UV Irradiation Crosslinking Machine Manufacturer | High-Quality Crosslinking Solutions

The Role of UV Irradiation Crosslinking Machines in Manufacturing

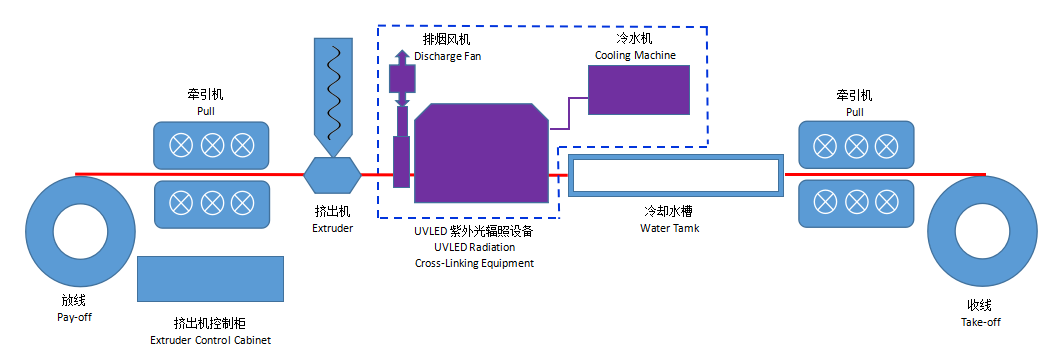

In the realm of modern manufacturing, the emergence of UV irradiation crosslinking machines has significantly transformed the way various materials are processed. This innovative technology utilizes ultraviolet (UV) light to initiate crosslinking reactions in polymers and other materials, enhancing their properties and durability. Factories equipped with these machines have reported substantial improvements in efficiency and product quality.

UV irradiation crosslinking is a process where UV light interacts with certain chemical compounds, leading to the formation of links between polymer chains

. This results in a material that exhibits increased strength, resistance to solvents, heat, and wear, making it suitable for a wide range of applications. Common uses of crosslinked materials include coatings, adhesives, inks, and various plastic products.One of the primary benefits of utilizing UV irradiation in manufacturing is the speed of the crosslinking process. Traditional curing methods can take hours or even days, while UV crosslinking can achieve the desired results in mere seconds. This drastically reduces production times and enhances the overall efficiency of factories. Moreover, UV technology minimizes the need for solvents and other harmful chemicals, aligning with modern environmental regulations and sustainable practices.

uv irradiation crosslinking machine factories

Factories focusing on UV irradiation crosslinking machines are increasingly investing in advanced technology. This includes automated systems that ensure consistent exposure to UV light, enhancing product uniformity and quality control. As industries evolve, the demand for high-performance materials continues to rise, and the ability to swiftly produce crosslinked products is a competitive advantage.

Moreover, UV crosslinking machines are versatile and can be adapted to various industries, including automotive, packaging, and electronics. This adaptability allows manufacturers to diversify their product lines and meet specific customer needs without extensive retooling.

In conclusion, UV irradiation crosslinking machines are indispensable in contemporary manufacturing. They not only streamline production processes but also contribute to the creation of superior products. As factories continue to embrace this technology, they pave the way for enhanced material properties, faster turnaround times, and a more sustainable industrial future. The ongoing innovation in UV curing technologies is poised to further revolutionize the manufacturing landscape, making it an exciting area to watch in the coming years.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy