Testing Conductor Resistance in China for Enhanced Electrical Performance and Safety

Understanding Conductor Resistance Testing in China

Conductor resistance testing is a critical aspect of ensuring the integrity and performance of electrical systems. With China's rapid technological advancement and booming infrastructure projects, the need for rigorous testing methodologies has become increasingly important. This article explores the significance of conductor resistance testing, the methodologies employed, and the implications for the electrical industry in China.

The Importance of Conductor Resistance Testing

Conductor resistance testing plays a vital role in the assessment of electrical connectivity and the overall efficiency of electrical systems. Resistance in conductors can lead to energy losses, overheating, and ultimately, system failures. In environments where large amounts of power are transmitted, such as in power plants or industrial facilities, even a minor increase in conductor resistance can have significant implications, leading to inefficiencies and increased operational costs.

In China, which is investing heavily in renewable energy, smart grids, and urban infrastructure, the need to maintain high-performance electrical systems is paramount. With the rise of electric vehicles (EVs) and smart technologies, conducting resistance tests ensures that the components can handle increased loads and perform reliably over time.

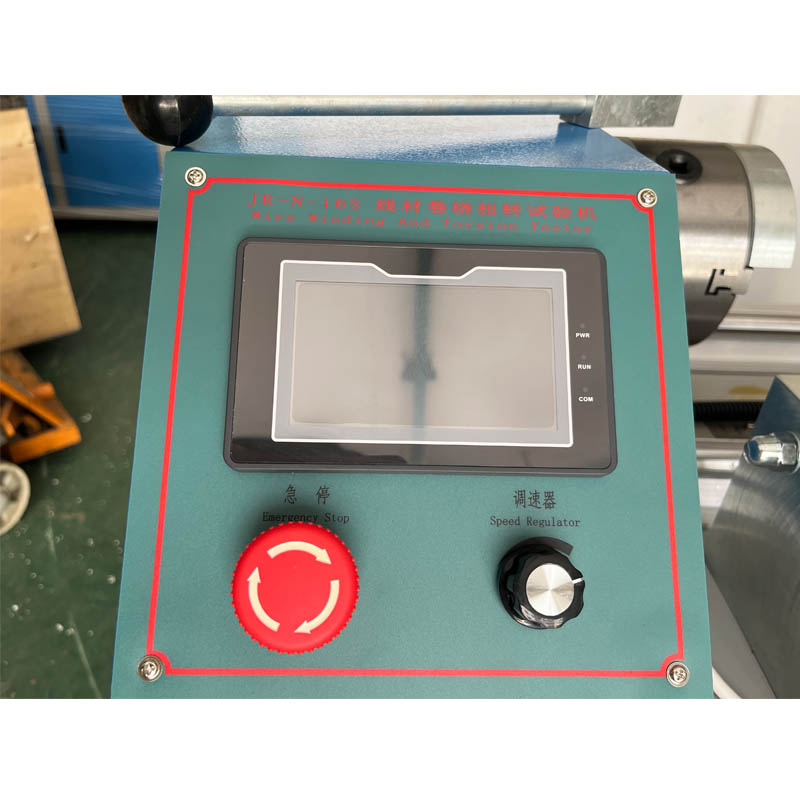

Methodologies for Conducting Resistance Testing

In China, several methodologies are employed to conduct resistance testing on electrical conductors. The most common technique is the four-wire (Kelvin) measurement method. This technique mitigates the effects of lead and contact resistances, allowing for accurate measurement of the conductor's resistance.

1. Four-Wire Measurement This method uses two pairs of leads—one pair supplies a current, while the other pair measures the voltage drop across the conductor. By applying Ohm’s Law (R = V/I), where R is resistance, V is voltage, and I is current, the true resistance of the conductor can be effectively calculated.

china conductor resistance test

2. Low-Frequency AC Testing This method utilizes a low-frequency alternating current to assess resistance, which helps in identifying skin effect and proximity effect issues. This technique is particularly useful in high-frequency applications, where traditional testing methods may yield inaccurate results due to varying resistances at different frequencies.

3. Temperature Correction Since resistance is temperature-dependent, testing must account for the temperature of the conductor during measurement. Typically, conductors are tested at a standard reference temperature (often 20°C), and corrections are made to ensure accuracy in varying conditions.

4. Visual and Mechanical Inspection While electrical tests are crucial, mechanical integrity must also be verified. Conductors are visually inspected for any signs of wear, corrosion, or physical damage. Mechanical testing may include tensile tests to gauge the conductor’s robustness.

Implications for the Electrical Industry

The implications of effective conductor resistance testing in China are vast. The electrical industry is under constant pressure to innovate and improve efficiencies, especially as the country transitions towards greener energy and smart technologies. By implementing comprehensive testing protocols, manufacturers can not only enhance the reliability of their products but also ensure compliance with national and international standards.

Moreover, improvements in conductor resistance testing methods can lead to longer lifespan products, reduced maintenance costs, and enhanced safety. For industries such as transportation, telecommunications, and public utilities, reliable conductors mean less downtime and more efficient energy distribution.

Conclusion

As China continues to expand its electrical infrastructure and integrate advanced technologies, the role of conductor resistance testing will remain crucial. It is essential for engineers and technicians to adopt robust testing methodologies to ensure that conductors perform at optimal levels. By prioritizing rigorous testing protocols, the Chinese electrical industry can bolster its reputation for quality, reliability, and innovation, ultimately contributing to the nation’s goals of sustainable development and technological advancement. The future holds great potential for advancements in testing practices, ensuring that the backbone of China's electrical infrastructure remains strong and efficient.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy