Leading Manufacturer of Smoke Density Testing Equipment and Solutions

Smoke Density Tester Manufacturer The Key to Ensuring Safety and Quality

In industries ranging from construction to aerospace, understanding the behavior of materials under fire conditions is critical for safety and compliance. One essential tool in this field is the smoke density tester, which measures how much smoke a material emits when exposed to fire. This data is crucial for assessing fire risk and developing safer materials. As the demand for these sophisticated instruments grows, so does the number of manufacturers specializing in smoke density testers. This article explores the significance of smoke density testers, key features to look for, and what to consider when selecting a manufacturer.

The Importance of Smoke Density Testing

Smoke density testing is vital for numerous applications, especially for materials used in public spaces, transportation, and construction. The amount and toxicity of smoke produced during a fire can significantly affect evacuation procedures, fire-fighting efforts, and overall safety. Smoke density testers help manufacturers comply with stringent fire safety regulations by providing objective measurements that can influence material selection during the design phase.

Organizations such as ASTM International and ISO have established standards for smoke density testing, which manufacturers must adhere to when developing their products. These standards ensure that testing is consistent, reliable, and comparable across different materials and scenarios.

Key Features of Smoke Density Testers

When considering the purchase of a smoke density tester, several key features should be evaluated

1. Accuracy and Sensitivity The primary function of a smoke density tester is to deliver accurate and sensitive measurements of smoke density. A high-quality tester should provide precise readings that can detect even minor differences in smoke emissions.

2. Ease of Use User-friendly interfaces and straightforward operational procedures are essential, especially in complex industrial environments. A smoke density tester should be easy to set up and operate, allowing for quick testing and data acquisition.

3. Data Analysis Capabilities Modern smoke density testers often come equipped with advanced data analysis software. This feature enables manufacturers to analyze trends, compare results over time, and generate detailed reports, making it easier to meet compliance requirements.

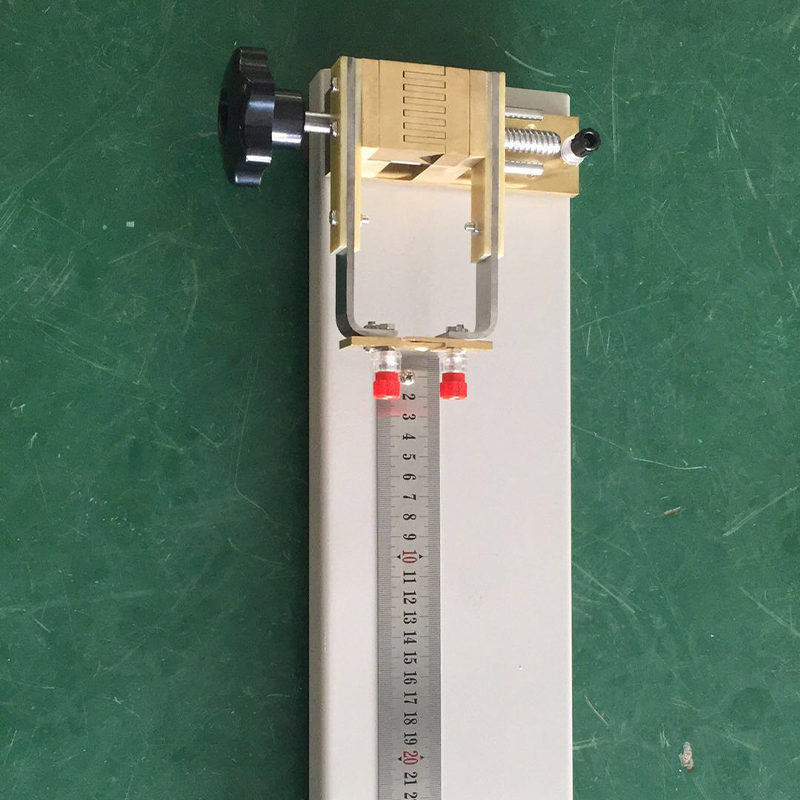

smoke density tester manufacturer

4. Durability and Reliability Given the harsh conditions under which these testers often operate, durability is paramount. A robust design will ensure that the instruments can withstand rigorous use without compromising accuracy.

5. Compliance with Standards Ensure that the manufacturer’s testers meet established industry standards. Compliance not only guarantees quality but also helps facilitate certification processes for the materials being tested.

Selecting a Smoke Density Tester Manufacturer

When choosing a smoke density tester manufacturer, consider the following factors to ensure you make the best decision

- Reputation Look for manufacturers with a proven track record of producing high-quality smoke density testers. Research customer reviews and ask for references to gauge the manufacturer’s credibility.

- Technical Support Reliable technical support is crucial for troubleshooting and maintenance. Make sure the manufacturer provides comprehensive support, including training, documentation, and assistance with data interpretation.

- Customization Options Some manufacturers offer customizable testing solutions tailored to specific industry needs. If your organization has unique requirements, consider manufacturers that provide bespoke designs.

- After-Sales Service A robust after-sales service, including warranties and maintenance plans, can make a significant difference in long-term satisfaction with the product.

Conclusion

Smoke density testers play a vital role in ensuring the safety and integrity of materials in various industries. As the demand for these devices grows, selecting the right manufacturer becomes critical. By focusing on accuracy, ease of use, compliance with standards, and strong after-sales support, companies can make informed decisions that enhance their fire safety protocols and overall product quality. Ultimately, investing in high-quality smoke density testing equipment is not just about compliance; it is about fostering a culture of safety and responsibility in the face of fire hazards.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy