cable vertical flame test machine

Cable Vertical Flame Test Machine Ensuring Safety and Compliance in Cable Manufacturing

In the ever-evolving world of cable manufacturing, safety and compliance have become paramount concerns. As industries expand and technologies advance, the demand for reliable and flame-resistant cables is greater than ever. One crucial tool in ensuring the adherence to safety standards is the Cable Vertical Flame Test Machine. This specialized equipment serves as an essential component in the testing and certification of various types of cables, particularly electrical cables, to ensure their resistance to flames and heat.

Understanding the Cable Vertical Flame Test Machine

The Cable Vertical Flame Test Machine is a device specifically designed to evaluate the flammability of electrical cables and their components. This testing method is vital for determining how cables will behave in the event of a fire. By simulating real-world conditions, manufacturers can identify potential hazards and enhance the safety features of their products.

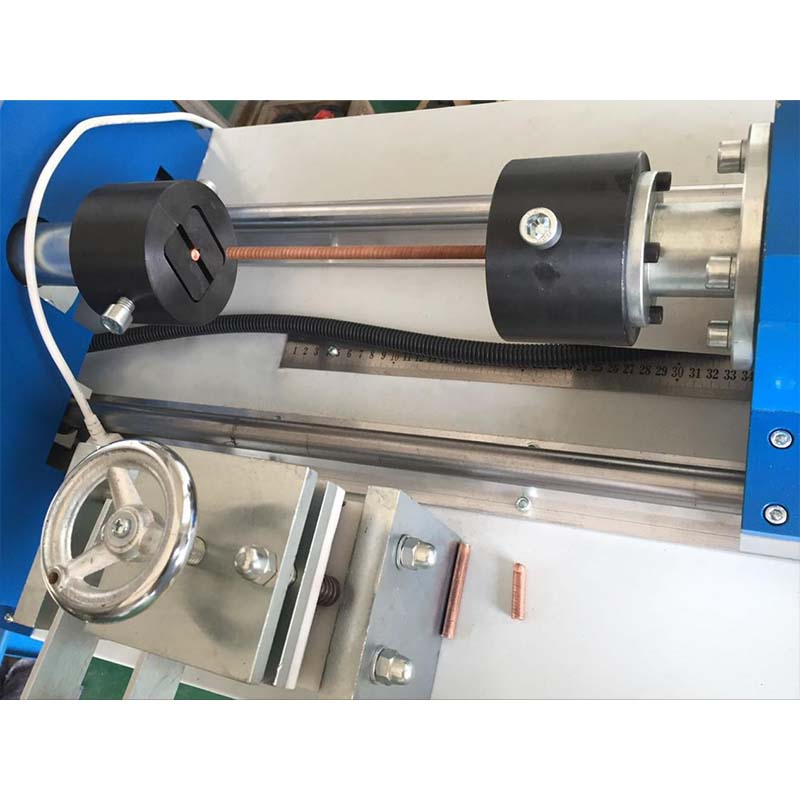

The machine typically consists of a vertical test chamber where the cable specimens are placed. A controlled flame source is applied to the cable under specified conditions, allowing for the measurement of flame spread, burning duration, and other critical parameters. The results obtained from these tests are vital in determining compliance with international safety standards, such as UL, IEC, and BS, which heavily influence marketability and safety protocols.

Importance of Flame Testing

Flame testing is not just a regulatory requirement; it is a crucial aspect of product safety. In the event of a fire, cables that do not adhere to rigorous flame resistance standards can contribute to the rapid spread of flames and toxic smoke, leading to severe consequences, including property damage and loss of life.

By employing a Cable Vertical Flame Test Machine, manufacturers can

cable vertical flame test machine

1. Ensure Compliance Compliance with safety regulations is mandatory in many industries. Regular testing helps companies maintain certifications that are necessary for market access. 2. Enhance Product Reputation A reputation for safety can set a manufacturer apart in a competitive market. Testing cables for flame resistance demonstrates a commitment to quality, which can attract more customers and partners. 3. Identify Design Flaws The testing process can reveal vulnerabilities, allowing engineers to make design modifications to enhance flame resistance before mass production. This proactive approach can save time and reduce costs associated with compliance failures post-production.

4. Reduce Liability In an age of increasing litigation regarding product safety, having rigorously tested cables can help manufacturers mitigate legal risks associated with fire-related incidents.

The Testing Process Key Steps

The testing process using the Cable Vertical Flame Test Machine involves several key steps

1. Sample Preparation Cable specimens are prepared according to specified dimensions and configurations. 2. Set Up the Machine Test parameters are set, including the height of the flames, flame application time, and measurement of the ambient conditions. 3. Conduct the Test The flame is applied to the cable sample, and data is collected regarding the ignition time, flame spread rate, and duration of combustion. 4. Data Analysis The collected data is analyzed to assess the performance of the cable against established safety standards. 5. Documentation and Reporting A detailed report is generated, summarizing the findings and indicating whether the cable has passed or failed the testing criteria.

Conclusion

As technology continues to advance, the importance of safety and compliance in cable manufacturing will not diminish. The Cable Vertical Flame Test Machine plays a critical role in ensuring that cables meet necessary flame resistance standards. By investing in such testing machinery, manufacturers not only comply with regulations but also contribute to a safer environment for users. Ultimately, the desire for high-quality, flame-resistant cables will continue to drive the need for rigorous testing and innovative solutions in the manufacturing process. This commitment to safety not only protects the users but also fortifies the reputation and success of manufacturers in the global market.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy