Tensile Testing Machines Following ASTM D412 Standards from Reliable Factories

Understanding ASTM D412 The Standard for Tensile Testing of Elastomeric Materials

Tensile testing is a critical aspect in the field of materials science, particularly when it comes to evaluating elastomeric materials, such as rubber. Among the various standards that guide this process, ASTM D412 stands out as a key reference point. This standard provides a systematic method for determining the tensile properties of rubber materials, ensuring that manufacturers and researchers maintain consistency and accuracy in their testing procedures.

What is ASTM D412?

ASTM D412 is a standard test method developed by the American Society for Testing and Materials (ASTM) for the tensile properties of elastomeric materials. The standard outlines the procedures for preparing test specimens, conducting the tensile test, and calculating results, such as elongation at break and tensile strength. The designation D412 specifically refers to the test for vulcanized rubber and thermoplastic elastomers, which are widely used in various applications across industries, including automotive, aerospace, and consumer goods.

Importance of Tensile Testing

Tensile testing serves several critical functions in the evaluation of elastomeric materials. It provides insight into the material's strength, elasticity, and ultimate durability, which are essential factors in determining how a material will perform in practical applications. For instance, in automotive applications, a rubber seal needs to withstand stress and strain while maintaining its shape. The ability to measure these characteristics through ASTM D412 helps manufacturers ensure that their products will endure the mechanical demands placed upon them.

The Testing Process

The ASTM D412 testing process consists of several steps. First, appropriate specimens must be prepared. The standard specifies the shape and dimensions of the samples, along with the number needed for reliable statistical analysis. Next, the specimens are conditioned under specified temperatures and humidity levels to eliminate variations that may affect the results.

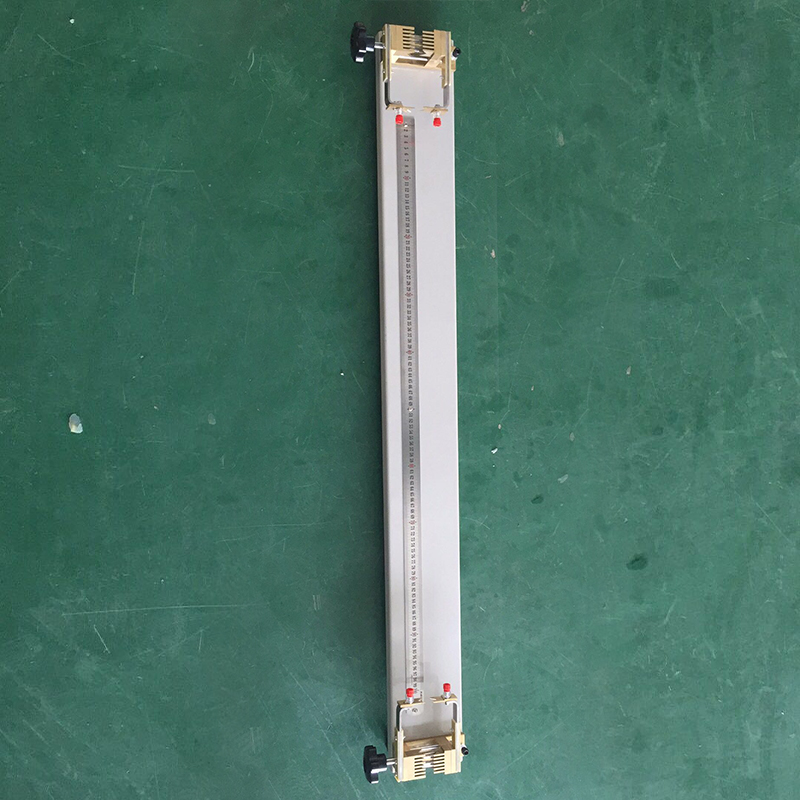

tensile tester astm d412 factories

Once the specimens are prepared, they are placed in a tensile tester – a machine that elongates the sample at a controlled rate until it fails. During the test, various parameters are recorded, including the force applied and the corresponding elongation. The data collected allows for the calculation of key tensile properties, including

1. Tensile Strength The maximum stress that a material can withstand while being stretched or pulled. 2. Elongation at Break The amount of stretch a material can endure before breaking, expressed as a percentage of its original length. 3. Modulus of Elasticity A measure of the material's stiffness, calculated as the slope of the stress-strain curve within the elastic limit.

Compliance and Quality Assurance

Factories that produce elastomeric materials often implement ASTM D412 as part of their quality assurance processes. By consistently adhering to this standard, manufacturers can ensure that their products meet industry specifications. Compliance not only boosts product reliability but also builds trust with customers and stakeholders who rely on these materials.

Moreover, adherence to national and international standards like ASTM D412 can give companies a competitive edge in the market. It demonstrates a commitment to quality and safety, which is essential in maintaining a robust reputation in any industry. In a world where consumers are increasingly conscious of product quality, the importance of meeting standards cannot be overstated.

Conclusion

In conclusion, the ASTM D412 standard is pivotal in the tensile testing of elastomeric materials, providing a systematic approach to evaluating their mechanical properties. The ability to obtain consistent and reliable data through this standard is crucial for manufacturers aiming to produce high-quality products. As industries continue to innovate and push the boundaries of material application, standards like ASTM D412 will remain foundational to ensuring that elastomeric materials meet the rigorous demands of modern applications. By understanding and implementing this standard, factories can optimize their production processes and enhance the quality and performance of their products.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy