High-Quality Clamps for Tensile Testers | Reliable Manufacturers

Clamps for Tensile Testers Essential Components for Accurate Material Testing

Tensile testing is a fundamental procedure in material science, enabling researchers and manufacturers to understand the mechanical properties of various materials. A crucial component of any tensile testing setup is the clamps used to secure the specimen during the test. This article explores the significance of clamps, the types available in the market, and the role of manufacturers in providing reliable solutions for tensile testers.

Clamps for Tensile Testers Essential Components for Accurate Material Testing

Several types of clamps are commonly used in tensile testers, each designed to accommodate specific materials and test conditions. Wedge grips are among the most popular, utilizing a mechanical mechanism to pinch the specimen securely as force is applied. They are versatile and suitable for various material types, including metals and plastics. Hydraulic grips use fluid pressure to apply an even clamping force, making them ideal for high-strength materials or when dealing with larger samples. On the other hand, pneumatic clamps offer quick operation, which can enhance testing efficiency, particularly in high-throughput environments.

clamps for tensile testers manufacturers

Manufacturers of clamps for tensile testers play a significant role in ensuring that these tools meet the industry's highest standards of quality and precision. Leading manufacturers invest in research and development to innovate better designs, materials, and mechanisms that enhance the performance of tensile testing equipment. They often offer a wide range of products tailored to meet the specific needs of different sectors, including aerospace, automotive, and construction.

Furthermore, reputable clamp manufacturers not only provide high-quality products but also offer comprehensive support and guidance for their customers. They offer recommendations on the most suitable clamp types for specific applications, ensuring that users can achieve reliable and reproducible testing results. Many manufacturers also provide calibration services and technical support, which helps maintain the integrity and accuracy of the testing process over time.

In conclusion, clamps are indispensable components of tensile testing equipment. Their proper selection and use directly impact the accuracy of the mechanical properties measured during testing. As industries increasingly rely on precise data to inform material decisions, the role of high-quality clamps manufactured to meet stringent standards cannot be understated. Whether through innovative designs or technical support, manufacturers of clamps for tensile testers are essential partners in the pursuit of accurate and reliable material testing. As technology advances, we can expect further enhancements in clamp design, ultimately leading to more efficient and accurate tensile testing practices across various industries.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

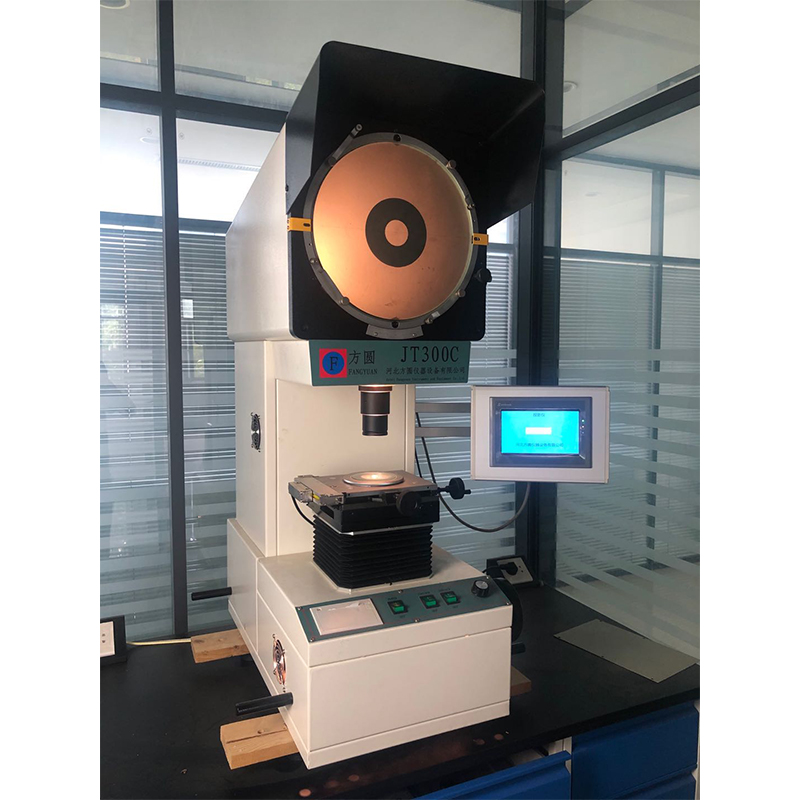

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy