Resistivity Measurement Solutions from Leading Manufacturer for Accurate Testing and Quality Control

Understanding Resistivity Tester Factories An Insight into Manufacturing Processes

In the realm of electrical engineering and material science, resistivity testers play a pivotal role in measuring the electrical resistance of various materials. These devices are essential for a wide range of applications, from industrial manufacturing to laboratory research. The development and production of resistivity testers typically take place in specialized factories dedicated to precision engineering and quality assurance.

Understanding Resistivity Tester Factories An Insight into Manufacturing Processes

The production process of a resistivity tester begins with the design phase, where engineers use computer-aided design (CAD) software to create detailed specifications and prototypes. This stage involves a thorough understanding of the underlying physics and the specific requirements of the end-users. Once the design is finalized, components such as measurement electrodes, circuit boards, and housing materials are sourced from trusted suppliers. Quality control checks are implemented at every stage to ensure that each component meets the required specifications.

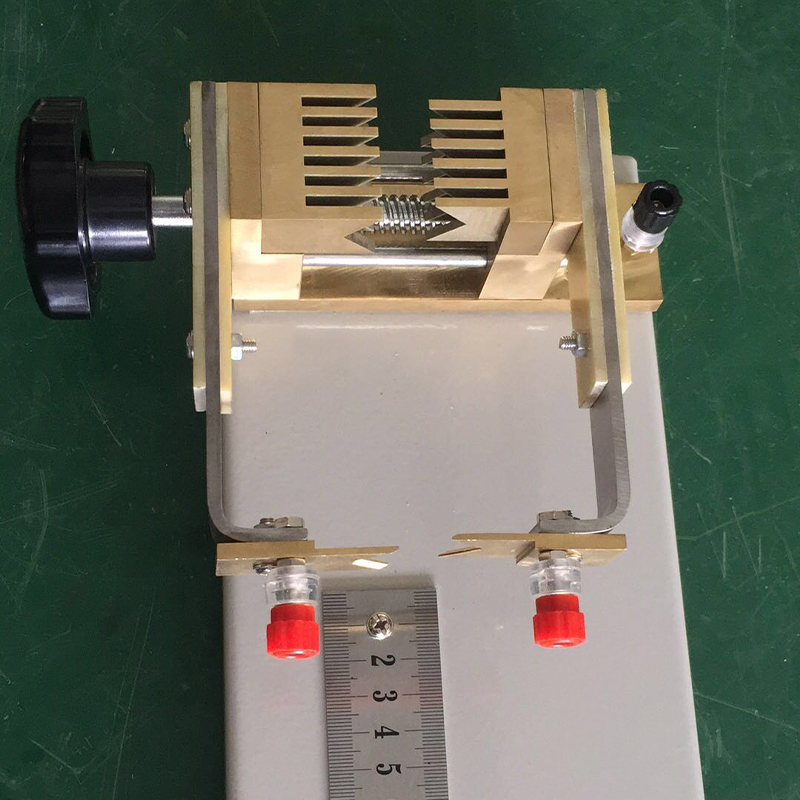

resistivity tester factory

After sourcing materials, the assembly process begins. This often involves precision soldering, the integration of sensitive electronic components, and thorough testing of each unit. Automated assembly lines can enhance efficiency, but many factories still rely on manual assembly for certain sensitive components to maintain high quality. After assembly, each resistivity tester undergoes rigorous testing to ensure accuracy and reliability. This typically includes calibration against known resistivity standards and performance assessments in various environmental conditions.

Moreover, customer feedback plays an essential role in the iterative design and production process. Many resistivity tester factories maintain close relationships with their clients, gathering insights on usability and performance. This feedback loop allows manufacturers to continuously improve their products, introducing innovations that address emerging needs in the market.

Another vital aspect of resistivity tester factories is adhering to international safety and compliance standards. Since these devices are often used in critical applications, manufacturers must ensure that their products meet regulations that pertain to electrical safety, environmental impact, and performance reliability. Certification from recognized organizations helps build trust with customers and enhances the factory’s reputation in the industry.

In conclusion, resistivity tester factories are integral to producing reliable and accurate measurement devices. Through meticulous design, quality sourcing, precise assembly, and rigorous testing, these factories contribute significantly to advancements in electrical engineering and materials science. As demand for high-performance testing devices continues to grow, these factories will undoubtedly play a crucial role in shaping the future of technology and innovation. The continuous improvement driven by customer feedback and adherence to safety standards will keep these manufacturers at the forefront of the industry.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy