Supplier of Digital Profile Projectors for Precision Measurement Solutions

Digital Profile Projectors The Future of Precision Measurement

In the realm of manufacturing and quality control, precision is key. Whether it’s inspecting complex mechanical parts or ensuring the accuracy of intricate designs, the tools we use play a pivotal role. Among these tools, digital profile projectors have become indispensable. As technology continues to evolve, so do the capabilities of these devices, offering manufacturers and quality control experts a way to measure and inspect parts with unprecedented accuracy and efficiency.

Understanding Digital Profile Projectors

Digital profile projectors, also known as optical comparators, are sophisticated instruments used to project a magnified silhouette of an object onto a screen. This image allows operators to compare the part's profile against predetermined standards. The advent of digital technology has revolutionized these devices, incorporating advanced features such as digital displays, automated measurement capabilities, and enhanced image processing technologies.

Key Features of Modern Digital Profile Projectors

1. High Precision Measurements Modern digital profile projectors come equipped with high-resolution optics and precise measurement systems. This enables users to achieve accurate measurements down to microns. This precision is crucial in industries where mechanical parts must adhere to strict tolerances.

2. User-Friendly Interfaces The interface of digital profile projectors has seen significant improvements. With touchscreen controls and intuitive software, operators can navigate through menus easily, making the measurement process seamless and straightforward. This ease of use reduces operator error and speeds up the inspection process.

3. Data Management Capabilities Many advanced profile projectors offer data management features that allow users to save measurements, generate reports, and even interface with other quality control systems. This integration is vital in modern manufacturing environments where data-driven decision-making is paramount.

4. Versatility Digital profile projectors are not limited to one type of measurement. They can be used for a variety of applications, including inspecting machined parts, measuring intricate patterns, and even verifying the dimensions of components in medical devices and aerospace applications.

The Benefits of Using Digital Profile Projectors

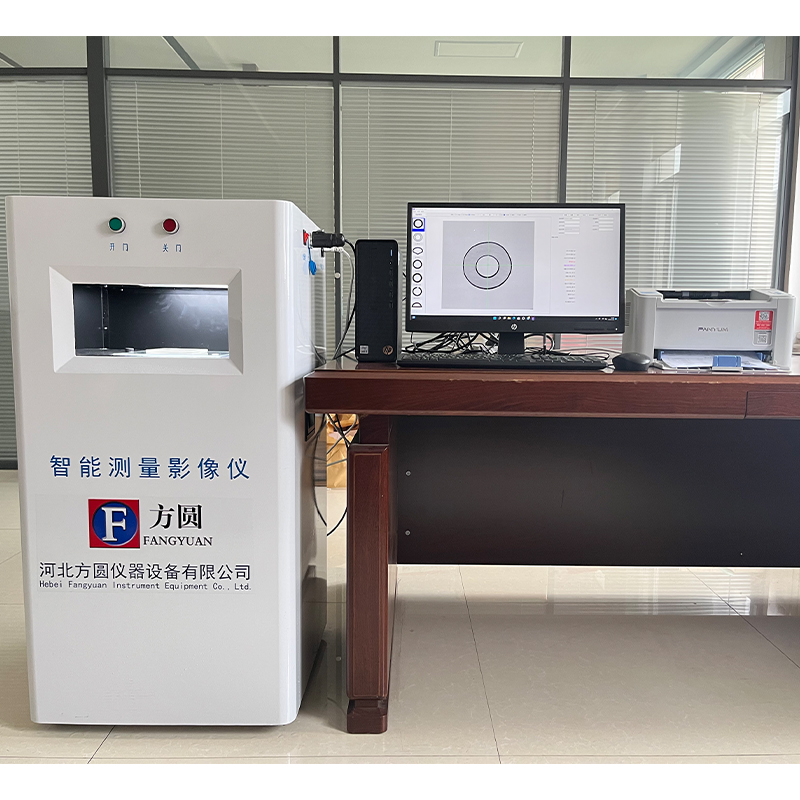

digital profile projectors supplier

1. Increased Efficiency The automation and speed of digital profile projectors significantly reduce the time required for measurement and inspection. Operators can perform measurements much quicker than with traditional methods, which translates to higher productivity levels on the manufacturing floor.

2. Improved Accuracy The digital nature of these projectors minimizes human error inherent in manual measurements. With automated processes and high-definition imaging, the accuracy of each measurement increases, leading to better quality control.

3. Cost-Effectiveness Investing in digital profile projectors can lead to long-term cost savings for companies. By ensuring that parts are manufactured within specifications, manufacturers can reduce waste, lower rework costs, and enhance customer satisfaction by delivering high-quality products consistently.

4. Enhanced Collaboration With advanced reporting and data sharing capabilities, teams can easily share measurement results with other departments, fostering collaboration between design, production, and quality assurance teams.

Choosing the Right Supplier

When it comes to procuring digital profile projectors, selecting the right supplier is critical. Look for suppliers with a proven track record in the industry, offering robust support, calibration services, and training. Moreover, consider the range of options available, as different projects may require different solutions.

A good supplier will not only provide you with high-quality equipment but also help you integrate these tools into your existing processes. They should offer comprehensive training programs to ensure that your team can maximize the capabilities of the projectors, thereby realizing the full benefits of the technology.

Conclusion

Digital profile projectors represent a significant leap forward in the field of precision measurement and inspection. With their advanced features, user-friendly designs, and capabilities for data integration, these instruments are redefining quality control processes across various industries. As the demand for precision increases in manufacturing, investing in digital profile projectors will undoubtedly lead to enhanced efficiency, reduced costs, and ultimately, greater customer satisfaction. Choosing the right supplier will not only ensure you receive a quality product but also provide ongoing support as you navigate the future of precision measurement.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy