cable heat pressure test

Cable Heat Pressure Test A Critical Examination of Electrical Cable Integrity

In the realm of electrical engineering, ensuring the integrity and reliability of cables is paramount for safe and efficient operation. One of the essential tests employed for this purpose is the Cable Heat Pressure Test. This procedure helps in assessing the performance characteristics of cables under simulated operational conditions, particularly focusing on thermal and mechanical stresses. Understanding the significance, methodology, and implications of this test is crucial for professionals in the field.

Importance of Cable Testing

Electrical cables are ubiquitous in modern infrastructure, powering everything from residential buildings to industrial plants. As such, they are subject to various environmental conditions and loads that can affect their performance over time. The Cable Heat Pressure Test provides valuable insights into how cables respond to high temperatures, pressure, and potential thermal degradation. By assessing the thermal properties of cables, engineers can predict their lifespan and reliability, reducing the likelihood of catastrophic failures that could have serious safety implications or lead to expensive downtimes.

Methodology of the Cable Heat Pressure Test

The Cable Heat Pressure Test involves subjecting a sample cable to controlled thermal and mechanical stress conditions. The test typically consists of the following steps

1. Preparation of Samples Cable samples are prepared according to standardized specifications to ensure uniformity in testing. This may involve cutting the cable to a standard length and ensuring that the insulation and conductor materials are intact.

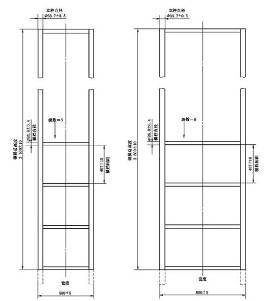

2. Setup of Testing Environment The samples are placed within a testing chamber equipped with heating elements. The environment is designed to simulate the operational conditions the cables would face in real-world applications, including variations in temperature and pressure.

3. Application of Heat The cables are subjected to a specified temperature, usually higher than the maximum operational temperature they would encounter. This step is critical, as it helps simulate severe conditions that cause thermal aging and degradation of materials.

cable heat pressure test

4. Pressure Application Concurrently with heat, pressure is applied to the cable samples. This mimics physical forces that cables might encounter due to external impacts, installations, or the weight of surrounding materials.

5. Monitoring and Data Collection During the test, the performance of the cable is monitored closely. Parameters such as temperature fluctuations, changes in resistance, and any physical deformations are recorded.

6. Post-Test Analysis Once the test concludes, a detailed analysis is conducted to assess the condition of the cable. This may involve visual inspections, electrical testing, and measurements of insulation integrity.

Implications of the Test Results

The outcomes of the Cable Heat Pressure Test provide essential information that can influence both design and maintenance practices. For instance, if a cable exhibits significant degradation or failure under heat and pressure, it may indicate that the materials used are unsuitable for specific applications. This insight allows manufacturers to revise their specifications, enhance material properties, or alter production techniques to improve overall durability.

Moreover, the test results can guide recommendations for installation practices, such as suitable protective measures or routing strategies to mitigate stress. In the long term, these insights lead to improved safety standards and operational efficiencies in electrical systems.

Conclusion

In summary, the Cable Heat Pressure Test serves as a vital procedure in the evaluation of electrical cables. As our reliance on complex electrical systems continues to grow, so does the importance of ensuring that the components within these systems can withstand the rigors of their operational environments. By conducting rigorous testing and analyzing the results, engineers and manufacturers can confidently produce cables that meet safety and performance standards. Through the integration of such testing protocols, the electrical industry can not only enhance existing technologies but also innovate new solutions that align with the advancing demands of modern society.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy