Factory for Testing Machines for Wires and Cables Manufacturing Solutions

An Overview of Wire and Cable Testing Machine Manufacturing

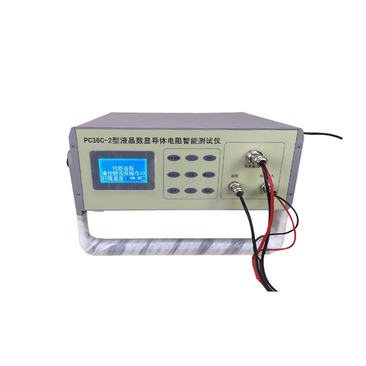

In the modern world of electrical engineering, the integrity and performance of wires and cables are paramount. This is where wire and cable testing machines come into play. These sophisticated devices are essential for ensuring that electrical conductors meet industry standards and can operate safely and efficiently in a variety of applications. The manufacturing of these testing machines involves a complex interplay of technology, precision engineering, and stringent quality control.

Wire and cable testing machines are designed to assess several critical parameters, including insulation resistance, dielectric strength, tensile strength, and elongation. Each of these factors is crucial to the performance and safety of the cables used in everything from household appliances to industrial machinery. A failure in any of these areas can result in significant safety hazards, leading to potential downtime, financial loss, or worse, catastrophic failures.

An Overview of Wire and Cable Testing Machine Manufacturing

Once a design is finalized, the next phase is production. Manufacturers typically utilize high-grade materials such as steel and aluminum for the frame, ensuring durability and stability during testing. The electronic components are sourced from reputable suppliers to guarantee accuracy and consistency. Each machine is assembled with meticulous attention to detail, as even minor misalignments can lead to erroneous testing results.

wire and cable testing machine factory

Quality assurance is a vital component of the manufacturing process. Every wire and cable testing machine undergoes a series of rigorous tests to ensure it functions correctly and meets all safety standards. These tests include calibration procedures to check the accuracy of readings, as well as stress tests to validate the machine's endurance under heavy usage. Compliance with international standards, such as ISO and IEC, is essential, as these certifications reassure customers about the quality and reliability of the testing machines.

The final stage in the manufacturing process is packaging and delivery. Testing machines are carefully packaged to prevent damage during transportation and are often accompanied by detailed manuals to guide users in operation and maintenance. Manufacturers also provide training programs for customers to ensure they can use the machines effectively and get the most out of their capabilities.

As technology continues to evolve, the wire and cable testing machine industry is witnessing advancements that enhance testing accuracy and efficiency. Automation and digital integration are becoming increasingly common, allowing for real-time monitoring and data analytics during the testing process. These innovations not only streamline operations but also provide valuable insights into cable performance, facilitating predictive maintenance and improving overall safety.

In conclusion, the manufacturing of wire and cable testing machines is a complex process that demands precision, expertise, and commitment to quality. These machines play a vital role in ensuring the safety and reliability of electrical systems across various industries. As technology advances, so will the capabilities of these testing machines, making them even more essential in our increasingly electrified world. The ongoing development in this field promises not only to elevate safety standards but also to enhance the performance and longevity of electrical setups globally.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy