resistance tests companies

Resistance Tests Ensuring Quality in Manufacturing and Construction

In the modern world where quality standards are paramount, resistance tests play a crucial role in various industries, particularly in manufacturing and construction. These tests ensure that materials and products are capable of withstanding adverse conditions, which is vital not only for performance but also for safety.

Resistance testing typically involves assessing a product's durability against a range of potential challenges, including physical stress, temperature fluctuations, chemical exposure, and electrical currents. Different industries have specific standards and methodologies for these tests, ensuring that every component meets the necessary safety and quality requirements.

The Importance of Resistance Testing in Manufacturing

In the manufacturing sector, companies rely heavily on resistance tests to ensure that their products will perform effectively under expected usage conditions. For example, electronics manufacturers conduct resistance tests on circuit boards and components to verify that they can handle electrical currents without failure. This is paramount in preventing short circuits or equipment malfunctions, which can not only lead to financial losses but also compromise safety.

Similarly, the automotive industry employs rigorous resistance tests for various components like brakes, suspensions, and engine parts. These components must withstand tremendous forces and varying environmental conditions. Conducting comprehensive testing helps manufacturers identify weaknesses in materials, allowing for adjustments before mass production.

Resistance Testing in Construction

In the construction sector, resistance testing is equally critical. Building materials such as concrete, steel, and composites are subjected to tests that gauge their strength and resilience. For instance, concrete is often tested for compressive strength, which ensures it can bear the loads of buildings and infrastructure. Similarly, steel is assessed for yield strength, helping builders to determine its suitability for use in structural elements.

Resistance tests also evaluate a material's performance against natural elements. For example, materials used in coastal constructions must be resistant to saltwater corrosion and high winds. These tests are essential for ensuring that structures meet building codes and can endure harsh environmental conditions over time, thus protecting investments and lives.

resistance tests companies

Industry Standards and Certifications

Various organizations establish standards for resistance testing that companies must adhere to in order to ensure quality and safety. The American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO) are two prominent bodies that provide guidelines for testing procedures and quality assurance.

Certifications from these organizations are often a requirement for companies seeking to demonstrate the reliability of their products. Passing resistance tests not only helps in product development but also enhances a company's reputation, allowing for greater competitiveness in the market. It reassures clients and stakeholders that products have been rigorously evaluated for quality and safety.

Emerging Trends in Resistance Testing

As technology continues to advance, so do the methods of resistance testing. The integration of artificial intelligence and machine learning is beginning to revolutionize how companies conduct these tests. Predictive analytics can help in identifying potential failure points in materials before they are even tested, streamlining the testing process and improving accuracy.

Furthermore, with the growing emphasis on sustainability, many companies are beginning to incorporate resistance tests that evaluate the environmental impact of their materials. This shift is part of a broader commitment to develop products that are not only durable but also eco-friendly.

Conclusion

In conclusion, resistance tests are an indispensable aspect of quality assurance in manufacturing and construction. They not only ensure that products can withstand the rigors of use but also play a pivotal role in maintaining safety standards. As industries continue to evolve and face new challenges, resistance testing will remain a foundational practice for ensuring that products are reliable, durable, and safe for consumers, ultimately contributing to the longevity of infrastructure and industrial products alike.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

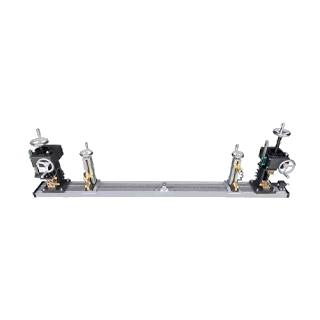

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy