יול . 04, 2024 02:40

Back to list

UV and IR Radiation Used in Cross-linking Equipment Manufacturing Plant

UV irradiation cross-linked equipment is a crucial component in various industries, including the medical field, electronics, and automotive sectors. This equipment is used to create cross-linked materials that have improved properties such as increased strength, durability, and chemical resistance. In this article, we will discuss the significance of UV irradiation cross-linked equipment and how it is vital in the manufacturing process.

UV irradiation cross-linked equipment is specifically designed to utilize ultraviolet light to induce cross-linking reactions in materials such as plastics, polymers, and resins. This process involves exposing the material to a controlled dose of UV light, which triggers the formation of covalent bonds between the polymer chains. These bonds create a three-dimensional network within the material, enhancing its physical and mechanical properties.

One of the main advantages of UV irradiation cross-linking is the ability to create materials with superior characteristics compared to conventional materials. For example, cross-linked polymers exhibit higher tensile strength, improved thermal stability, and enhanced chemical resistance, making them ideal for applications where durability and reliability are paramount. Additionally, the cross-linking process can be tailored to meet specific performance requirements, allowing manufacturers to customize materials for different applications.

UV irradiation cross-linked equipment is used in a wide range of industries, including the medical field, where it is utilized to produce medical devices, implants, and surgical equipment. Cross-linked materials are biocompatible, inert, and resistant to sterilization methods, making them suitable for use in medical applications Cross-linked materials are biocompatible, inert, and resistant to sterilization methods, making them suitable for use in medical applications Cross-linked materials are biocompatible, inert, and resistant to sterilization methods, making them suitable for use in medical applications Cross-linked materials are biocompatible, inert, and resistant to sterilization methods, making them suitable for use in medical applications

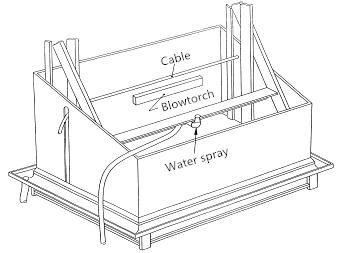

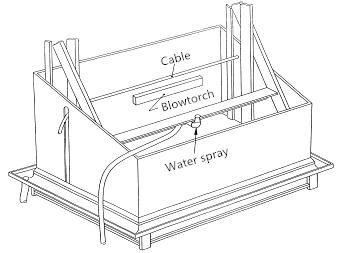

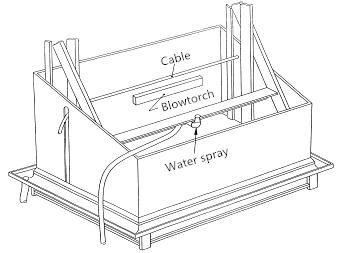

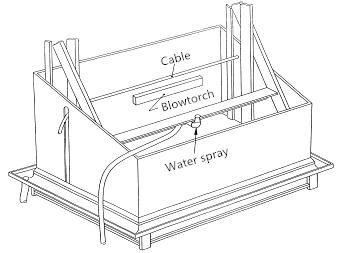

Cross-linked materials are biocompatible, inert, and resistant to sterilization methods, making them suitable for use in medical applications Cross-linked materials are biocompatible, inert, and resistant to sterilization methods, making them suitable for use in medical applications uv irradiation cross-linked equipment factory. In the electronics industry, UV cross-linked materials are used to create high-performance cables, insulating materials, and electronic components that require excellent mechanical and thermal properties.

Furthermore, UV irradiation cross-linked equipment plays a crucial role in the automotive sector, where it is used to manufacture automotive components such as hoses, seals, and gaskets. Cross-linked materials are resistant to automotive fluids, withstand high temperatures, and exhibit superior durability, making them ideal for use in demanding automotive applications. The use of UV irradiation cross-linked equipment ensures that automotive components meet stringent performance requirements and provide long-lasting reliability.

In conclusion, UV irradiation cross-linked equipment is a vital tool in the manufacturing process, enabling the production of high-performance materials with superior properties. Industries such as medical, electronics, and automotive rely on UV cross-linking technology to create materials that meet demanding performance requirements and deliver exceptional reliability. As technology continues to advance, the use of UV irradiation cross-linked equipment will become increasingly widespread, driving innovation and enhancing the capabilities of various industries. The versatility and effectiveness of UV cross-linking make it an indispensable tool for manufacturers seeking to improve the performance and durability of their products.

uv irradiation cross-linked equipment factory. In the electronics industry, UV cross-linked materials are used to create high-performance cables, insulating materials, and electronic components that require excellent mechanical and thermal properties.

Furthermore, UV irradiation cross-linked equipment plays a crucial role in the automotive sector, where it is used to manufacture automotive components such as hoses, seals, and gaskets. Cross-linked materials are resistant to automotive fluids, withstand high temperatures, and exhibit superior durability, making them ideal for use in demanding automotive applications. The use of UV irradiation cross-linked equipment ensures that automotive components meet stringent performance requirements and provide long-lasting reliability.

In conclusion, UV irradiation cross-linked equipment is a vital tool in the manufacturing process, enabling the production of high-performance materials with superior properties. Industries such as medical, electronics, and automotive rely on UV cross-linking technology to create materials that meet demanding performance requirements and deliver exceptional reliability. As technology continues to advance, the use of UV irradiation cross-linked equipment will become increasingly widespread, driving innovation and enhancing the capabilities of various industries. The versatility and effectiveness of UV cross-linking make it an indispensable tool for manufacturers seeking to improve the performance and durability of their products.

Cross-linked materials are biocompatible, inert, and resistant to sterilization methods, making them suitable for use in medical applications Cross-linked materials are biocompatible, inert, and resistant to sterilization methods, making them suitable for use in medical applications

Cross-linked materials are biocompatible, inert, and resistant to sterilization methods, making them suitable for use in medical applications Cross-linked materials are biocompatible, inert, and resistant to sterilization methods, making them suitable for use in medical applications uv irradiation cross-linked equipment factory. In the electronics industry, UV cross-linked materials are used to create high-performance cables, insulating materials, and electronic components that require excellent mechanical and thermal properties.

Furthermore, UV irradiation cross-linked equipment plays a crucial role in the automotive sector, where it is used to manufacture automotive components such as hoses, seals, and gaskets. Cross-linked materials are resistant to automotive fluids, withstand high temperatures, and exhibit superior durability, making them ideal for use in demanding automotive applications. The use of UV irradiation cross-linked equipment ensures that automotive components meet stringent performance requirements and provide long-lasting reliability.

In conclusion, UV irradiation cross-linked equipment is a vital tool in the manufacturing process, enabling the production of high-performance materials with superior properties. Industries such as medical, electronics, and automotive rely on UV cross-linking technology to create materials that meet demanding performance requirements and deliver exceptional reliability. As technology continues to advance, the use of UV irradiation cross-linked equipment will become increasingly widespread, driving innovation and enhancing the capabilities of various industries. The versatility and effectiveness of UV cross-linking make it an indispensable tool for manufacturers seeking to improve the performance and durability of their products.

uv irradiation cross-linked equipment factory. In the electronics industry, UV cross-linked materials are used to create high-performance cables, insulating materials, and electronic components that require excellent mechanical and thermal properties.

Furthermore, UV irradiation cross-linked equipment plays a crucial role in the automotive sector, where it is used to manufacture automotive components such as hoses, seals, and gaskets. Cross-linked materials are resistant to automotive fluids, withstand high temperatures, and exhibit superior durability, making them ideal for use in demanding automotive applications. The use of UV irradiation cross-linked equipment ensures that automotive components meet stringent performance requirements and provide long-lasting reliability.

In conclusion, UV irradiation cross-linked equipment is a vital tool in the manufacturing process, enabling the production of high-performance materials with superior properties. Industries such as medical, electronics, and automotive rely on UV cross-linking technology to create materials that meet demanding performance requirements and deliver exceptional reliability. As technology continues to advance, the use of UV irradiation cross-linked equipment will become increasingly widespread, driving innovation and enhancing the capabilities of various industries. The versatility and effectiveness of UV cross-linking make it an indispensable tool for manufacturers seeking to improve the performance and durability of their products. Latest news

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy