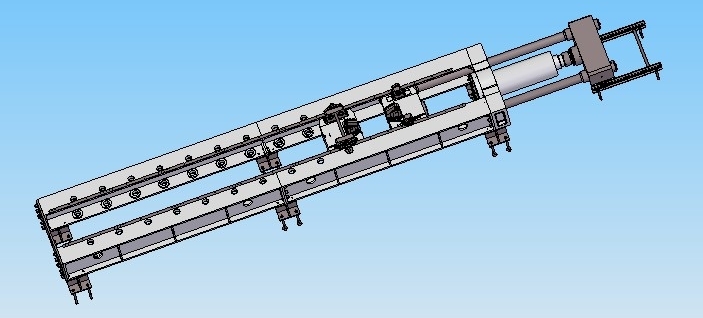

TXWL-600 Electro-Hydraulic Servo Horizontal Tensile Testing Machine

Bayanin Samfura

TXWL-600 electro-hydraulic servo a kwance tensile gwajin inji rungumi dabi'ar firam tsarin, guda sanda biyu-aiki piston Silinda yin gwajin karfi, da kuma kwamfuta kula da tsarin gane atomatik iko da gwajin tsari ta sarrafa servo bawul da sauran aka gyara, da gwajin. Ana tattara bayanai daidai ta hanyar firikwensin kaya kuma ana aika su zuwa kwamfutar, tsarin yana bincika ta atomatik, aiwatarwa da adana sakamakon gwajin, kuma firinta na iya buga rahoton gwajin da ake buƙata kai tsaye. Ana amfani da wannan na'ura galibi don gwajin juzu'i na igiya na karfe, samar da zamani ne na bincike da koyarwa na kimiyya da sauran masana'antu don biyan buƙatun na'urorin gwaji masu kyau.

Bayanin Injin

1.Tsarin mai watsa shiri

Babban ɓangaren injin ya ƙunshi babban injin injin, wurin zama na silinda, silinda mai, katako mai motsi, wurin zama na gaba da na baya da firikwensin kaya. Yana iya aiwatar da gwajin tensile tare da matsakaicin nauyin 600kN akan samfurin.

The main frame adopts a steel plate welded structure. The front end of the frame is equipped with an oil cylinder seat and an oil cylinder, and the rear end is fixed by a sealing plate to form a closed frame.The load sensor is installed on the moving crossbeam and connected to the piston rod through the ball hinge mechanism, and the moving crossbeam is connected to the front chuck seat through the tie rod. When the piston is working, it pushes the moving crossbeam forward to drive the front chuck seat to move. The rear chuck seat is moved electrically on the main frame through a guide wheel, and the main frame is equipped with a series of pin holes with a 500mm interval, after which the rear chuck seat is moved to a suitable position, the bolt is fixed.

Wurin gwajin yana sanye da murfin kariya, wanda zai iya kare lafiyar ma'aikatan gwajin yadda ya kamata.

2.Tsarin tushen mai

The hydraulic system adopts differential circuit, which can save the test preparation time to the maximum when the test requirements are met. The oil source system adopts pressure following system, and the pressure of oil source system increases with the increase of load, which can effectively save energy.The pumping station adopts servo valves and low-noise plunger pumps, equipped with precision oil filters not greater than 5μm, the pressure of the system is controlled by the overflow valve. The whole system is designed according to the principle of energy-saving and simple layout. The oil tank is equipped with electronic oil temperature and oil level gauges, high pressure oil filter, air filter and other protection and indication devices with oil temperature, liquid level and oil resistance. According to the requirements of the oil source, the oil source is equipped with air cooling device.

3.Sashen Lantarki

An tsara tsarin sarrafa wutar lantarki a cikin wurin gwajin gwaji, kuma akwai na'ura mai aiki da aka kera ta musamman don bayyana kowane nau'in ayyuka a kallo. Abubuwan da aka haɗa na lantarki na shahararren alamar duniya ne, tare da ingantaccen aiki da ingantaccen inganci.

Tsarin Software:

(1) Dangane da tsarin aiki na Windows XP tare da ayyukan shirye-shirye, ikon sarrafa ƙarfin gwajin daidai-ƙira, sarrafa matsuguni daidai-da-wane, riƙe ƙarfin gwaji, riƙewar matsuguni da sauran hanyoyin gwaji ana iya haɗa su ta yadda ake so don biyan buƙatun hanyoyin gwaji daban-daban. zuwa matsakaicin iyaka, kuma don gane nau'ikan nunin bayanai, zane mai lanƙwasa, sarrafa bayanai, adanawa da ayyukan bugu da ake buƙata don gwajin.

(2) Aika siginar sarrafawa zuwa bawul ɗin servo ta cikin kwamfutar don sarrafa buɗewa da jagorar bawul ɗin servo, ta haka ne ke sarrafa kwararar cikin silinda, da fahimtar sarrafa ƙarfin gwajin daidai-daidai, ƙaura daidai-daidai, da sauransu. .

(3) An sanye shi da madaukai biyu na rufaffiyar madauki na ƙarfin gwaji da ƙaura.

(4) It has complete file operation functions, such as test reports, test parameters, and system parameters can all be stored as files.

(5) Babban dubawa yana da duk ayyukan aikin yau da kullun na gwajin, kamar shigarwar bayanan samfurin, zaɓin samfurin, zane mai lanƙwasa, nunin bayanai, sarrafa bayanai, ƙididdigar bayanai, aikin gwaji, da sauransu. Aikin gwajin yana da sauƙi kuma sauri.

(6) Ana iya fitar da bayanan zuwa firinta don buga rahoton gwaji.

(7) Gudanar da tsarin tsarin, sigogin tsarin duk suna buɗewa ga ƙwararrun masu amfani, tabbatar da sassauci da amincin tsarin.

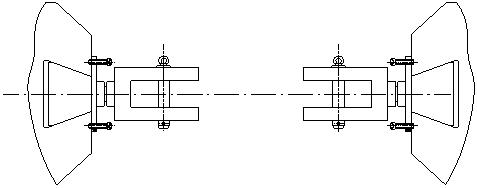

4.Test Na'urorin haɗi

An yi sanye da na'urorin gwajin igiya na waya (duba ƙasa) da sauran na'urorin haɗi ana kera su bisa ga ma'aunin da mai amfani ya bayar ko buƙatun tensile na samfurin.

5.Na'urorin Kare Tsaro

(1) Kariyar wuce gona da iri lokacin da ƙarfin gwajin ya wuce 2% zuwa 5% na matsakaicin ƙarfin gwaji ko ƙimar da aka saita.

(2) Kariyar bugun jini lokacin da piston ya motsa zuwa matsayi iyaka.

(3) Tare da zafin mai, matakin ruwa da kariyar juriyar mai da na'urorin nuni.

(4) Wurin gwaji yana da murfin kariya don hana samfurin daga karya da fadowa.

(5) Lokacin da gaggawa ta faru, danna maɓallin dakatar da gaggawa akan majalisar kulawa kai tsaye

Sigar Fasaha

1.Maximum gwajin ƙarfin: 600kN

2.Test ƙarfin ma'auni: 10kN ~ 600kN

3.Relative error of the indicated value of the test force: ≤±1% of the indicated value

4.Tensile gwajin sarari (ban da bugun jini): 20mm ~ 12000mm

5.Bugu da ƙari: 1000mm

6.Maximum gudun aiki na piston: 100 mm / min

7.Deformation extensometer daidaito: 0.01mm

8.The girma na babban inji (mm): 16000 (L) x 1300 (W) x 1000 (H) (ban da m murfin)