ינו . 09, 2025 12:28

Back to list

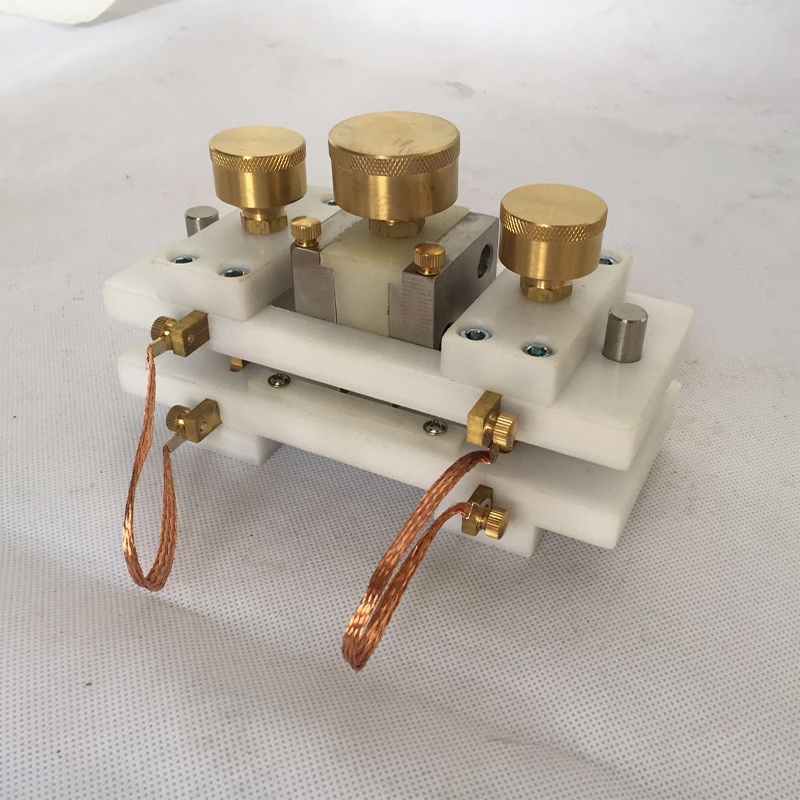

cable combustion testing machine

In industrial settings where safety is paramount, the cable combustion testing machine stands as a crucial tool in ensuring fire resistance and durability of cable products. As an instrument dedicated to replicating extreme conditions that cables might encounter, its role in fire safety tests is unmatched. Drawing from real-world expertise, my years of experience in the field, and authoritative industry insights, I can affirm the indispensable nature of this machine in modern safety standards.

The rigorous protocols established by authoritative agencies highlight the level of trust placed in these machines. Standards, such as the IEC 60332 or UL 1581, have demanding requirements. Adhering to these standards, which involve thorough testing via the combustion machine, ensures that manufacturers deliver high-quality cables. Investing in machines that align with such stringent guidelines is paramount for any reputable manufacturer committed to product excellence and safety. Trustworthiness in this context goes beyond the machine's specifications. It is reflected in the certifications provided post-testing. Companies using reliable cable combustion testing machines can produce certification reports that confirm compliance with global safety standards. These reports are not just paper; they represent a commitment to safety and reliability, offering peace of mind to end-users. In conclusion, the cable combustion testing machine is integral to the advancement of cable safety and technology. Manufacturers dedicated to incorporating these machines into their testing processes do not only align with industry standards but also set themselves apart as leaders in innovation and safety. With its unmatched ability to provide critical insights into the flammability and performance of cable materials, this machine assures clients of the highest level of safety and reliability—a true testament to its indispensability in today's safety-conscious world.

The rigorous protocols established by authoritative agencies highlight the level of trust placed in these machines. Standards, such as the IEC 60332 or UL 1581, have demanding requirements. Adhering to these standards, which involve thorough testing via the combustion machine, ensures that manufacturers deliver high-quality cables. Investing in machines that align with such stringent guidelines is paramount for any reputable manufacturer committed to product excellence and safety. Trustworthiness in this context goes beyond the machine's specifications. It is reflected in the certifications provided post-testing. Companies using reliable cable combustion testing machines can produce certification reports that confirm compliance with global safety standards. These reports are not just paper; they represent a commitment to safety and reliability, offering peace of mind to end-users. In conclusion, the cable combustion testing machine is integral to the advancement of cable safety and technology. Manufacturers dedicated to incorporating these machines into their testing processes do not only align with industry standards but also set themselves apart as leaders in innovation and safety. With its unmatched ability to provide critical insights into the flammability and performance of cable materials, this machine assures clients of the highest level of safety and reliability—a true testament to its indispensability in today's safety-conscious world.

Next:

Latest news

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy