Feb . 13, 2025 20:37

Back to list

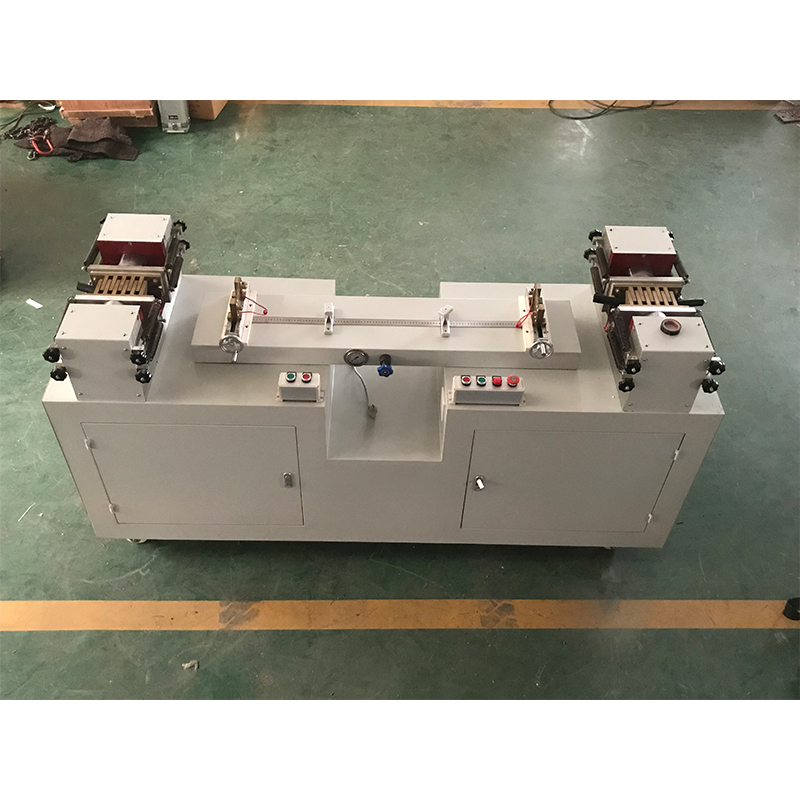

FY-NHZ Cable Fire Resistance Characteristics Test Equipment(Mass Flow Controller)

Conducting conductor resistance tests is a crucial procedure for manufacturers and professionals in the electrical industry, particularly when dealing with China's vast market. With the country's booming infrastructural developments, ensuring safety and efficiency in electrical components is paramount. Understanding this process from the perspective of experience, expertise, authoritativeness, and trustworthiness reveals foundational insights into its significance.

Authoritative figures in this field include industry regulatory bodies and renowned institutes that ensure such tests comply with international and national standards. In China, organizations like the China Electrical Equipment Industry Association (CEEIA) provide guidelines that all manufacturers must adhere to, ensuring uniformity and safety. Publications and seminars funded by these authoritative bodies offer a wealth of validated knowledge, further helping manufacturers align their practices with set standards while advancing innovation in their processes. Trustworthiness is paramount when conducting these tests, as results dictate product viability and consumer safety. Reputable testing laboratories in China undergo rigorous accreditation to guarantee their conformity with industry requirements. These institutions employ experts who regularly calibrate their instruments, ensuring precise and trustworthy readings. Moreover, detailed documentation of testing procedures and results bolsters transparency and accountability, reinforcing consumer confidence in these products. In conclusion, conductor resistance tests are indispensable in maintaining safety, performance, and compliance in China’s electrical industry. Drawing on the experiences of field professionals, leveraging specialized expertise, adhering to authoritative standards, and maintaining trustworthy procedures collectively fortify the process of delivering superior electrical conductors. This holistic approach not only uplifts the quality standard within China but also underpins its position as a formidable player in the global market, where quality assurance aligns with international best practices.

Authoritative figures in this field include industry regulatory bodies and renowned institutes that ensure such tests comply with international and national standards. In China, organizations like the China Electrical Equipment Industry Association (CEEIA) provide guidelines that all manufacturers must adhere to, ensuring uniformity and safety. Publications and seminars funded by these authoritative bodies offer a wealth of validated knowledge, further helping manufacturers align their practices with set standards while advancing innovation in their processes. Trustworthiness is paramount when conducting these tests, as results dictate product viability and consumer safety. Reputable testing laboratories in China undergo rigorous accreditation to guarantee their conformity with industry requirements. These institutions employ experts who regularly calibrate their instruments, ensuring precise and trustworthy readings. Moreover, detailed documentation of testing procedures and results bolsters transparency and accountability, reinforcing consumer confidence in these products. In conclusion, conductor resistance tests are indispensable in maintaining safety, performance, and compliance in China’s electrical industry. Drawing on the experiences of field professionals, leveraging specialized expertise, adhering to authoritative standards, and maintaining trustworthy procedures collectively fortify the process of delivering superior electrical conductors. This holistic approach not only uplifts the quality standard within China but also underpins its position as a formidable player in the global market, where quality assurance aligns with international best practices.

Latest news

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy