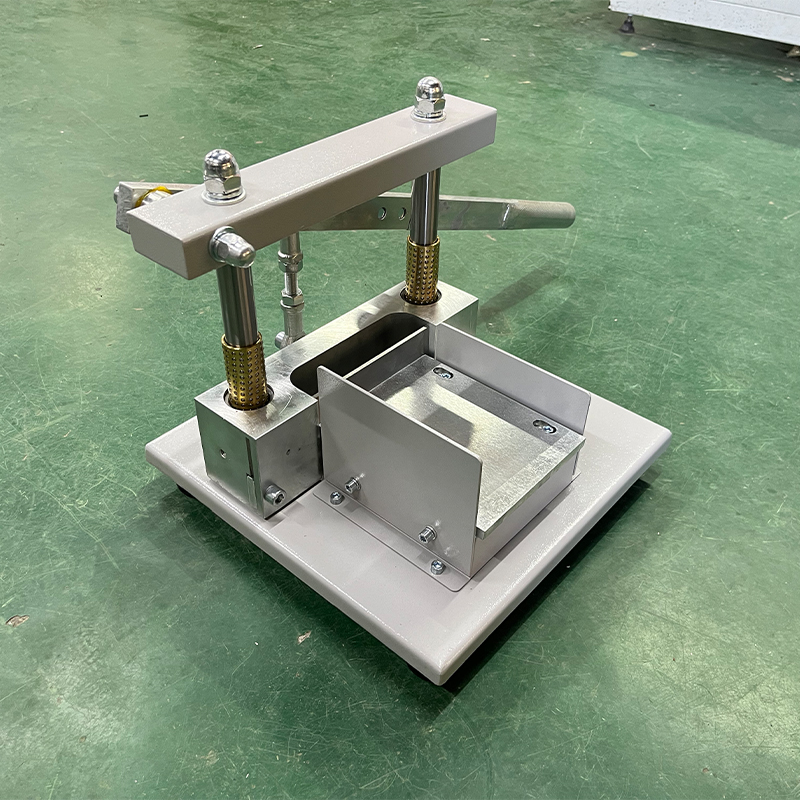

china cable cut machine

Understanding the Cable Cut Machine A Vital Tool for the Chinese Manufacturing Sector

In the fast-evolving landscape of manufacturing technology, efficiency and precision are paramount. Among the myriad of machines that facilitate these goals, the cable cut machine has gained significant importance, especially within the context of China's booming manufacturing industry. This article delves into the significance, functionality, and advancements associated with cable cut machines, reflecting on their relevance in the modern manufacturing environment.

The Role of Cable Cut Machines

Cable cut machines are designed to automate the process of cutting various types of cables, including electrical, communication, and fiber optic cables. These machines play a critical role in ensuring that cables are cut to precise lengths, which is essential for maintaining quality standards in manufacturing. In China, a country known for its vast production capabilities, cable cut machines are indispensable in a variety of industries, from automotive to telecommunications.

The automation of cable cutting not only enhances efficiency but also reduces human error, a common issue in manual cutting processes. By ensuring precise measurements and consistent quality, cable cut machines help manufacturers minimize waste and optimize their production lines. This efficiency can lead to significant cost savings, thereby enhancing competitiveness in an increasingly globalized market.

Key Features and Technology

Modern cable cut machines are equipped with advanced technology that boosts their functionality. Most machines today feature programmable logic controllers (PLCs) that allow for easy input of cutting specifications. Operators can input numerous parameters, such as cable diameter, length, and type, enabling the machine to adjust accordingly for different jobs.

Moreover, many machines incorporate sensors and cutting blades designed to handle a variety of materials, including copper, aluminum, and plastic insulation. This versatility is essential for manufacturers that work with multiple cable types and require a machine that can adapt to diverse production needs.

china cable cut machine

In recent years, the integration of Industry 4.0 technologies has further advanced cable cut machines. Features such as IoT connectivity enable real-time monitoring and data collection, allowing manufacturers to track performance, predict maintenance needs, and improve overall operational efficiency.

Impact on the Chinese Manufacturing Industry

The rise of cable cut machines is emblematic of the broader technological advancements within the Chinese manufacturing sector. As the country shifts towards high-tech production, the demand for such machines is likely to grow. Manufacturers not only seek efficiency but also aim to enhance their sustainability efforts. Automated processes can reduce energy consumption and material waste, contributing to greener manufacturing practices.

China's government initiatives to promote modern manufacturing and innovation further bolster this trend. Investments in smart manufacturing and advanced automation are paving the way for more companies to adopt sophisticated machinery, including cable cut machines.

Conclusion

The cable cut machine represents a convergence of precision, efficiency, and technological advancement that is essential in today's manufacturing landscape. In the context of China's robust industrial sector, these machines are crucial for maintaining competitiveness and achieving operational excellence. As manufacturers strive for higher productivity and improved sustainability, the role of cable cut machines will undoubtedly expand.

Understanding this technology is not just about recognizing a useful tool; it's about appreciating its impact on the future of manufacturing in China and beyond. As we move forward, innovations in cable cutting technology will likely play a significant role in shaping the efficiency and quality of production processes, reinforcing the idea that advancements in machinery are there to meet the demands of an ever-changing market.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy