manual tensile tester factories

Exploring Manual Tensile Tester Factories A Comprehensive Overview

In the realm of materials testing, the manual tensile tester plays a critical role in determining the mechanical properties of various materials. With the increasing demand for high-quality materials in industries such as construction, automotive, and aerospace, the relevance of manual tensile testers has surged. This article delves into the operational aspects of manual tensile tester factories, emphasizing their significance in materials science and engineering.

Understanding Manual Tensile Testing

Tensile testing is a method used to evaluate the strength and ductility of materials. This process involves applying a controlled pulling force to a specimen until it deforms or breaks, allowing engineers to measure properties such as tensile strength, yield strength, elongation, and reduction of area. Manual tensile testers are particularly vital in settings where precision and careful observation are essential. Unlike automated systems, manual testers provide operators with direct control over the testing procedure, ensuring that each test can be conducted according to specific parameters and material characteristics.

The Role of Manual Tensile Tester Factories

Manufacturers specializing in manual tensile testers play a pivotal part in supply chains across various industries. These factories focus on designing and producing machines that guarantee accuracy, reliability, and longevity. The primary components of these devices often include a frame, testing grips, a measuring system, and data acquisition systems. The quality of each component is fundamental to the overall performance of the tester.

A typical factory engaged in the production of manual tensile testers operates in several stages

1. Design and Prototyping Engineers and designers collaborate to create blueprints and prototypes of the manual tensile tester. This stage involves rigorous calculations and simulations to ensure the product meets industry standards and client specifications.

2. Material Selection Factories must choose high-quality materials for the construction of the testers. Steel and aluminum are commonly used due to their strength and durability. The choice of materials directly influences the performance of the device during testing.

manual tensile tester factories

3. Manufacturing The manufacturing process involves precision machining, welding, and assembly. Each component must be fabricated with accuracy to ensure that the final product functions as intended. Quality control measures are implemented at various stages to minimize defects.

4. Calibration and Testing After assembly, the testers undergo extensive calibration and functional testing. This ensures that they provide accurate measurements and can withstand the rigors of repeated use. Operators check the devices against standard benchmarks to confirm their performance.

5. Distribution Once manufactured and tested, manual tensile testers are packaged and shipped to clients around the globe. Factories must maintain strong logistics and customer service departments to ensure timely delivery and support.

The Market for Manual Tensile Testers

The global market for manual tensile testers is expanding, driven by the need for precise material testing across multiple sectors. These testers are particularly favored by laboratories, educational institutions, and small manufacturing firms that require reliable yet cost-effective testing solutions. The demand for manual testers is also fueled by increasing regulatory requirements in material quality assurance.

Moreover, factories dedicated to manual tensile testers are continually innovating. Businesses are incorporating features like digital displays, enhanced grips for various material types, and user-friendly interfaces that facilitate ease of use for operators. As technology progresses, many manual systems are also integrating with data management software, providing users with the ability to analyze and report results efficiently.

Conclusion

In summary, manual tensile tester factories are vital to the materials testing industry. They not only produce essential equipment that ensures materials meet required standards but also contribute to advancements in material science through ongoing innovation. As industries increasingly prioritize quality and compliance, the role of these factories will likely continue to grow, underscoring the importance of manual tensile testing in today's manufacturing landscape. By understanding the complexities involved in the production and operation of manual tensile testers, stakeholders can better appreciate the significance of this crucial testing equipment in ensuring the integrity and performance of materials.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

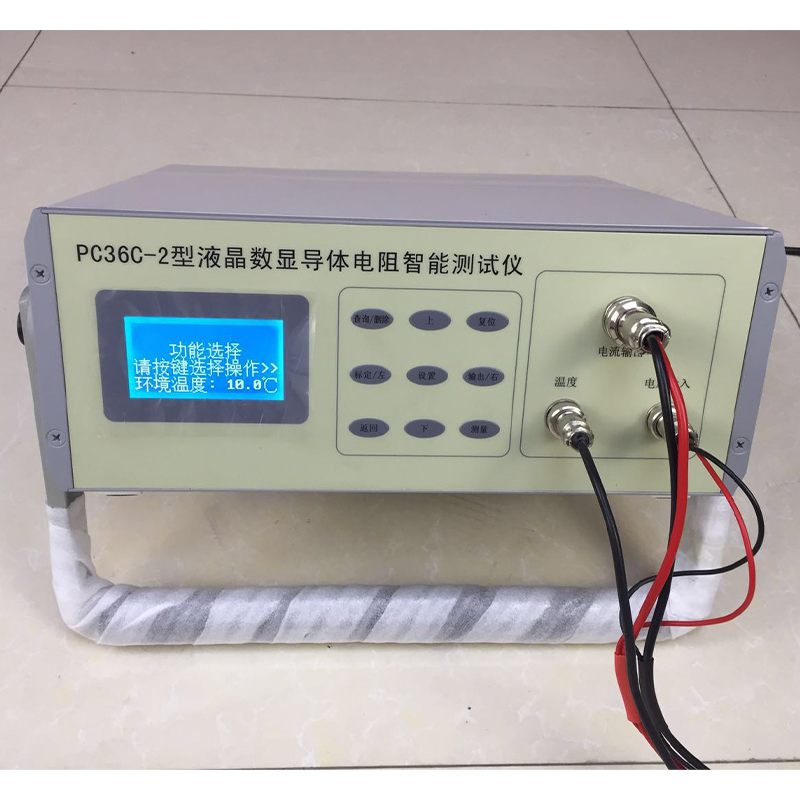

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy