tensile strength tester manufacturers exporters

A Comprehensive Overview of Tensile Strength Tester Manufacturers and Exporters

In today’s industrial landscape, the demand for precise and reliable testing equipment has never been higher. Among the essential tools for material testing is the tensile strength tester, which is pivotal in determining how materials will react under tension. Its importance spans various industries, including construction, manufacturing, and materials science, making manufacturers and exporters of these devices crucial players in the market.

What is a Tensile Strength Tester?

A tensile strength tester, often referred to as a tensile tester or universal testing machine (UTM), is designed to determine the tensile strength of materials. This involves applying a controlled force to a specimen until it deforms or breaks, measuring the force applied and the extent of elongation. This data is essential for engineers and material scientists to assess material properties, ensuring that they meet specific safety and performance standards.

The Role of Manufacturers

Manufacturers of tensile strength testers play a significant role in ensuring the accuracy, efficiency, and innovation of these devices

. They employ advanced technologies, including digital displays, automated systems, and precision load cells, to provide reliable results. Leading manufacturers continually invest in research and development to enhance the functionality of their testing machines, offering options for varied materials including metals, plastics, textiles, and composites.Features such as user-friendly interfaces, customizable test settings, and integrated software for data analysis are becoming standard as manufacturers strive to meet the evolving needs of their customers. Additionally, compliance with international standards, such as ISO and ASTM, is critical for manufacturers to ensure that their products are accepted globally.

tensile strength tester manufacturers exporters

Exporters in the Market

The global demand for tensile strength testers has led to a robust export market. Exporters facilitate the reach of high-quality testing equipment to countries where local manufacturing may be limited. They provide crucial support in navigating the complexities of international trade, including logistics, customs regulations, and market entry strategies.

Countries known for their advanced manufacturing sectors, such as Germany, the United States, and Japan, are renowned exporters of tensile strength testers. These exporters not only supply state-of-the-art equipment but also offer calibration services, technical support, and training to ensure that users can maximize the functionality of their testers.

The Importance of Quality Assurance

When selecting a tensile strength tester, quality assurance becomes paramount. Reliable manufacturers and exporters implement stringent quality control measures, ensuring that their products are tested thoroughly before reaching the market. This commitment to quality helps prevent costly errors in material testing processes, ultimately safeguarding the integrity of safety-critical applications.

Conclusion

In conclusion, the role of tensile strength tester manufacturers and exporters in the global market cannot be overstated. As industries continue to evolve, the demand for advanced material testing solutions will grow. Manufacturers are tasked with innovating and enhancing the capabilities of tensile strength testers, while exporters play a critical role in making these essential tools accessible worldwide. By focusing on quality, innovation, and customer support, these entities contribute significantly to the advancement of industries reliant on material performance and safety. As industrial needs progress, the importance of reliable tensile strength testing will remain a cornerstone of engineering and manufacturing excellence.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

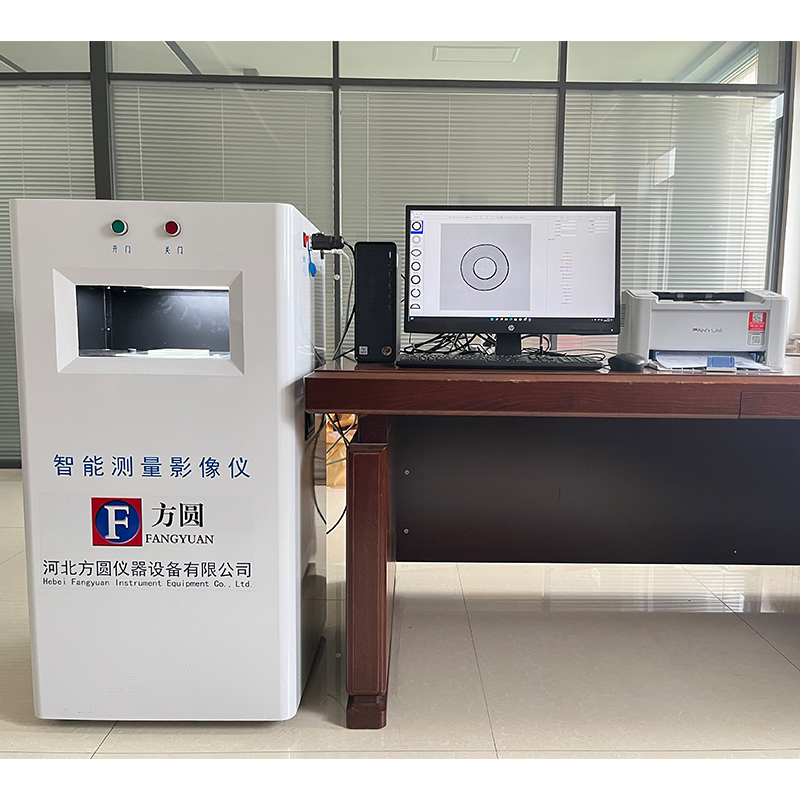

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy