cable crosslinking machine manufacturers

Understanding Cable Crosslinking Machine Manufacturers

In today's fast-paced industrial environment, the demand for high-quality cable production has surged. One of the pivotal technologies in this sector is the cable crosslinking process, which enhances the properties of cables, making them more heat-resistant, durable, and safe. Cable crosslinking machines are key players in this process, providing manufacturers with the tools they need to produce superior cables. With this rising demand, it's essential to understand what to look for in cable crosslinking machine manufacturers.

The Importance of Cable Crosslinking

Cable crosslinking refers to the process of chemically bonding the molecular chains of polymers, which results in a more robust material. This is particularly important for insulation in various cables, including those used in automotive, aerospace, and construction applications. The crosslinking process improves the thermal stability and chemical resistance of the cables, making them suitable for harsh environments. Therefore, the choice of crosslinking technology and, subsequently, the machine used for this process plays a critical role in determining the quality of the final product.

What to Look for in Manufacturers

1. Experience and Reputation When choosing a cable crosslinking machine manufacturer, it's vital to consider their experience in the industry. Established manufacturers with a solid reputation tend to have a proven track record of delivering reliable and efficient machines. Researching customer reviews and case studies can provide insights into the manufacturer’s reliability.

2. Technology and Innovation The cable manufacturing industry is fast-evolving, with new technologies continually emerging. Leading manufacturers invest in research and development to ensure their machines incorporate the latest innovations. This might include advancements in automation, energy efficiency, and integration with Industry 4.0 solutions.

cable crosslinking machine manufacturers

3. Customization Capabilities Not all manufacturers offer the same capabilities. Some businesses may require specific features based on their product lines or production volumes. A good manufacturer should be able to customize machines according to the unique needs of their clients, whether it involves modifying the machine's capacity or its technological features.

4. Quality and Standards Quality assurance is critical in cable manufacturing. Ensure that the manufacturer adheres to international quality standards, such as ISO certifications. This not only guarantees the machine's performance but also ensures that it complies with safety regulations in various markets.

5. After-Sales Support The relationship with a manufacturer shouldn’t end with the purchase. Look for companies that offer comprehensive after-sales support, including maintenance services, training for staff, and readily available spare parts. This support is crucial for minimizing downtime and ensuring that production runs smoothly.

6. Cost Efficiency While it’s important to invest in quality machinery, cost-effectiveness should also be a priority. Compare pricing across different manufacturers and weigh it against the features and benefits offered. The cheapest option may not always provide the best value in the long run.

Conclusion

Choosing the right cable crosslinking machine manufacturer is essential for ensuring the production of high-quality cables that meet industry standards. By considering factors such as experience, technology, customization, quality assurance, after-sales support, and cost efficiency, manufacturers can make informed decisions that enhance their operational performance and product quality. In an industry where precision and reliability are paramount, partnering with a reputable manufacturer can make all the difference.

-

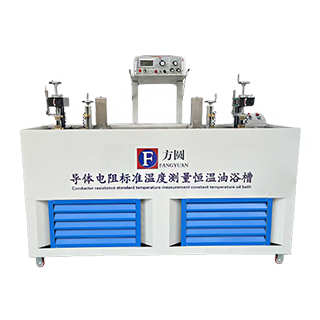

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy