electronic tensile testing machine suppliers

The Rise of Electronic Tensile Testing Machine Suppliers in Advanced Manufacturing

In today's fast-paced world of advanced manufacturing, the demand for precise and reliable materials testing continues to grow. One of the cornerstones of this testing process is the electronic tensile testing machine, a crucial tool used to evaluate the mechanical properties of materials. As industries evolve, so too do the suppliers of these essential machines, who are pivotal in ensuring that manufacturers can maintain quality and safety standards in their products.

Understanding Electronic Tensile Testing Machines

Electronic tensile testing machines are sophisticated devices designed to apply controlled tension to materials until they break. These machines provide crucial data, including tensile strength, yield strength, elongation, and modulus of elasticity. This information is vital in sectors such as aerospace, automotive, construction, and consumer goods, where material integrity cannot be compromised.

The shift from manual to electronic machines has revolutionized the testing process. Modern electronic tensile testing machines are equipped with computer interfaces and advanced software, which not only streamline data collection but also enable real-time analysis and reporting. This significant enhancement allows manufacturers to make informed decisions quickly, improving both efficiency and productivity.

The Role of Suppliers in the Industry

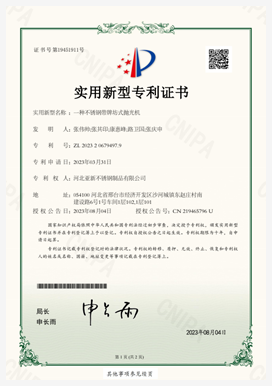

With the increasing complexity and specialization of materials, the role of electronic tensile testing machine suppliers has grown significantly. These suppliers provide not only the machines themselves but also offer maintenance, calibration, and training services essential for optimal performance. Their expertise is critical in ensuring that manufacturers can achieve accurate testing results consistently.

In recent years, the market for these machines has become more competitive, with numerous suppliers emerging globally. Suppliers now differentiate themselves by offering innovative products, extensive support services, and customizable solutions tailored to meet specific industry needs. This competition drives innovation, resulting in machines that are more user-friendly, efficient, and capable of performing a wider range of tests.

electronic tensile testing machine suppliers

Key Players in the Market

Among the leading suppliers of electronic tensile testing machines are companies renowned for their engineering excellence and commitment to quality. Established brands often dominate the market, but niche providers also play a key role by focusing on specific applications or industries. These suppliers invest heavily in research and development, pushing the boundaries of what is possible in materials testing technology.

For instance, several suppliers now integrate machine learning algorithms into their systems, enabling predictive maintenance and enhanced data analysis capabilities. This trend not only increases the lifespan of testing equipment but also minimizes downtime, essential for manufacturing operations that rely on continuous testing.

Challenges and Opportunities

While the prospects for electronic tensile testing machine suppliers are promising, challenges remain. Suppliers must adapt to ever-changing regulations and standards, as well as evolving customer needs. Additionally, the rise of alternative materials, such as composites and advanced alloys, necessitates continual innovation in testing methodologies.

Opportunities for growth abound, especially in emerging markets where rapid industrialization is taking place. As global demand for quality assurance rises, suppliers who can provide cutting-edge technology coupled with exceptional service stand to gain a significant share of the market.

Conclusion

In conclusion, electronic tensile testing machine suppliers play an indispensable role in the advanced manufacturing landscape. Their contributions ensure that industries remain equipped with the right tools to guarantee the integrity and performance of materials. As technology continues to advance, suppliers committed to innovation and customer service will not only thrive but will also shape the future of materials testing, ultimately driving progress across various sectors. The synergy between suppliers and manufacturers is crucial for achieving excellence in product development and quality assurance, paving the way for safer and more efficient products in an increasingly competitive marketplace.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy