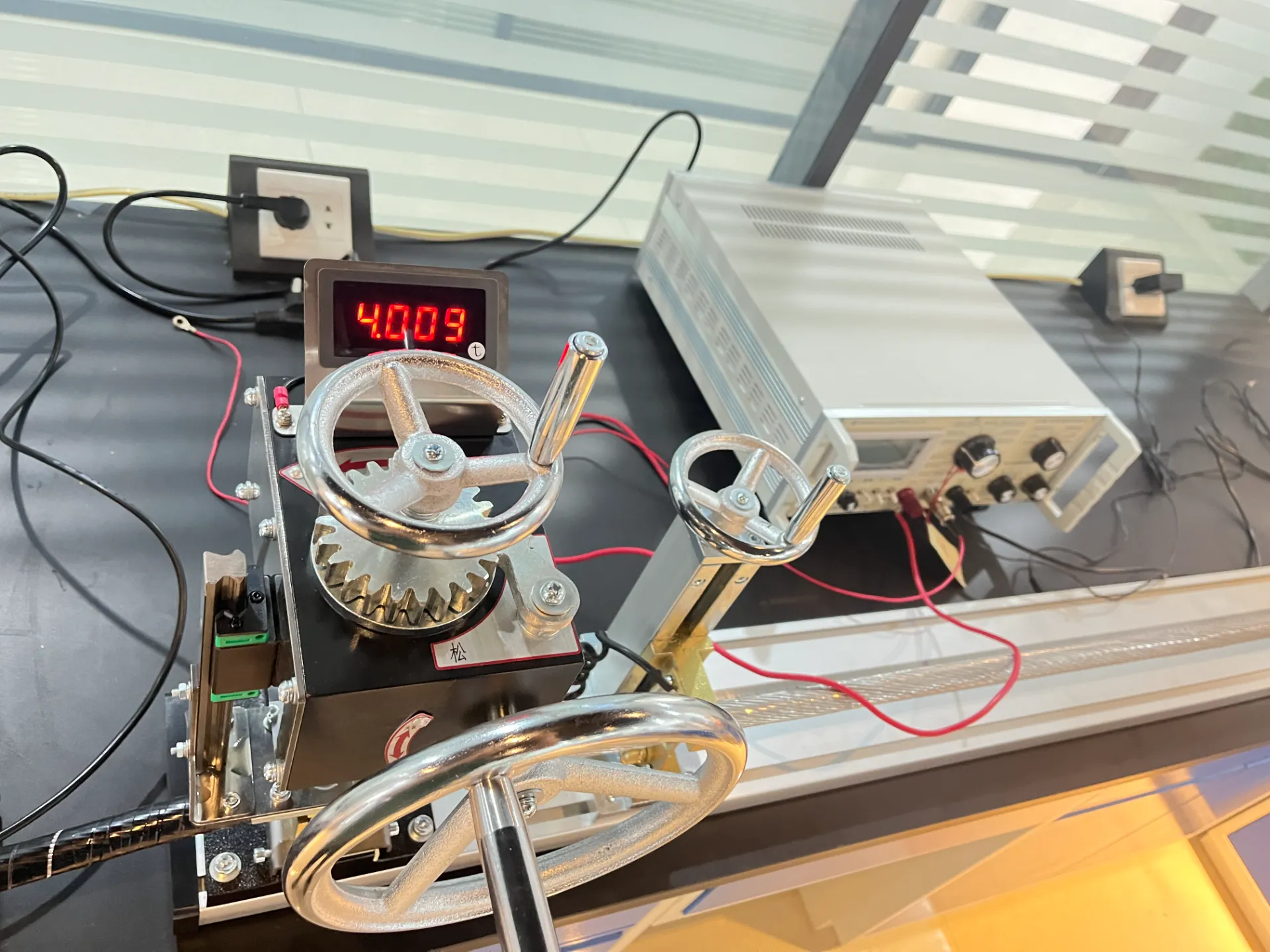

FY-NHZ Cable Fire Resistance Characteristics Test Equipment(Mass Flow Controller)

Cable flexibility test machines are crucial in ensuring the integrity and performance of cables used across various industries. Understanding the significance of these machines can greatly enhance your knowledge and decision-making when it comes to selecting the right equipment for cable testing purposes.

Authoritativeness in cable flexibility testing machinery comes from working with manufacturers and brands known for their innovation and reliability. Brands that have a long-standing reputation in producing test equipment often feature extensive warranties and service packages. For example, leading manufacturers provide comprehensive user training and technical support, ensuring that their clients can fully leverage the machine's capabilities. Furthermore, partnerships with academic institutions for testing and validation offer additional layers of credibility to a brand’s offerings, reinforcing their status as industry leaders. Trustworthiness is pivotal when investing in cable flexibility test machines. Ensuring a machine's durability and accuracy significantly impacts its reliability. Machines with robust design, built from high-quality materials, and featuring precision sensors for accurate data collection, are considered highly trustworthy. In addition, look for testimonials and reviews from other industry professionals who have used the machines effectively in high-demand scenarios. Trust is further built by the machine's track record in diverse environments, such as its performance in both high and low temperature or humidity conditions, which are often critical factors in cable testing. In conclusion, cable flexibility test machines are fundamental tools in the lifecycle assessment of cable products. Through personal experience, technical expertise, authoritative manufacturing, and trustworthy operation, these machines provide essential insights that drive product innovation and reliability. Whether you are an R&D engineer in search of a precise test setup or a quality assurance manager aiming to maintain high product standards, recognizing these aspects will aid in making informed decisions that align with both industry expectations and consumer demands.

Authoritativeness in cable flexibility testing machinery comes from working with manufacturers and brands known for their innovation and reliability. Brands that have a long-standing reputation in producing test equipment often feature extensive warranties and service packages. For example, leading manufacturers provide comprehensive user training and technical support, ensuring that their clients can fully leverage the machine's capabilities. Furthermore, partnerships with academic institutions for testing and validation offer additional layers of credibility to a brand’s offerings, reinforcing their status as industry leaders. Trustworthiness is pivotal when investing in cable flexibility test machines. Ensuring a machine's durability and accuracy significantly impacts its reliability. Machines with robust design, built from high-quality materials, and featuring precision sensors for accurate data collection, are considered highly trustworthy. In addition, look for testimonials and reviews from other industry professionals who have used the machines effectively in high-demand scenarios. Trust is further built by the machine's track record in diverse environments, such as its performance in both high and low temperature or humidity conditions, which are often critical factors in cable testing. In conclusion, cable flexibility test machines are fundamental tools in the lifecycle assessment of cable products. Through personal experience, technical expertise, authoritative manufacturing, and trustworthy operation, these machines provide essential insights that drive product innovation and reliability. Whether you are an R&D engineer in search of a precise test setup or a quality assurance manager aiming to maintain high product standards, recognizing these aspects will aid in making informed decisions that align with both industry expectations and consumer demands.

Next:

Latest news

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy